Preparation method of water-alcohol mixed base micro-emulsified diesel oil

A mixed-base, micro-emulsion technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of inability to realize large-scale industrial production, expensive surfactants, and high cost of micro-emulsions, and achieve the elimination of icing phenomenon , the appearance is clear and transparent, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

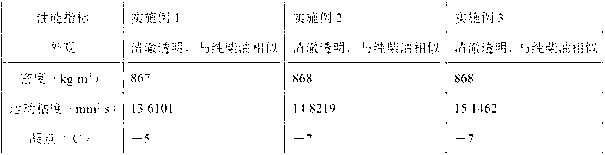

Embodiment 1

[0023] (1) Add 2g of oleic acid to 30g of diesel oil, stir to dissolve it, then add 0.5g of stearic acid, and stir rapidly (at a speed of 300 rpm) until the stearic acid is completely dissolved to form solution A;

[0024] (2) Add isooctyl alcohol, isobutanol, ethyl acetate, and triethanolamine (both 0.5g) to 10g of methanol in sequence (make sure that the previous additive is completely dissolved before adding the next raw material ), stirring and dissolving to obtain solution B; under rapid stirring, solution B was added to solution A, and then stirred rapidly for 80 minutes to obtain clear and transparent microemulsion C;

[0025] (3) Weigh 0.1g of sodium hydroxide, dissolve it in 10g of tap water, add 2g of oleic acid, stir and react at room temperature for 1~2min; after the reaction is complete, add it to microemulsion C, and stir rapidly for 100min to form a milky Liquid D;

[0026] (4) Add 1.1g of surfactants (Span-80 1g, Tween-80 0.1g) into emulsion D, and continue to...

Embodiment 2

[0029] (1) Add 2.5g of oleic acid to 30g of diesel oil, stir to dissolve it, then add 0.5g of stearic acid, and stir rapidly (at a speed of 300 rpm) until the stearic acid is completely dissolved to form solution A;

[0030] (2) Add 0.5g of isooctyl alcohol, 0.5g of isobutanol, 1.0g of ethyl acetate, and 0.5g of triethanolamine to 10g of methanol in sequence (before adding the next raw material, it must be ensured that the previous additive has been Completely dissolve), stir and dissolve to obtain solution B; add solution B to solution A under rapid stirring, and then stir rapidly for 80 minutes to obtain clear and transparent microemulsion C;

[0031] (3) Weigh 0.1g of sodium hydroxide, dissolve it in 10g of tap water, add 2g of oleic acid, stir and react at room temperature for 1~2min; after the reaction is complete, add it to microemulsion C, and stir rapidly for 100min to form a milky Liquid D;

[0032] (4) Add 1.1g of surfactants (Span-80 1g, Tween-80 0.1g) into emulsio...

Embodiment 3

[0035] (1) Add 3g of oleic acid to 30g of diesel oil, stir to dissolve it, then add 0.5g of stearic acid, and stir rapidly (at a speed of 300 rpm) until the stearic acid is completely dissolved to form solution A;

[0036] (2) Add isooctyl alcohol, isobutanol, ethyl acetate, and triethanolamine (both 0.5g) into 10g of methanol in sequence (make sure that the previous additive is completely dissolved before adding the next raw material ), stirring and dissolving to obtain solution B; under rapid stirring, solution B was added to solution A, and then stirred rapidly for 80 minutes to obtain clear and transparent microemulsion C;

[0037] (3) Weigh 0.1g of sodium hydroxide, dissolve it in 10g of tap water, then add 2g of oleic acid, stir and react at room temperature for 1~2min; after the reaction is complete, add it to microemulsion C, and stir rapidly for 100min to form a milky Liquid D;

[0038] (4) Add 2.2g of surfactants (Span-80 2.0g, Tween-80 0.2g) into emulsion D, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com