Magnetic-liquid micro differential pressure sensor

A micro differential pressure sensor, magnetic liquid technology, applied in the direction of measuring fluid pressure, pressure difference measurement between multiple valves, instruments, etc., can solve the problems of high cost, weak sensor signal, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described with accompanying drawing as specific embodiment:

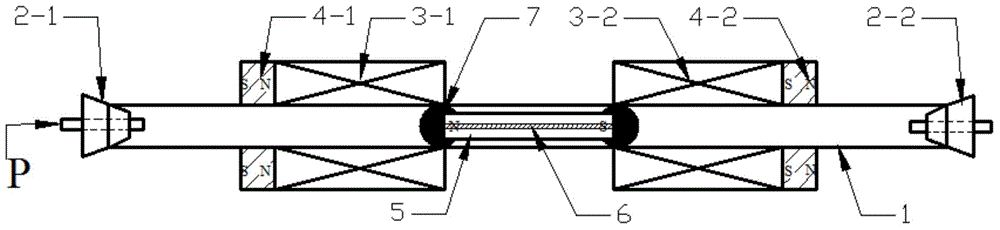

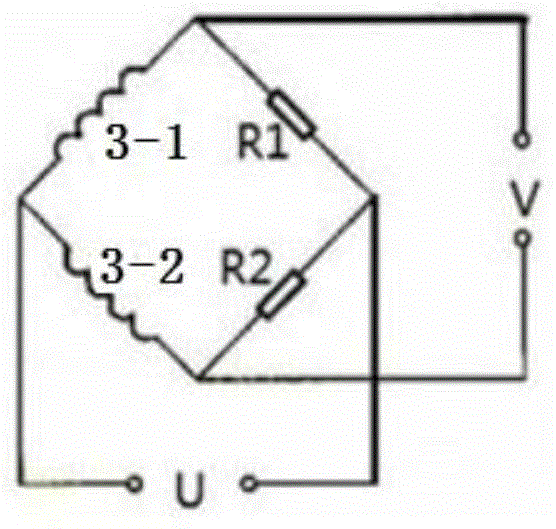

[0016] A magnetic liquid micro pressure difference sensor, the device includes: plexiglass tube 1, left rubber plug 2-1, right rubber plug 2-2, left coil 3-1, right coil 3-2, left ring magnet 4-1 , right ring magnet 4-2, hollow permanent magnet 5, iron core 6, magnetic liquid 7, first fixed value resistor R1, second fixed value resistor R2, AC power supply U and voltmeter V.

[0017] First, the high-strength enamelled copper wire is uniformly, equal number of turns, and symmetrically wound on the left and right sides of the plexiglass tube 1 to form a left coil 3-1 and a right coil 3-2, and the distance between the two coils is equal to the length of the hollow permanent magnet 5; Then the iron core 6 is inserted in the hollow permanent magnet 5, the iron core 6 is equal to the length of the hollow permanent magnet 5, and the two form a composite magnetic core together; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com