PC-ABS alloy for computer housing

A PC-ABS, computer shell technology, applied in the field of polymer alloys, can solve the problems of complex production control, complex composition, increased composition and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

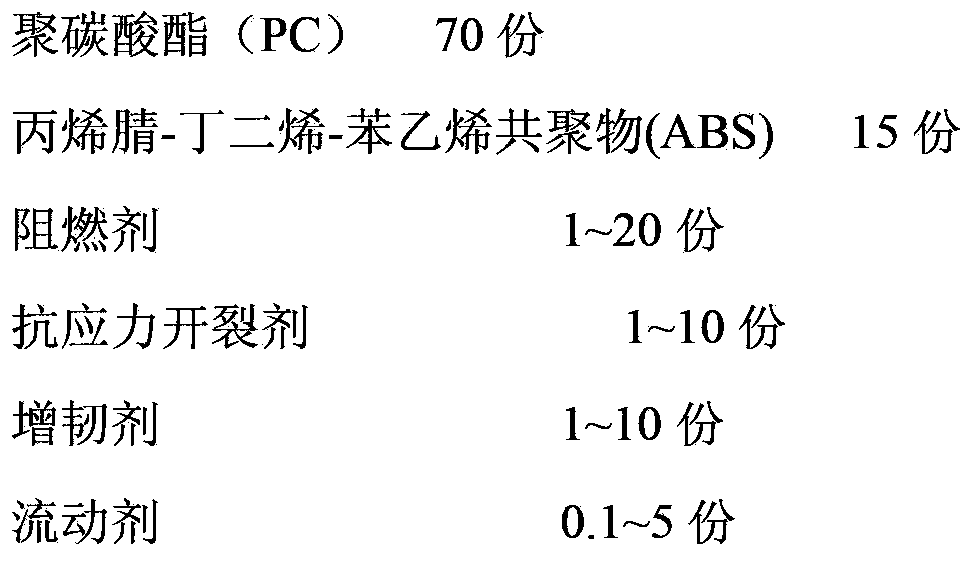

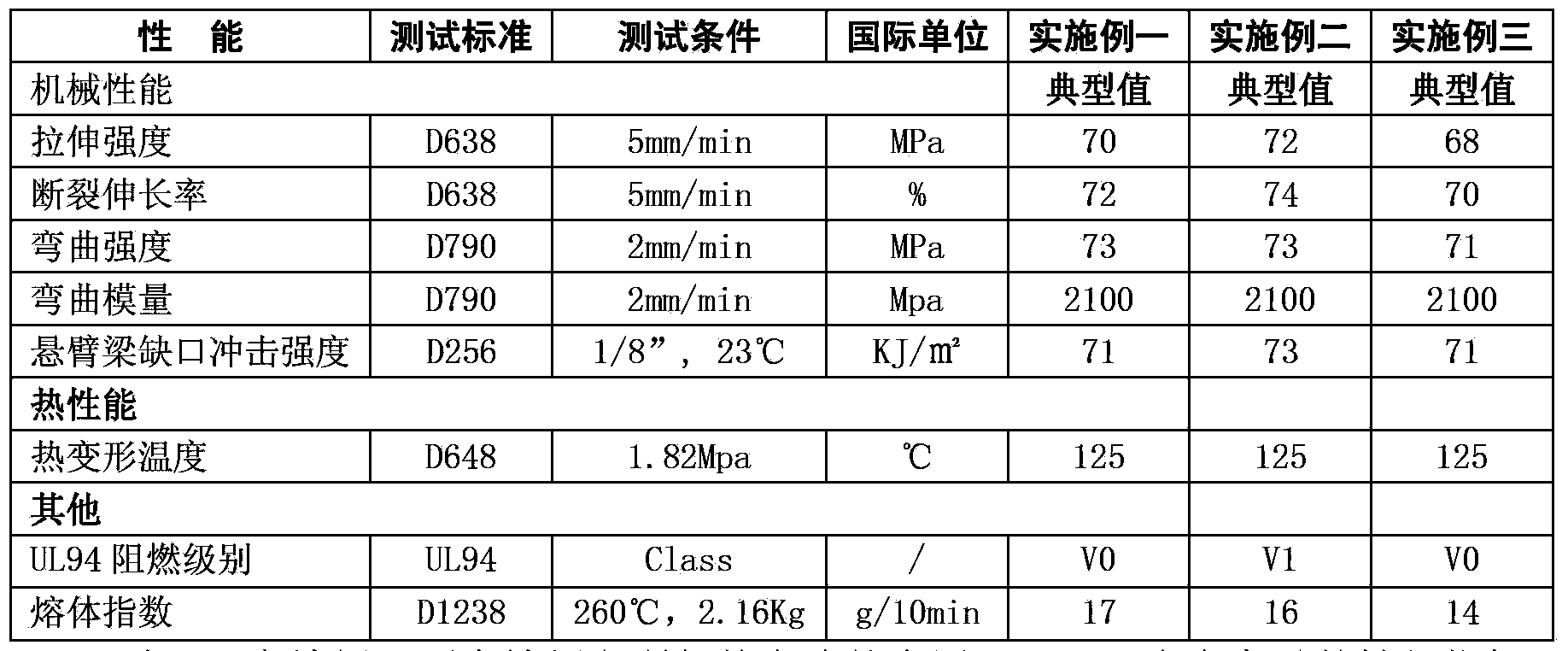

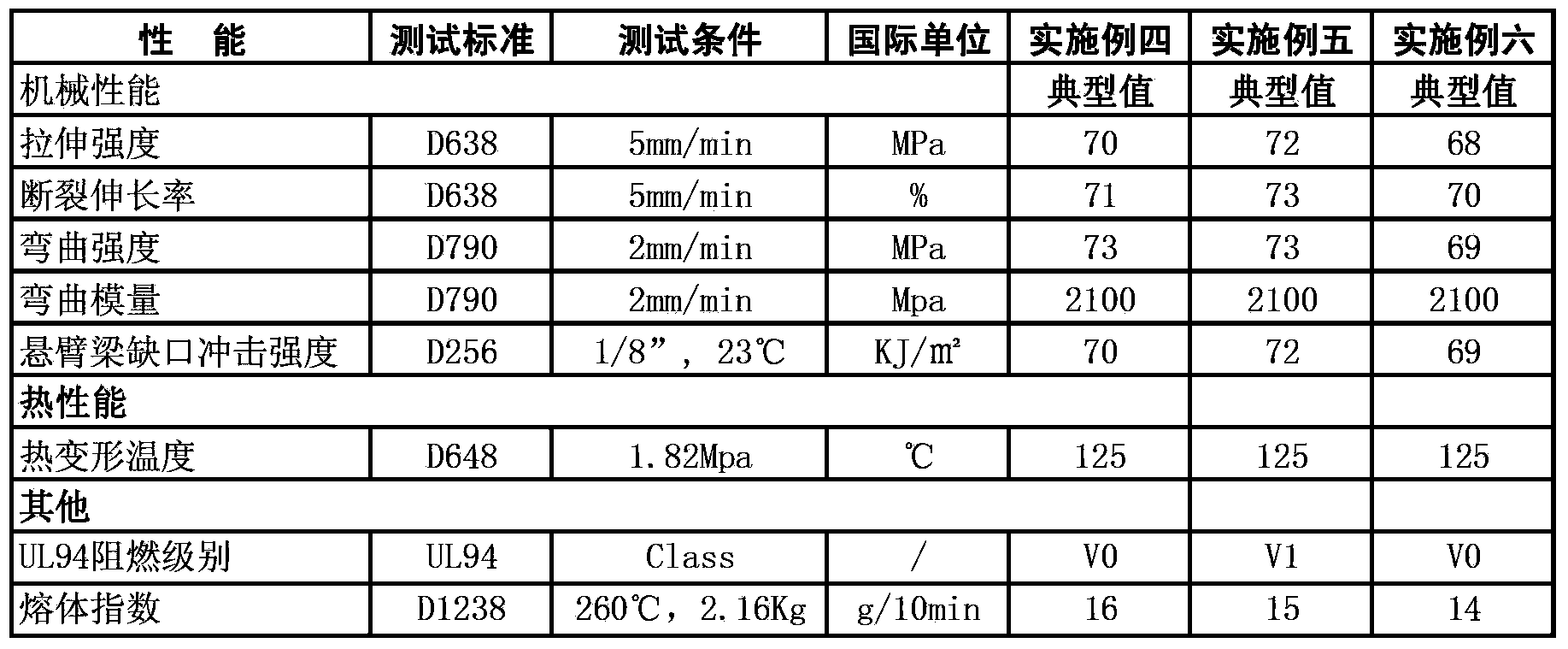

[0028] Embodiment: the formula of each embodiment is shown in table 1 and table 2, and the formula of described each embodiment is all in parts by weight. Simultaneously, the performance indications of PC-ABS alloy products for the computer casings obtained in each embodiment are listed in Table 3 and Table 4.

[0029] Table 1: Example 1 to Example 3 formulations

[0030] formula

Embodiment one

Embodiment two

Embodiment three

PC

70 copies

70 copies

70 copies

ABS

15 copies

15 copies

15 copies

Bisphenol A diphenyl phosphate

10 copies

4 parts

15 copies

Ethyl-hydrogenated nitrile-acrylate ternary copolymerization graft

3 copies

3 copies

3 copies

2 copies

2 copies

2 copies

Pentaerythritol Stearic Acid (PETS)

0.5 parts

0.5 parts

0.5 parts

[0031] Table 2: Embodiment four to embodiment six formula

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com