Water-based magnetic liquid and method for making same

A magnetic liquid, water-based technology, applied in the fields of magnetic liquid, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low efficiency and weak magnetic properties of water-based magnetic liquid, and achieve good economic and social benefits, The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

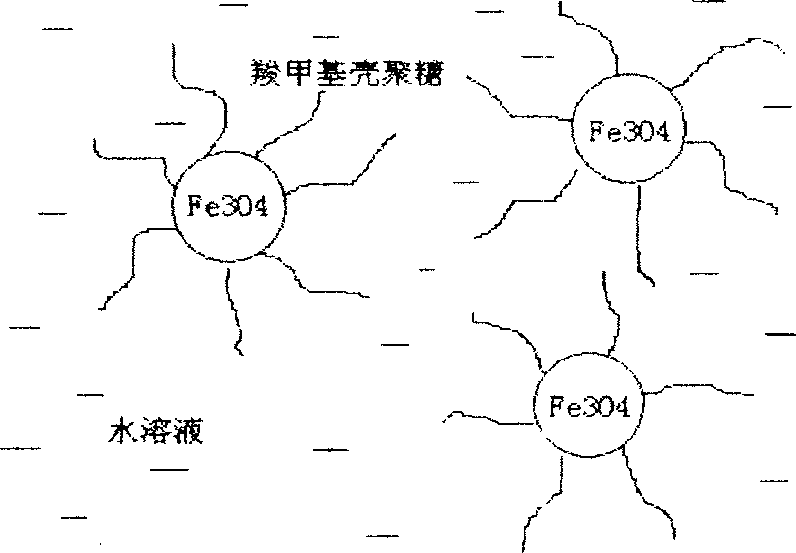

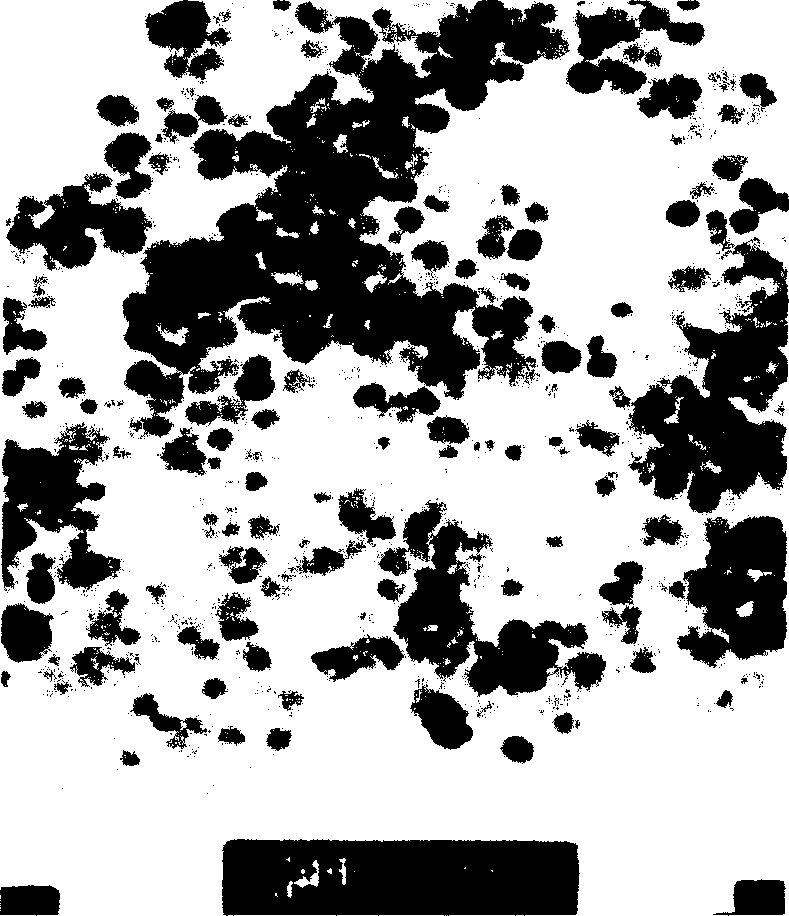

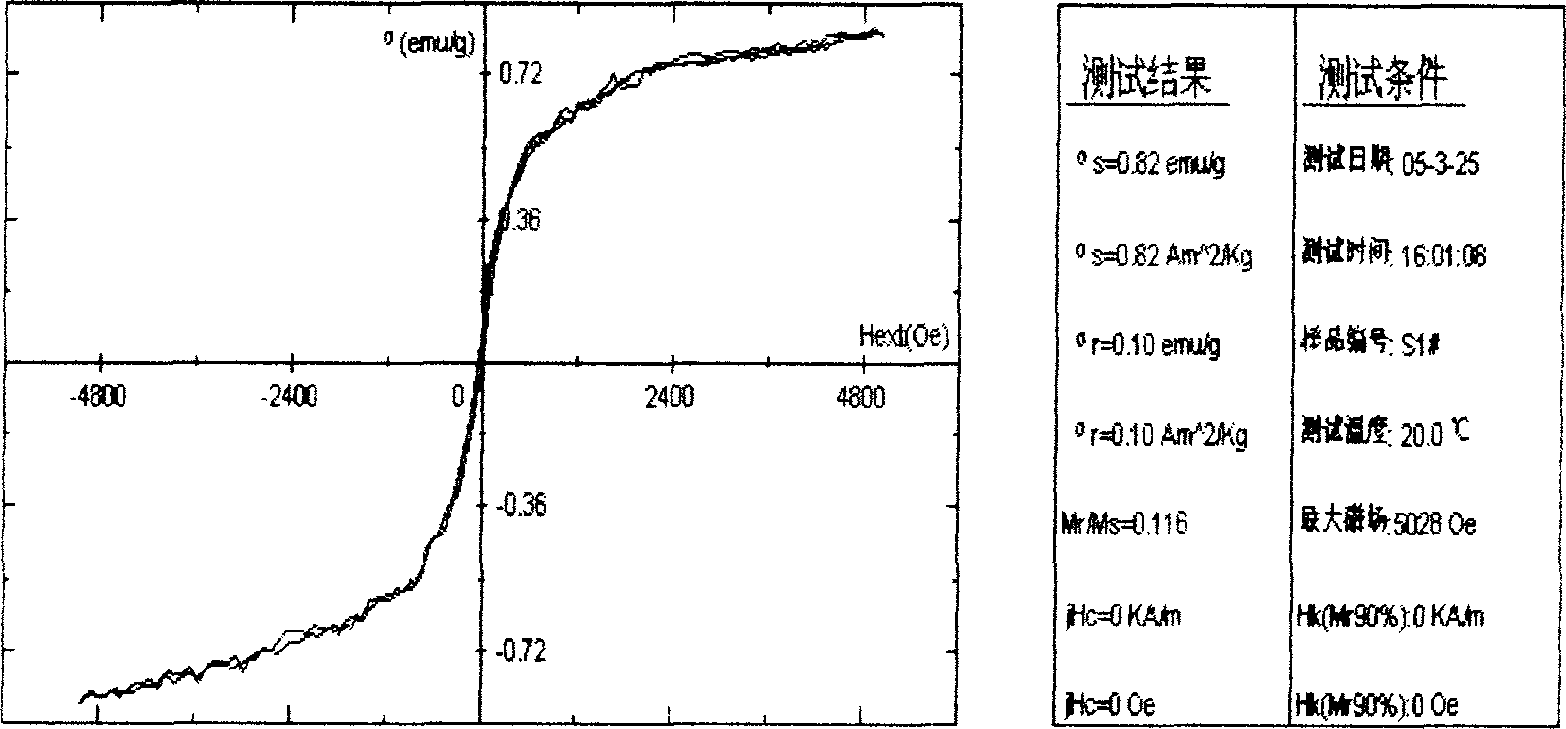

Embodiment 1

[0026] FeCl 3 ·6H 2 O is made into an aqueous solution with a mass concentration of 66.6%, and FeSO 4 ·7H 2 O is formulated into 21.9% aqueous solution, press Fe 2+ : Fe 3+ =1:1.5~2 Mix the two solutions to form a mixed solution of iron salt. The mass ratio of carboxymethyl chitosan to 25% ammonia water is within the range to form a solution, carboxymethyl chitosan and 25% The mass ratio of ammonia water is 1:5. Stir the carboxymethyl chitosan in ammonia water at a high speed under the condition of about 90℃ in a water bath while injecting Fe 2+ , Fe 3+ Mixture, control carboxymethyl chitosan and Fe after synthesis 3 O 4The quality is 1:1, the reaction time is controlled at about 30 minutes, the stirring speed at the initial stage of the reaction is 1200 revolutions / minute, and the stirring speed at the end of the reaction is 650 revolutions / minute. After the reaction, the magnetic liquid is taken out and centrifuged to separate unstable particles to obtain a stable magnetic liqui...

Embodiment 2

