Magnetic fluid damping device

A technology of magnetic liquid and vibration damping device, applied in the direction of magnetic spring, spring/shock absorber, spring, etc., can solve the problem that the vibration damping method is difficult to meet the requirements, and achieve the effect of small acceleration, small displacement and low frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

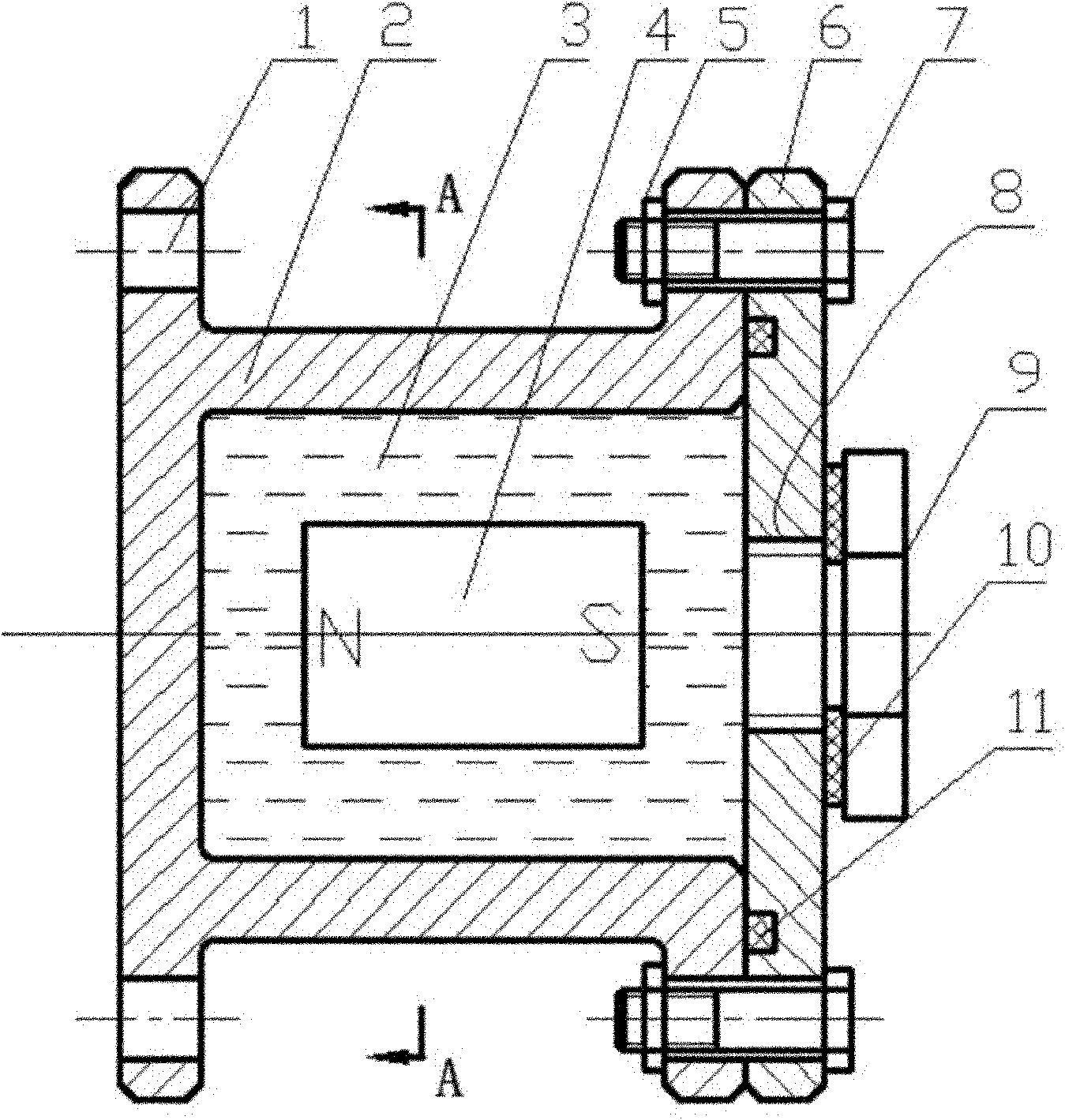

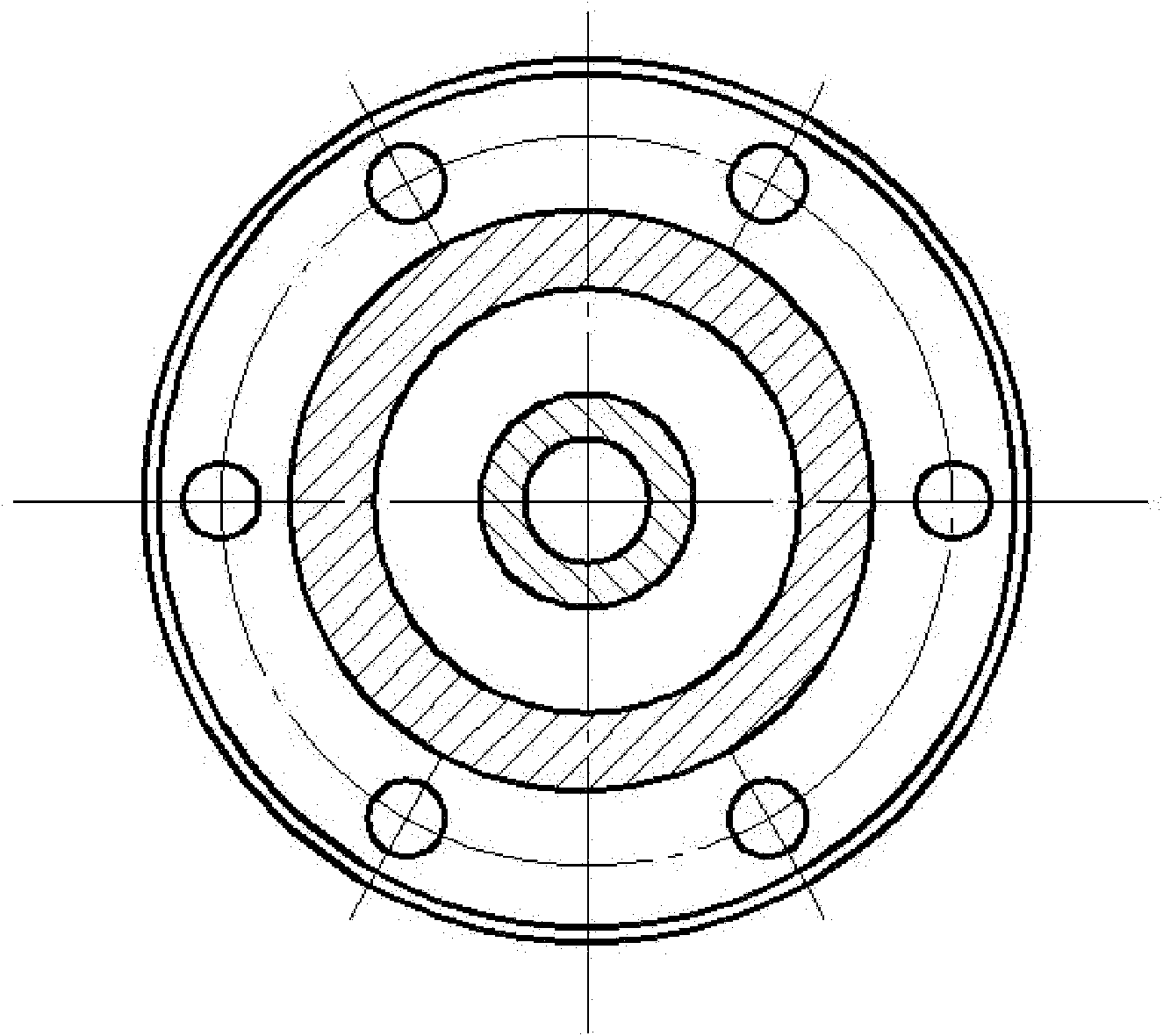

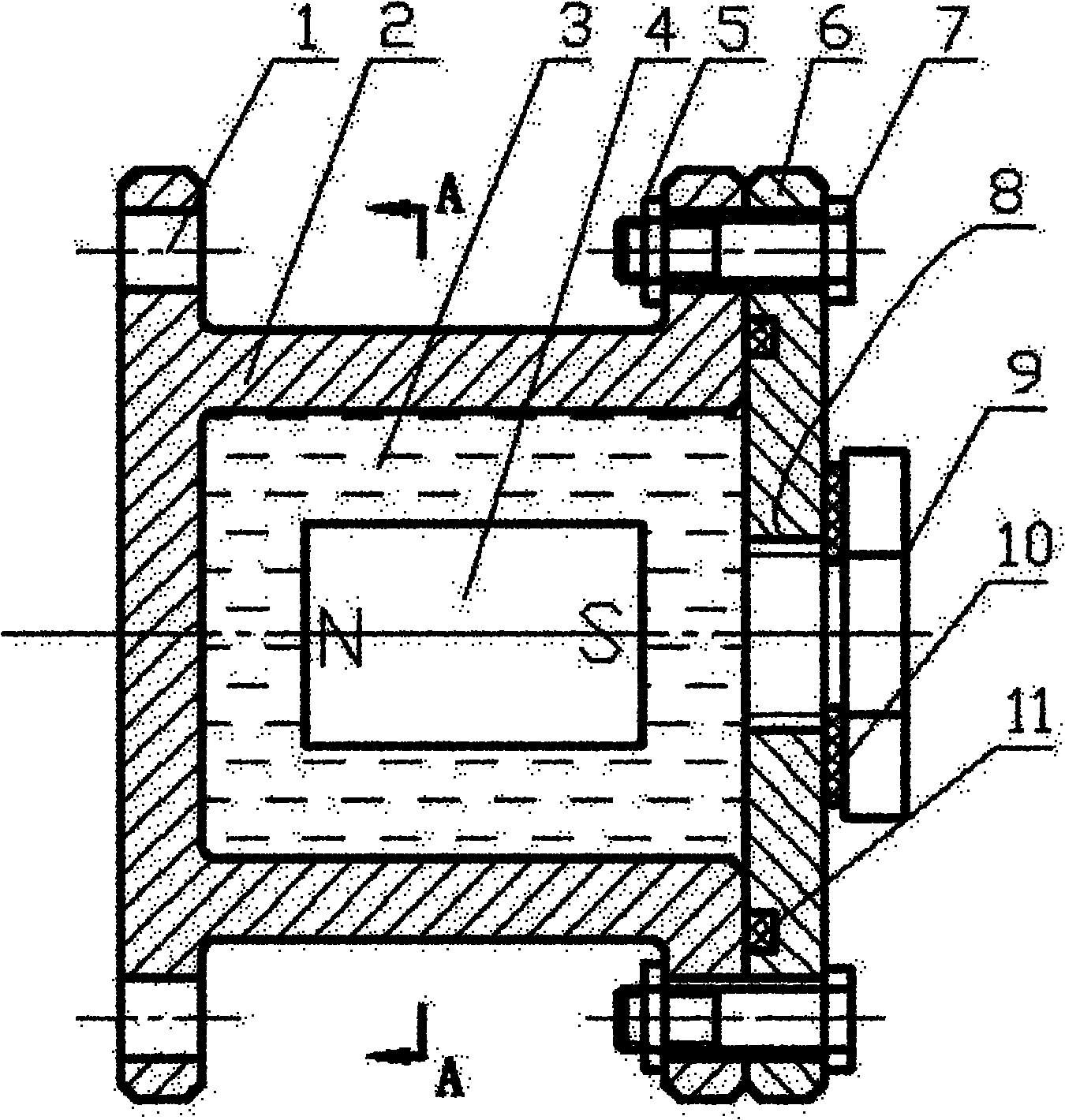

[0021] A magnetic liquid damping device, which is composed of a non-magnetic shell 2, a magnetic liquid 3, a permanent magnet 4, a nut 5, an end cover 6, a bolt 7, a screw 9, a gasket 10 and an O-ring 11.

[0022] Connections between the above parts:

[0023] Put the permanent magnet 4 into the cavity of the non-magnetic shell 2, and fix the end cover 6 with the O-ring 11 on one end of the non-magnetic shell 2 with the bolt 7 and the nut 5;

