Epoxy resin adhesive for bonding fluororubber and metal

A technology of epoxy resin and metal glue, used in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. problem, to achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

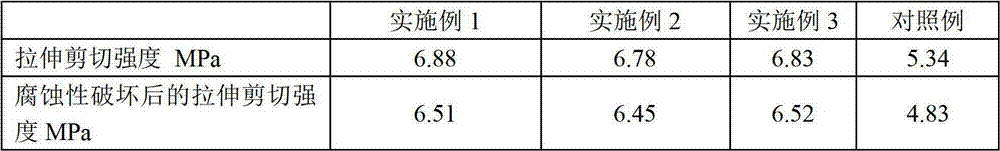

Examples

Embodiment Construction

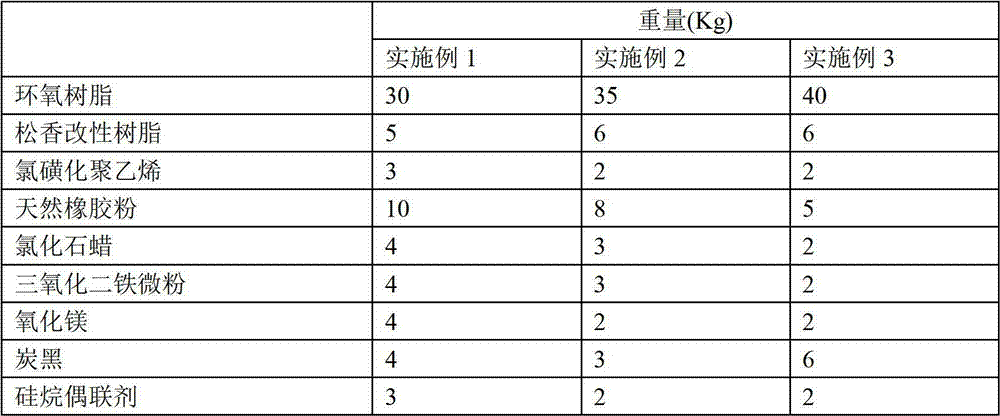

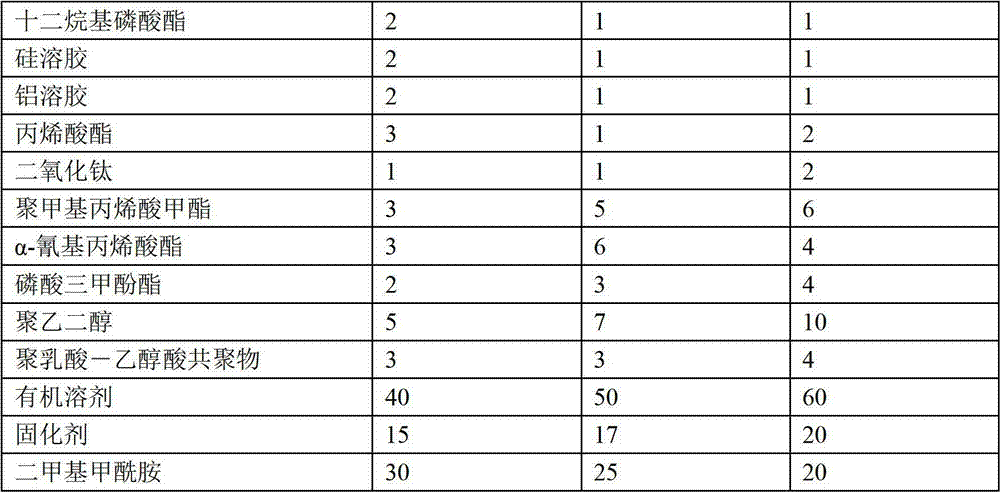

[0018] The components were prepared in the weight ratios shown in Table 1.

[0019] The weight proportion of table 1 embodiment 1~embodiment 3

[0020]

[0021]

[0022] Above-mentioned epoxy resin adopts E-40 epoxy resin.

[0023] The above-mentioned curing agent adopts triethylenetetramine.

[0024] The particle size of the natural rubber powder is 20-200 μm.

[0025] Above-mentioned organic solvent adopts trichloromethane.

[0026] The preparation method is:

[0027] S1: epoxy resin, rosin modified resin, chlorosulfonated polyethylene, natural rubber powder, chlorinated paraffin, ferric oxide micropowder, magnesium oxide, carbon black, silane coupling agent, dodecyl phosphate, Silica sol, aluminum sol, acrylate, titanium dioxide, polymethyl methacrylate, α-cyanoacrylate, tricresyl phosphate, polyethylene glycol, polylactic acid-glycolic acid copolymer are added to the organic solvent and stirred evenly , as component A;

[0028] S2: Dissolve the curing agent in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com