Lubricating oil base oil composition

A lubricating oil base oil and composition technology, which is applied in the direction of lubricating composition, base material, petroleum industry, etc., can solve the problems that cannot meet the requirements of lubricating oil viscosity index and volatility specifications, and achieve the effect of increasing value and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

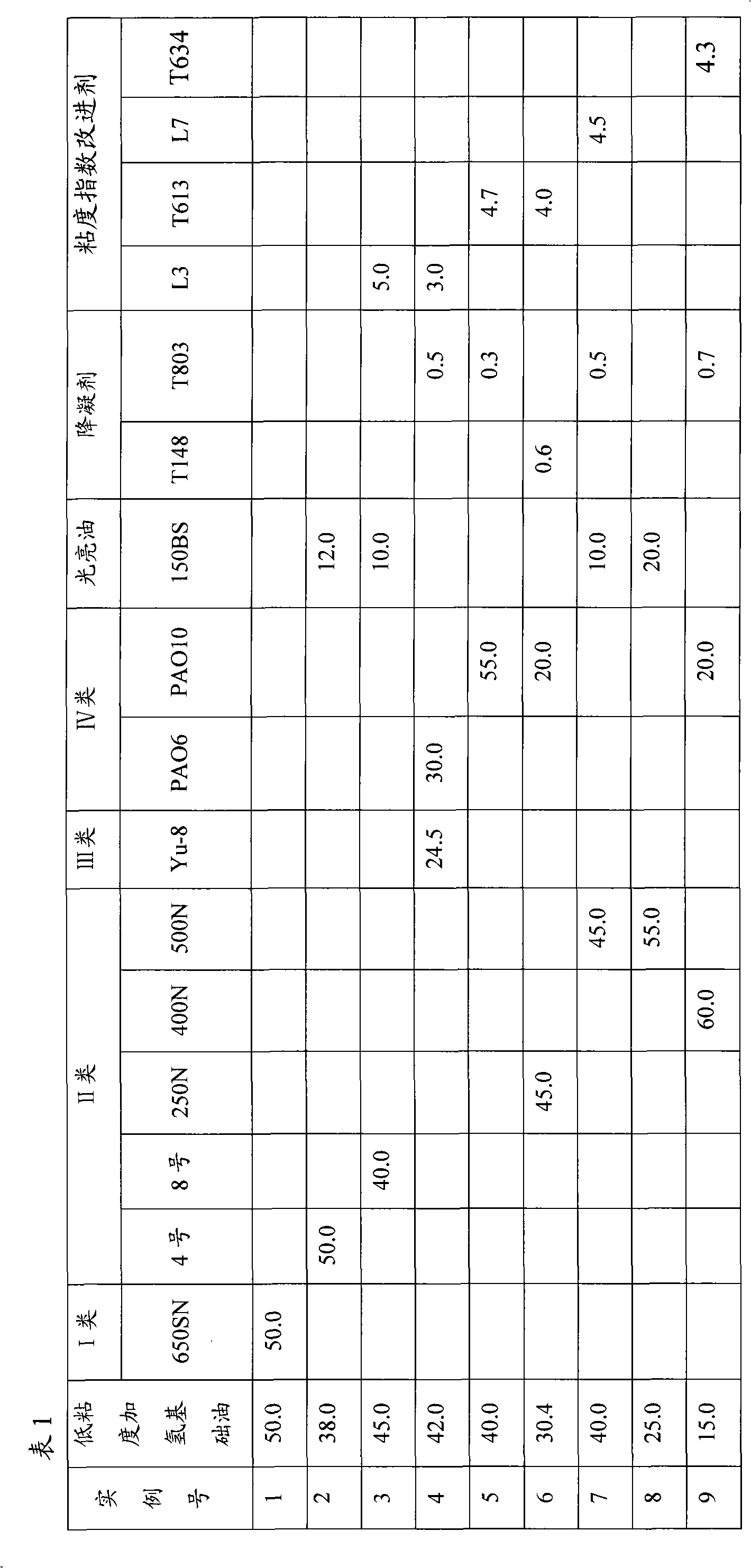

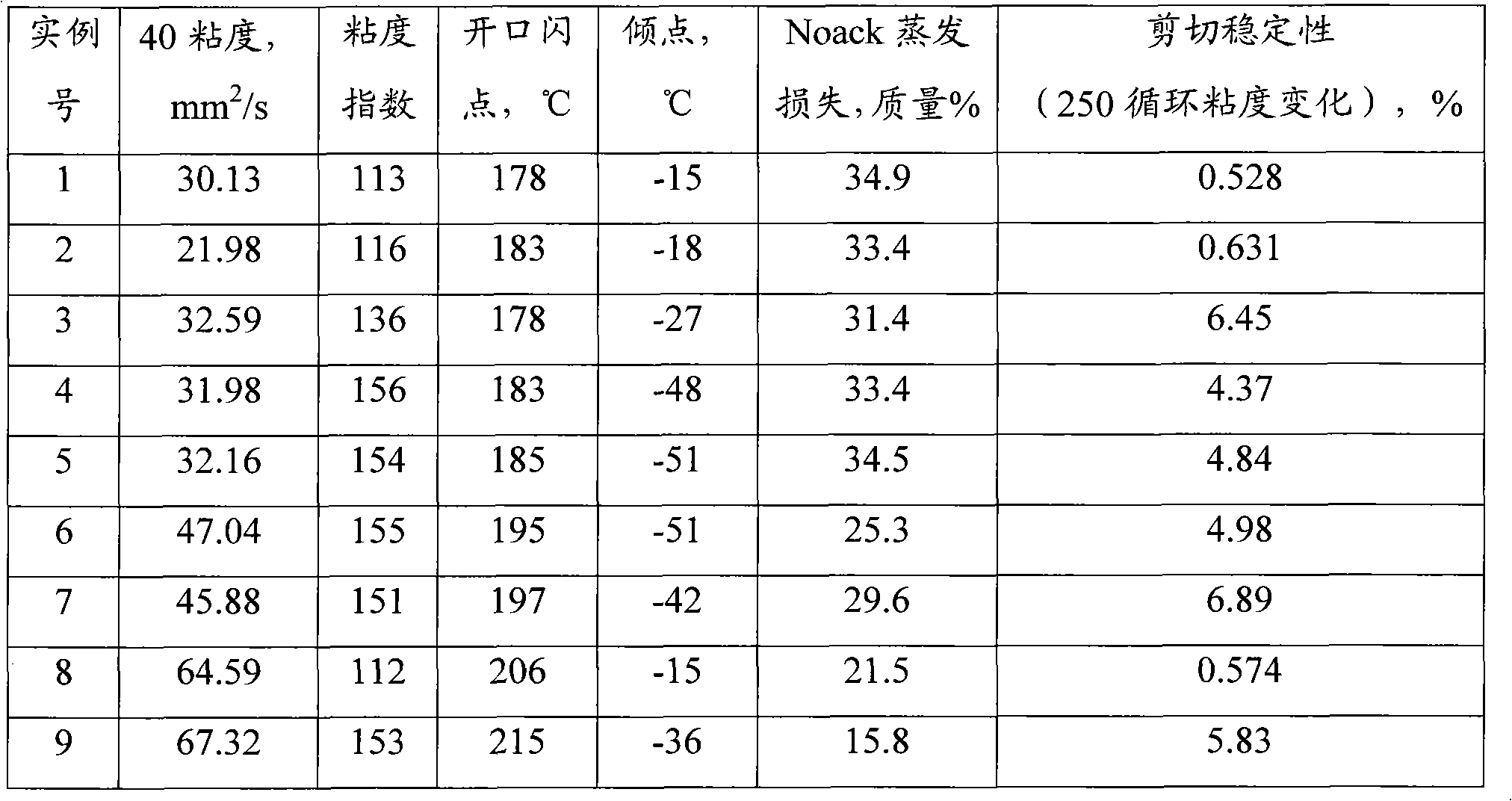

[0030]Take equal quality low viscosity hydrogenated base oil and Group I base oil 650SN. First add 650SN into a blending kettle with a stirring device, then add low-viscosity hydrogenated base oil, stir at 25°C for 40 minutes, and filter to obtain a blended base oil composition. The mass percentage of each component is shown in Table 1. The physical and chemical properties are shown in Table 2. Among them, the determination method of shear stability is SH / T0103, and the determination method of Noack evaporation mass loss is SH / T0731.

[0031] The 100°C viscosity of the low viscosity hydrogenated base oil used is 2.535mm 2 / s, viscosity at 40°C is 9.73mm 2 / s, viscosity index 81, pour point -45°C, open flash point 165°C, Noack evaporation mass loss (250°C, 1h) 79.5%, paraffin content in composition 37.60 mass%, total naphthene content 62.35 mass%, aromatics The sulfur content is 0.03% by mass, and the sulfur content is 0.02% by mass.

[0032] The 100°C viscosity of 650SN ba...

example 2

[0034] Take low-viscosity hydrogenated base oil, No. 4 hydrogenated base oil and bright stock 150BS and prepare them according to the mass ratio of 38:50:12. First add No. 4 hydrogenated base oil and 150BS into the blending kettle with stirring device, then add low-viscosity hydrogenated base oil, stir for 60 minutes at 20°C, and filter to obtain the blended base oil composition. The mass of each component The percentage content is shown in Table 1, and the physical and chemical properties are shown in Table 2.

