Anti-glare film with high wear resistance and low flash point

An anti-glare film and anti-glare technology, applied in optics, optical components, instruments, etc., can solve the problems of wear resistance and flash point, the lack of essential improvement in wear resistance, poor wear resistance of anti-glare film, etc. problems, to achieve the effect of being conducive to stress absorption, improving the overall hardness, and good flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

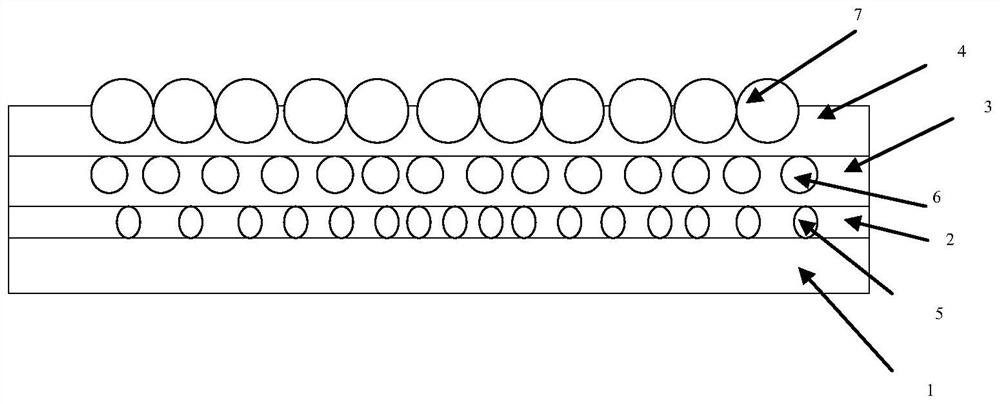

[0047] In the present invention, the preparation method of the anti-glare film comprises the following steps:

[0048] (1) Mix the raw materials of the anti-glare coating solution according to the proportion, and stir evenly to obtain coating solution 1, coating solution 2 and coating solution 3.

[0049] (2) Coating the first coating solution, the second coating solution and the third coating solution on the substrate in sequence, and then using ultraviolet light to obtain the anti-glare film.

[0050] The preferred solution in the present invention is that when preparing the coating solution, firstly add the acrylate prepolymer and acrylate monomer to the solvent, stir and dissolve at a high speed, then add the photoinitiator, anti-glare particles and leveling agent , dispersant, fluorine-containing additives, fully stirred evenly.

[0051] The preferred solution in the present invention is that, when coating, the surface of the coating is dried by heating and baking every ...

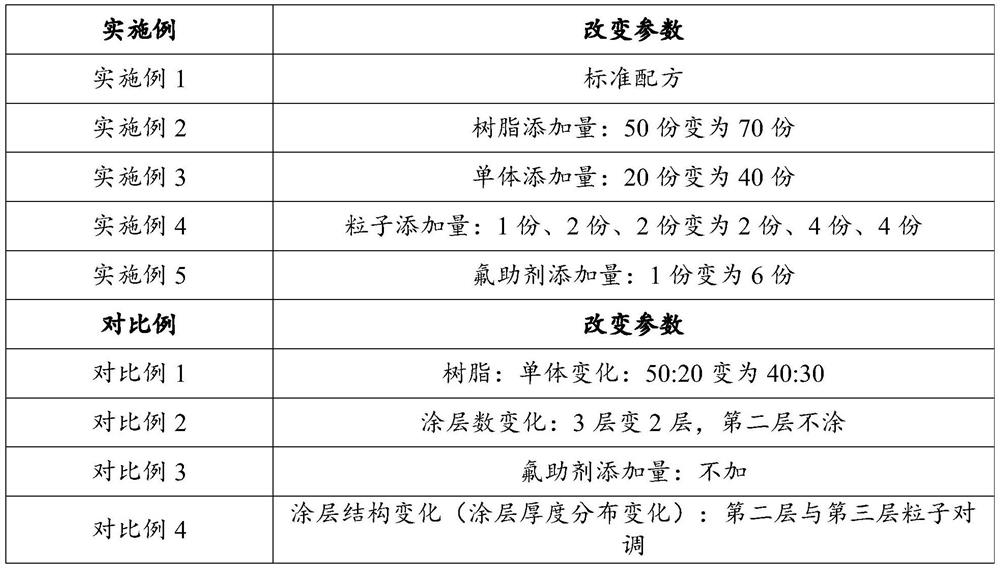

Embodiment 1

[0054] 1. Preparation of coating solution

[0055] Add 40 parts of hexafunctional urethane acrylic resin oligomer CN9010NS (manufactured by Sartomer, refractive index 1.49) and 20 parts of pentafunctional acrylate monomer SR399NS (manufactured by Sartomer, refractive index 1.49) in 200 parts of propylene glycol methyl ether ), after high-speed stirring and dissolving, add 4 parts of photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 1 part of photoinitiator TPO (manufactured by Tianjin Tianjiao Chemical Co., Ltd.), then add 1 part of antiglare particle PMMA particle MX- 80H3WT (Nippon Soken Chemical, particle size 0.7μm, refractive index 1.48), then add 1 part of leveling agent BYK-333 (Byke Chemicals), 1 part of dispersant DISPERBYK-110 (Byke Chemicals), fully stir evenly, Obtain coating solution 1;

[0056] Add 50 parts of hexafunctional urethane acrylic resin oligomer CN9010NS (manufactured by Sartomer, refractive index 1.49) and 20 parts of penta...

Embodiment 2

[0061] 1. Preparation of coating solution

[0062] Add 70 parts of hexafunctional urethane acrylic resin oligomer CN9010NS (manufactured by Sartomer, refractive index 1.49) and 20 parts of pentafunctional acrylate monomer SR399NS (manufactured by Sartomer, refractive index 1.49) in 200 parts of propylene glycol methyl ether ), after high-speed stirring and dissolving, add 4 parts of photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 1 part of photoinitiator TPO (manufactured by Tianjin Tianjiao Chemical Co., Ltd.), then add 1 part of antiglare particle PMMA particle MX- 80H3WT (Nippon Soken Chemical, particle size 0.7μm, refractive index 1.48), then add 1 part of leveling agent BYK-333 (Byke Chemicals), 1 part of dispersant DISPERBYK-110 (Byke Chemicals), fully stir evenly, Obtain coating solution 1;

[0063] Add 70 parts of hexafunctional urethane acrylic resin oligomer CN9010NS (manufactured by Sartomer, refractive index 1.49) and 20 parts of penta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com