Heat-resistant and oil-resistant rubber hose

An oil-resistant and heat-resistant technology, applied in the direction of hoses, pipes, pipes/fittings/fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

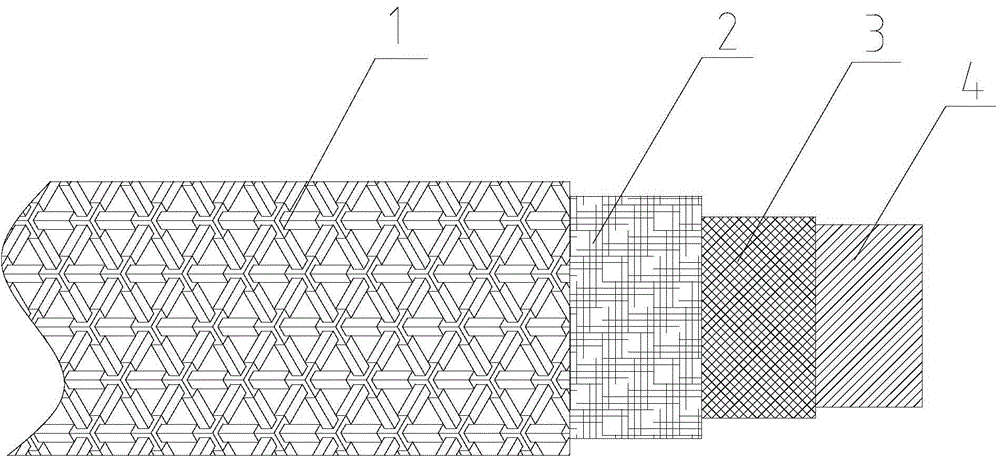

[0020] Heat-resistant and oil-resistant rubber hose, including an outer rubber layer 1, an inner rubber layer 4, and a skeleton layer 3 between them; in terms of mass fraction, the inner rubber layer 4 is composed of the following components: 90 parts of hydrogenated nitrile rubber, 35 parts of semi-reinforcing carbon black, 30 parts of rapid extrusion furnace black, 15 parts of silica, 5 parts of tricresyl phosphate, 1 part of stearic acid, 3 parts of 2,2'-methylene bis-(4-methyl base-6-tert-butylphenol), 1 part of polyethylene glycol 4000, 5 parts of active zinc oxide, 2 parts of accelerator DM, 0.8 parts of vulcanizing agent dicumyl peroxide, 1 part of sulfur, 2 parts of crosslinking aid agent triallyl isocyanurate.

[0021] The heat-resistant and oil-resistant rubber hose also includes a middle rubber layer 2, the middle rubber layer 2 is located between the skeleton layer 3 and the outer rubber layer 1, and the middle rubber layer 2 is composed of the following components...

Embodiment 2

[0023] Heat-resistant and oil-resistant rubber hose, including an outer rubber layer 1, an inner rubber layer 4, and a skeleton layer 3 between them; in terms of mass fraction, the inner rubber layer 4 is composed of the following components: 100 parts of hydrogenated nitrile rubber, 40 parts of semi-reinforcing carbon black, 20 parts of rapid extrusion furnace black, 15 parts of silica, 8 parts of tricresyl phosphate, 1.5 parts of stearic acid, 1 part of 2,2'-methylene bis-(4-methyl base-6-tert-butylphenol), 1.5 parts of polyethylene glycol 4000, 6 parts of active zinc oxide, 0.5 parts of accelerator DM, 0.8 parts of vulcanizing agent dicumyl peroxide, 1 part of sulfur, 2.5 parts of cross-linking aid agent triallyl isocyanurate.

[0024] The heat-resistant and oil-resistant rubber hose also includes a middle rubber layer 2, the middle rubber layer 2 is located between the skeleton layer 3 and the outer rubber layer 1, and the middle rubber layer is composed of the following c...

Embodiment 3

[0026] The heat-resistant and oil-resistant rubber hose includes an outer rubber layer 1, an inner rubber layer 4, and a skeleton layer 3 between them; in terms of mass fraction, the inner rubber layer 4 is composed of the following components: 110 parts of hydrogenated nitrile rubber, 30 parts of semi-reinforcing carbon black, 25 parts of rapid extrusion furnace black, 15 parts of silica, 10 parts of tricresyl phosphate, 0.5 parts of stearic acid, 2 parts of 2,2'-methylene bis-(4-methyl base-6-tert-butylphenol), 2 parts of polyethylene glycol 4000, 4 parts of active zinc oxide, 1 part of accelerator DM, 0.8 parts of vulcanizing agent dicumyl peroxide, 1 part of sulfur, 3 parts of crosslinking aid agent triallyl isocyanurate.

[0027]The heat-resistant and oil-resistant rubber hose also includes a middle rubber layer 2, the middle rubber layer 2 is located between the skeleton layer 3 and the outer rubber layer 1, and the middle rubber layer 2 is composed of the following comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com