[0028] FeCl 3 ·6H 2 O is made into an aqueous solution with a mass concentration of 66.6%, and FeSO 4 ·7H 2 O is formulated into 21.9% aqueous solution, press Fe 2+ : Fe 3+ =1:1.5~2 Mix the two solutions to form a mixed solution of iron salt. The mass ratio of carboxymethyl chitosan to 25% ammonia water is within the range to form a solution, carboxymethyl chitosan and 25% The mass ratio of ammonia water is 1:10. Stir the carboxymethyl chitosan in ammonia water at a high speed under the condition of about 90℃ in a water bath while injecting Fe 2+ , Fe 3+ Mixture, control carboxymethyl chitosan and Fe after synthesis 3 O 4 The quality is 2:1, and the reaction is carried out under nitrogen protection, and the reaction time is controlled at more than 2 hours. The stirring speed at the initial stage of the reaction is 1200 revolutions / minute, and the stirring speed at the latter stage of the reaction is 650 revolutions / minute. After the reaction, the magnetic liquid is taken out and c...

Embodiment 3

[0030] FeCl 3 ·6H 2 O is made into an aqueous solution with a mass concentration of 66.6%, and FeSO 4 ·7H 2 O is formulated into 21.9% aqueous solution, press Fe 2+ : Fe 3+ =1:1.5~2 Mix the two solutions to form a mixed solution of iron salt. The mass ratio of carboxymethyl chitosan to 25% ammonia water is within the range to form a solution, carboxymethyl chitosan and 25% The mass ratio of ammonia water is 1:15. Stir the carboxymethyl chitosan in ammonia water at a high speed under the condition of about 90℃ in a water bath while injecting Fe 2+ , Fe 3+ Mixture, control carboxymethyl chitosan and Fe after synthesis 3 O 4 The quality is 3:1, and the reaction is carried out under nitrogen protection and ultrasonic conditions, and the reaction time is controlled at more than 2 hours. The stirring speed at the initial stage of the reaction is 1000 revolutions per minute, and the stirring speed at the latter stage of the reaction is 800 revolutions per minute. After the reaction, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com