Polyethylene cable insulation material and preparation method thereof

A cable insulation and polyethylene technology, which is applied in the field of polyethylene cable insulation and its preparation, can solve problems affecting product quality and production speed, unstable and disjointed discharge, rough surface, etc., and achieve smooth surface, good fluidity, and production process Ease of operation and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

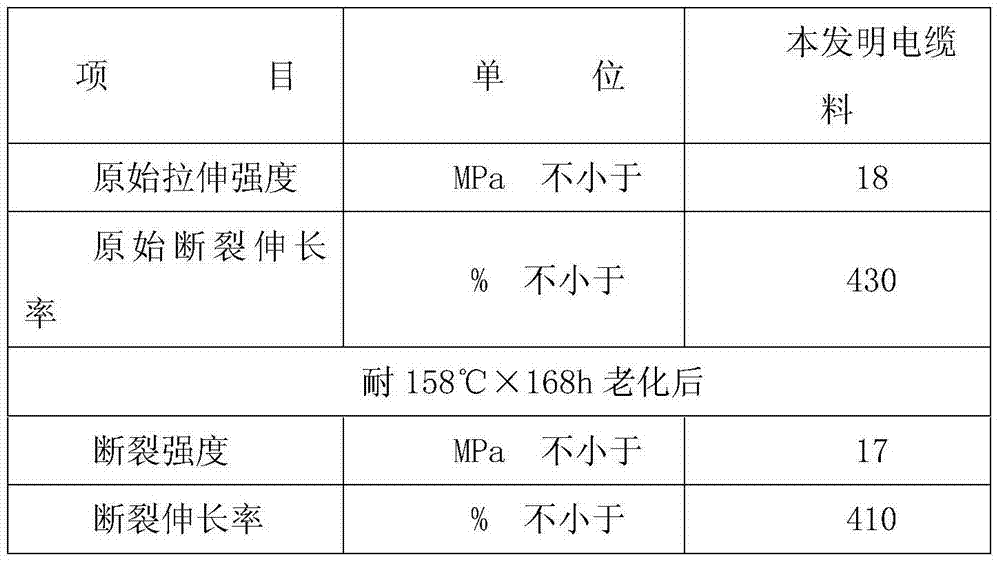

Examples

Embodiment Construction

[0012] The present invention will be described in detail below through specific examples.

[0013] A polyethylene cable insulating material, made of the following raw materials in parts by weight (kg): high-density polyethylene 55, linear low-density polyethylene 13, PE wax 5, diatomite 16, high wear-resistant carbon black N33023, promoting Agent TMTM1, anti-aging agent ODA1, glycerol triglyceride 14, zinc stearate 2, tricresyl phosphate 2, silane coupling agent KH5501, epoxy linseed oil 10, additive 6;

[0014] The auxiliary agent is made of the following raw materials in parts by weight (kg): diatomite 10, tripropylene glycol diacrylate 3, zinc oxide 5, jade powder 4, 3-aminopropyltrimethoxysilane 2, Joint agent TAC2, zinc gluconate 1, zinc stearate 2, magnesium nitrate 9, clove oil 2, rose essential oil 0.1; the preparation method is to send diatomaceous earth into a calciner and calcinate at 700-730°C for 3-4 hours , taken out, soaked in 10-15% hydrochloric acid for 1-2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com