Method and device for testing magnetic viscosity of magnetic liquid

A magnetic liquid and testing method technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of large number of liquid samples, a large number of liquid samples, and high power consumption, etc., and achieve less sample consumption, convenient use, and high performance The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

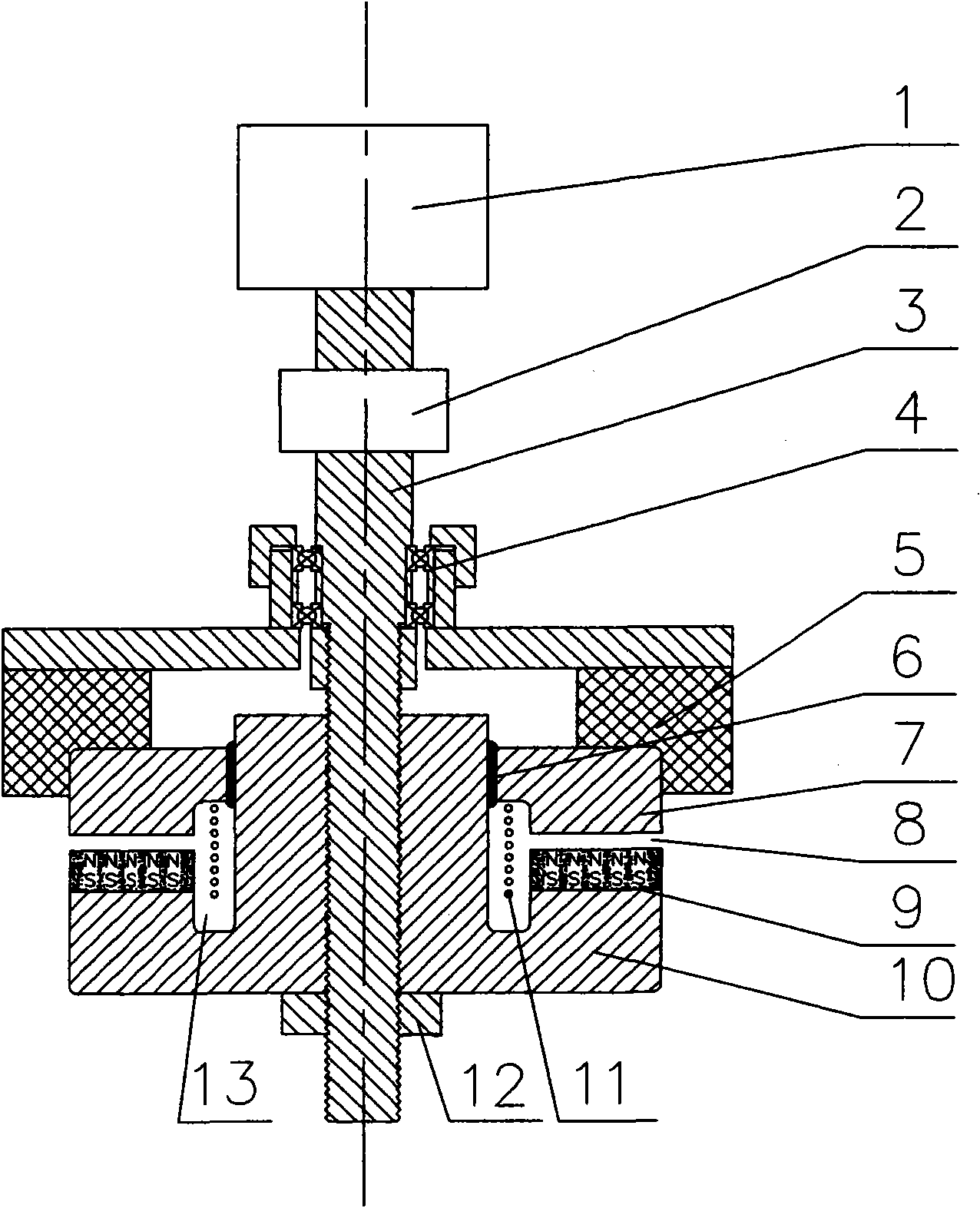

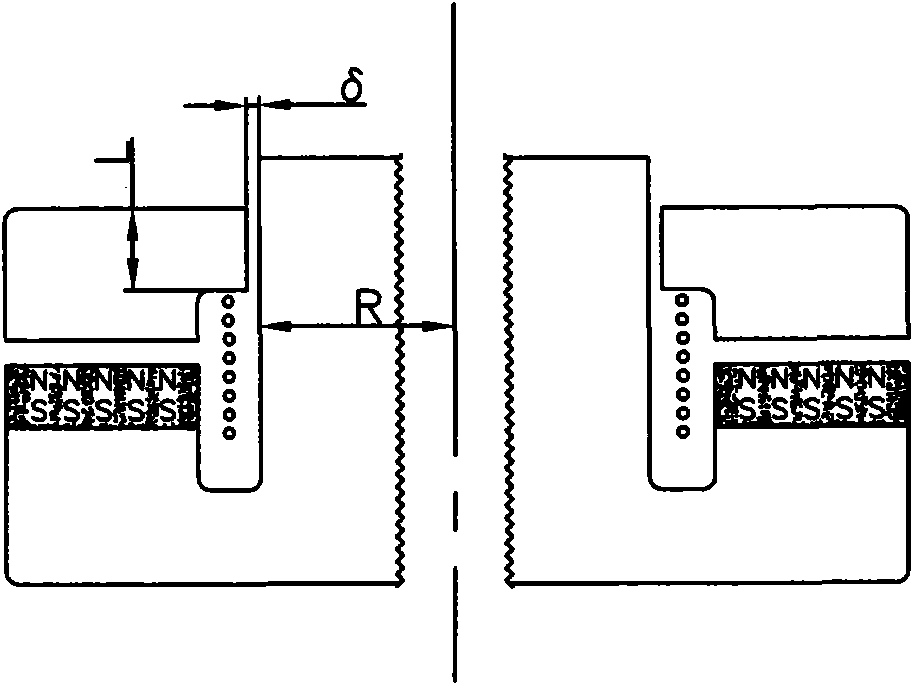

[0054] The concentric connection between the magnetically conductive fixed ring 7 and the rotating shaft 3 through the nonmagnetic centering assembly 5 is that the magnetically conductive fixed ring 7 is fixed in the nonmagnetic centering assembly 5; the described permanent magnet ring 9 is arranged on the magnetically conductive moving ring 10, the radially adjustable gap 8 is formed by the permanent magnet ring 9 and the magnetically permeable fixed ring 7, such as figure 1 shown.