[0024] Fill the cavity of the non-magnetic shell 2 with magnetic liquid 3 through the threaded hole 8, and seal it with screws 9 and gaskets 10.

[0025] The shape of the permanent magnet 4 is a round tube, and its size parameters are: the ratio of the outer diameter of the round tube to the inner diameter of the non-magnetic shell 2 cavity is 0.5, the thickness of the round tube is 0.20mm, and the length is equal to the inner diameter of the non-magnetic shell 2. The length ratio is 0.25.

[0026] The magnetic liquid 3 is a diester-bas...

Embodiment approach 2

[0028] The difference between Embodiment 2 and Embodiment 1 is that the ratio of the outer diameter of the round tube to the inner diameter of the cavity of the non-magnetic shell 2 is 0.75, the thickness of the round tube is 0.35 mm, and the ratio of the length to the length of the non-magnetic shell 2 is 0.75.

[0029] The magnetic liquid 3 is water-based magnetic liquid.

Embodiment approach 3

[0031] The difference between Embodiment 3 and Embodiment 1 is that the ratio of the outer diameter of the round tube to the inner diameter of the cavity of the non-magnetic shell 2 is 0.6, the thickness of the round tube is 0.25 mm, and the ratio of the length to the length of the non-magnetic shell 2 is 0.5.

[0032] The magnetic liquid 3 is an oil-based magnetic liquid or a kerosene-based magnetic liquid.

[0033] The through hole 1 is designed for connection to the device to be damped.

[0034] The threaded hole 8 is designed to facilitate the injection of magnetic liquid.

[0035] The material of the screw 9, the non-magnetic shell 2 and the end cover 6 is 1Cr18Ni9Ti.

[0036] The permanent magnet 4 is made of NdFeB material.

[0037] The invention is suitable for local vibration reduction of many longer objects (such as solar sails, satellite antennas, etc.) in space vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com