Determination method for content of tricresyl phosphate flame retardants in rubber parts of electronic and electrical products

A kind of trimethyl phosphate, electronic and electrical technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of many rubber interferences, insoluble rubber, difficult qualitative and quantitative analysis, etc., to achieve high sensitivity, low detection limit, convenient Accurately Measured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

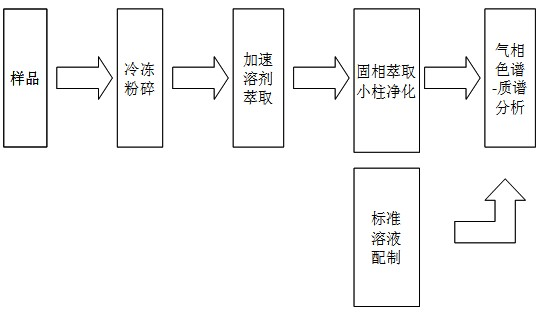

[0032] The detection method of the tricresyl phosphate flame retardant in the antistatic styrene-butadiene rubber mat provided by this embodiment, as attached figure 1 As shown, it mainly includes the following steps:

[0033] (1) Sample preparation

[0034] Freeze and crush the antistatic styrene-butadiene rubber mat until the maximum particle size is less than 0.5 mm, and mix well to obtain a uniform sample.

[0035] (2) Extraction of tricresyl phosphate flame retardants

[0036]Put 0.5g of anhydrous sodium sulfate at the bottom of the extraction tank, weigh about 1g of the pulverized rubber sample (accurate to 0.1mg), add 0.5g of activated copper powder, and the activation process is: put 5g of copper powder in Add 30mL of acetone-concentrated hydrochloric acid (the volume ratio of the two is 1:1, the concentrated hydrochloric acid is commercially available, its mass fraction is about 37%, the same below) mixed solution into 100mL dry ground Erlenmeyer flask, and turn on ...

Embodiment 2

[0057] The detection method of the tricresyl phosphate flame retardant in the EPDM rubber hose of the hydraulic press provided in this embodiment, as attached figure 1 As shown, it mainly includes the following steps:

[0058] (1) Sample preparation

[0059] Freeze and crush the EPDM rubber tube of the hydraulic press until the maximum particle size is less than 0.5mm, and mix well to obtain a uniform sample.

[0060] (2) Extraction of tricresyl phosphate flame retardants

[0061] Put 0.3g of anhydrous sodium sulfate at the bottom of the extraction tank, weigh about 1g of crushed rubber sample (accurate to 0.1mg), add 1.0g of activated silver powder, the activation process of silver powder is: put 5g of silver powder in 100mL Add 30mL of the mixed solution of acetone and (1+1) nitric acid (the volume ratio of the two is 1:1) into the dry ground-mouth Erlenmeyer flask, start the magnetic stirrer to stir vigorously for 5min, and then use the sand core funnel to suction filter....

Embodiment 3

[0083] The detection method of the tricresyl phosphate flame retardant in the temperature-resistant neoprene rubber ring provided by this embodiment, as attached figure 1 As shown, it mainly includes the following steps:

[0084] (1) Sample preparation

[0085] Freeze and crush the temperature-resistant neoprene ring until the maximum particle size is less than 0.5 mm, and mix well to obtain a uniform sample.

[0086] (2) Extraction of tricresyl phosphate flame retardants

[0087] Put 0.2g of anhydrous sodium sulfate at the bottom of the extraction tank, weigh about 1g of the pulverized rubber sample (accurate to 0.1mg), add 0.2g of activated copper powder, the activation process of copper powder is as follows: 5g of copper powder Place in a 100mL dry ground-mouth Erlenmeyer flask, add 30mL of acetone-concentrated hydrochloric acid (1:1) mixed solution, start the magnetic stirrer to stir vigorously for 10 min, and then use a sand core funnel to suction filter. Repeat this twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com