Fischer-Tropsch synthesis liquid wax environment-friendly biofuel and preparation process thereof

A technology of biofuel and Fischer-Tropsch synthesis, which is applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of not being able to store for a long time, short shelf life, and high corrosion, and achieve good oxidation resistance and corrosion resistance Non-toxic, corrosive, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

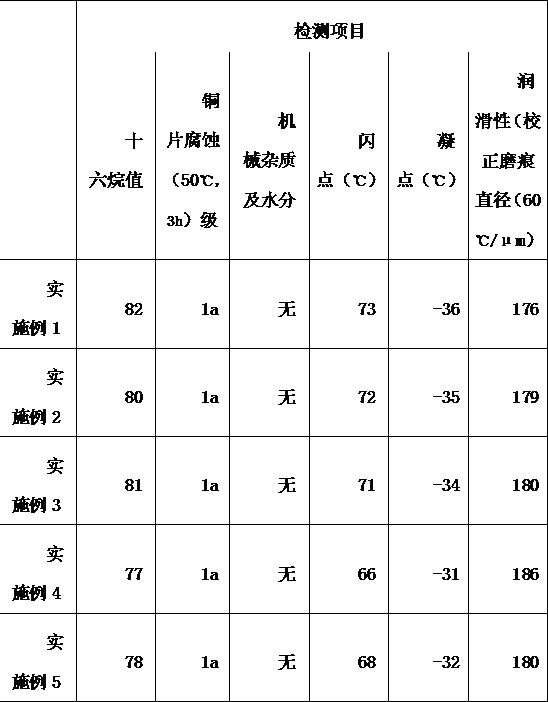

Examples

Embodiment 1

[0041] The Fischer-Tropsch synthetic liquid wax environment-friendly biofuel of the present embodiment, by weight percentage, comprises the following components:

[0042] Industrial white oil 66%;

[0043] Biodiesel 4%;

[0044] Fischer-Tropsch synthetic liquid wax 26.5%;

[0045] Additive 3.5%.

[0046] Wherein, the industrial white oil is C 16 -C 23 mixture of alkanes.

[0047] Wherein, the biodiesel is obtained through esterification of palm oil and alcohol.

[0048] Wherein, the additives include emulsifiers, stabilizers, cosolvents, pour point depressants, combustion aids and dispersants.

[0049] Wherein, the mass content of the emulsifier in the biofuel is 0.3%; the mass content of the stabilizer in the biofuel is 0.5%; the mass content of the co-solvent in the biofuel is 1.0%; the mass content of the pour point depressant in the biofuel is 0.5%; the mass content of the combustion aid in the biofuel is 0.2%; the mass content of the dispersant in the biofuel The ...

Embodiment 2

[0063] The Fischer-Tropsch synthetic liquid wax environment-friendly biofuel of the present embodiment, by weight percentage, comprises the following components:

[0064] 70% industrial white oil;

[0065] Biodiesel 4%;

[0066] Fischer-Tropsch synthetic liquid wax 22%;

[0067] Additive 4%.

[0068] Wherein, the industrial white oil is C 16 -C 23 mixture of alkanes.

[0069] Wherein, the biodiesel is obtained through esterification reaction of corn oil and alcohol.

[0070] Wherein, the additives include emulsifiers, stabilizers, cosolvents, pour point depressants, combustion aids and dispersants.

[0071] Wherein, the mass content of the emulsifier in the biofuel is 0.5%; the mass content of the stabilizer in the biofuel is 0.5%; the mass content of the co-solvent in the biofuel is 1.3%; the mass content of the pour point depressant in the biofuel is 0.5%; the mass content of the combustion aid in the biofuel is 0.2%; the mass content of the dispersant in the biofuel ...

Embodiment 3

[0085] The Fischer-Tropsch synthetic liquid wax environment-friendly biofuel of the present embodiment, by weight percentage, comprises the following components:

[0086] Industrial white oil 64%;

[0087] Biodiesel 5%;

[0088] Fischer-Tropsch synthetic liquid wax 28%;

[0089] Additive 3%.

[0090] Wherein, the industrial white oil is C 16 -C 23 mixture of alkanes.

[0091] Wherein, the biodiesel is obtained through esterification reaction of rapeseed oil and alcohol.

[0092] Wherein, the additives include emulsifiers, stabilizers, cosolvents, pour point depressants, combustion aids and dispersants.

[0093] Wherein, the mass content of the emulsifier in the biofuel is 0.3%; the mass content of the stabilizer in the biofuel is 0.4%; the mass content of the co-solvent in the biofuel is 0.5%; the mass content of the pour point depressant in the biofuel is 0.5%; the mass content of the combustion aid in the biofuel is 0.3%; the mass content of the dispersant in the biof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com