Magnetic liquid sealing device

A technology of sealing device and magnetic liquid, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of increasing the size and weight of sealing structural parts, improve the gradient of magnetic flux density distribution, solve the difficulty of processing and manufacturing, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

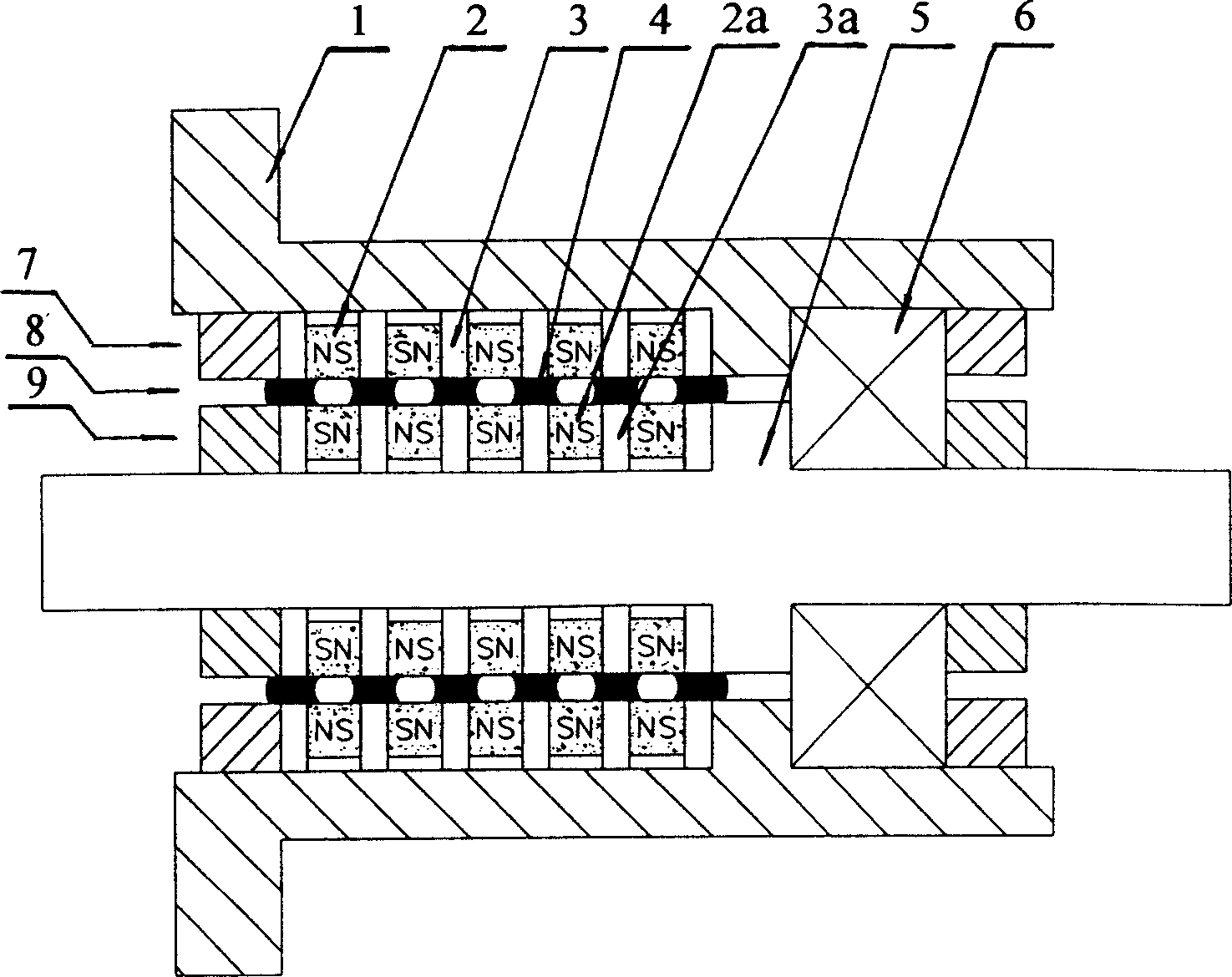

[0027] Example 1 as Figure 1~3 As shown, the dual stacked magnetic pole coils are composed of outer magnetic pole coils 7 and inner magnetic pole coils 9 stacked on the inner and outer sleeves, and are directly installed between coaxial rotating bodies and arranged in alignment with each other. The outer magnetic pole ring 7 and the inner magnetic pole ring 9 of the optimal scheme are respectively composed of 6 to 10 outer and inner pole shoe rings and outer and inner permanent magnetic rings whose number of outer and inner pole shoe rings is minus one. The outer magnetic pole ring 7 of this embodiment 1 is composed of 6 outer pole shoe rings 3 and 5 outer permanent magnetic rings 2 arranged alternately, forming a relationship of ‖N-S‖S-N‖N-S‖S-N‖N-S‖; the inner magnetic pole ring 9 is also composed of Composed of 6 inner pole shoe rings 3a and 5 inner permanent magnet rings 2a arranged alternately, forming the relationship of ‖S-N‖N-S‖S-N‖N-S‖S-N‖, the outer and inner perman...

Embodiment 2

[0028] Example 2 as Figure 4 As shown, it is a set superposition type with a non-magnetic ferrule, the structure is basically the same as that of embodiment 1, the difference is that the outer magnetic pole coil 7 and the inner magnetic pole coil 9 of the dual stack pass through the outer non-magnetic permeable sleeve respectively. The ring 10 and the inner non-magnetic ferrule 10a are hermetically assembled with the relatively rotatable coaxial rotary body, so that it can not only be used for the magnetic liquid seal of the non-magnetic rotary body, but also realize the magnetic liquid seal of the magnetic conductive rotary body .

Embodiment 3

[0029] Example 3 as Figure 5 As shown, its composition is basically the same as that of Example 1, the difference is that the outer and inner pole rings 7 and 9 of the dual stack are respectively provided with outer poles on the sealing gaps 8 of the outer and inner pole rings 3 and 3a Teeth 11 and inner pole teeth 11a to further improve sealing performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com