Embodiment 2

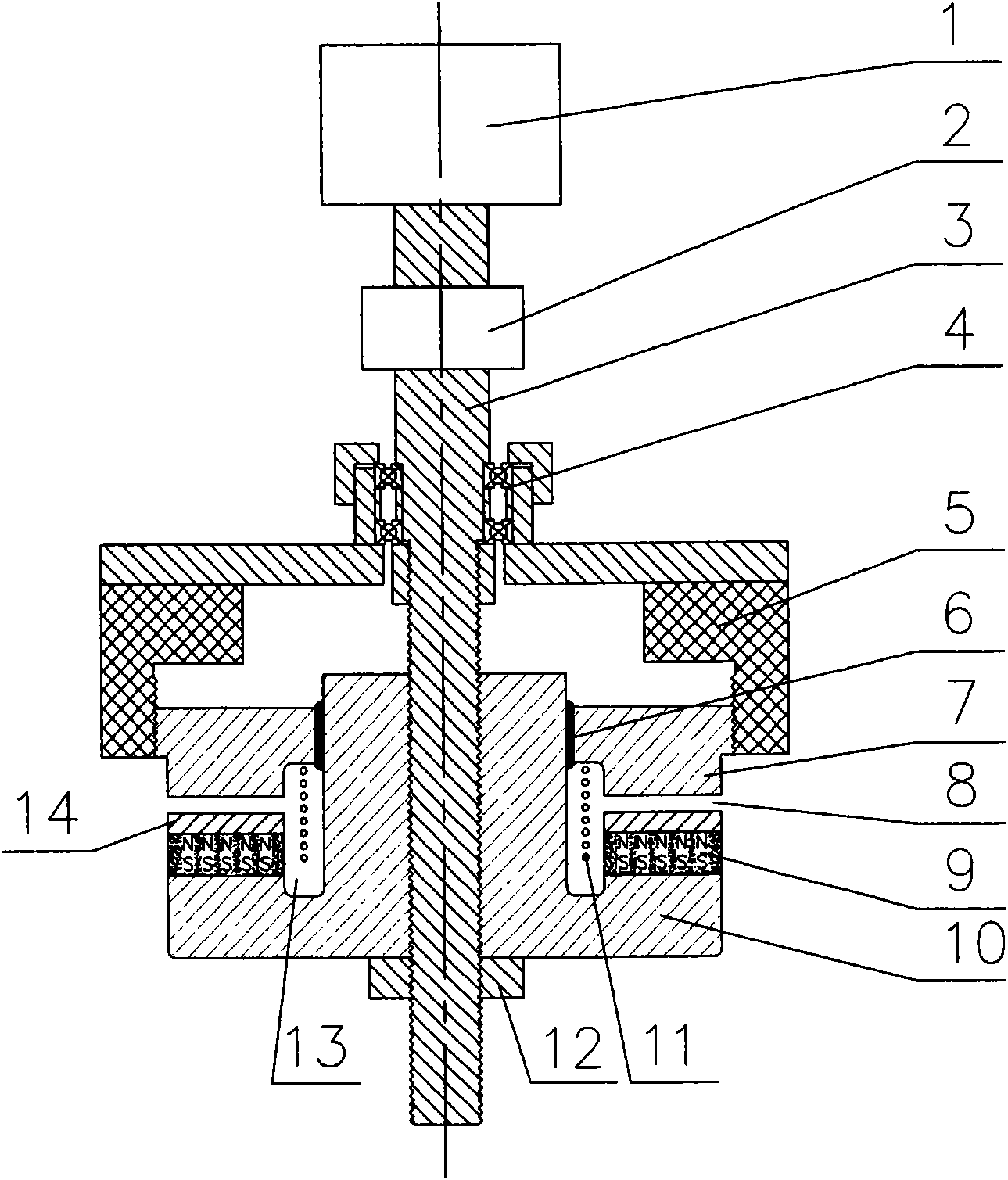

[0056] The concentric connection between the magnetically conductive fixed ring 7 and the rotating shaft 3 through the nonmagnetic centering assembly 5 is that the magnetically conductive fixed ring 7 is threaded in the nonmagnetic centering assembly 5 and can be moved up and down to adjust; adjust the radially adjustable gap 8 size; the permanent magnetic ring 9 is located on the magnetically conductive moving ring 10, and the permanent magnetic ring 9 is provided with a pole shoe ring, 14 which protects the magnetically conductive effect, and the pole shoe ring 14 and the magnetically conductive fixed ring 7 to form a radially adjustable gap 8, such as image 3 shown.

Embodiment 3

[0058] The concentric connection between the magnetically conductive fixed ring 7 and the rotating shaft 3 through the non-magnetic centering assembly 5 is the same as that of embodiment 1, and the magnetically conductive fixed ring 7 is also fixed in the nonmagnetic centering assembly 5; the permanent magnetic ring 9 is located below the magnetically conductive fixed ring 7, and the radially adjustable gap 8 is formed by the permanent magnetic ring 9 and the magnetically conductive moving ring 10, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com