[0035] The 100°C viscosity of the low-viscosity hydrogenated base oil used is 1.879mm 2 / s, viscosity at 40°C is 7.84mm 2 / s, pour point -51°C, open flash point 154°C, Noack evaporation mass loss (250°C, 1h) 87.9%, paraffin content in composition 36.81% by mass, total naphthene content 63.19% by mass.

[0036] The 100°C viscosity of No. 4 hydrogenated base oil is 4.350mm 2 / s, viscosity at 40°C is 21.41, viscosity index is 102, pour point -24°C, open flash point 21...

example 3

[0039] Prepare low viscosity hydrogenated base oil, No. 8 hydrogenated base oil, bright stock 150BS and polyisobutylene viscosity index improver L3 in a mass ratio of 45:40:10:5. First add No. 8 hydrogenated base oil and 150BS into the blending kettle with a stirring device, then add low-viscosity hydrogenated base oil, stir at 40°C for 30 minutes, then add L3, heat up to 60°C and stir for 30 minutes, filter to obtain the blended The combined base oil composition is shown in Table 1 for the mass percentage of each component, and shown in Table 2 for its physical and chemical properties.

[0040] The 100°C viscosity of the low viscosity hydrogenated base oil used is 2.324mm 2 / s, viscosity at 40°C is 8.52mm 2 / s, viscosity index 79, pour point -48°C, open flash point 159°C, Noack evaporation mass loss (250°C, 1h) 82.6%, paraffin content in composition 36.99%, total naphthene content 62.98%, aromatic content 0.03 %.

[0041] The 100°C viscosity of No. 8 hydrogenated base oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com