Method for producing non-aqueous electrolyte secondary battery

一种非水电解质、制造方法的技术,应用在非水电解质蓄电池、二次电池、锂蓄电池等方向,能够解决火灾、电解液着火等问题,达到提高安全性、提高密封性、抑制闪点的降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

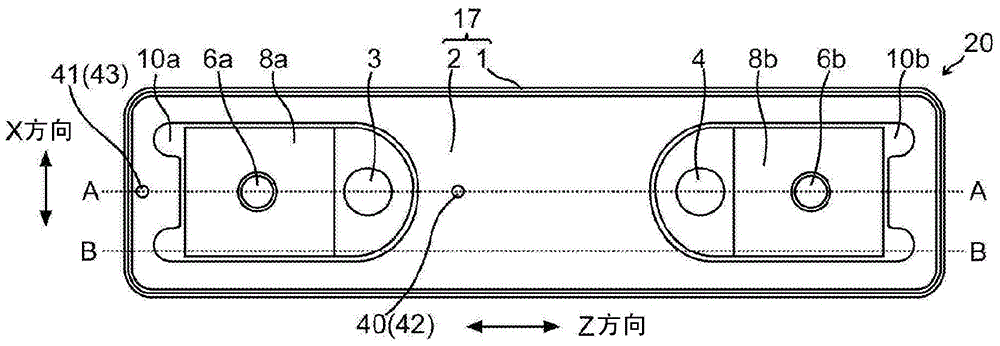

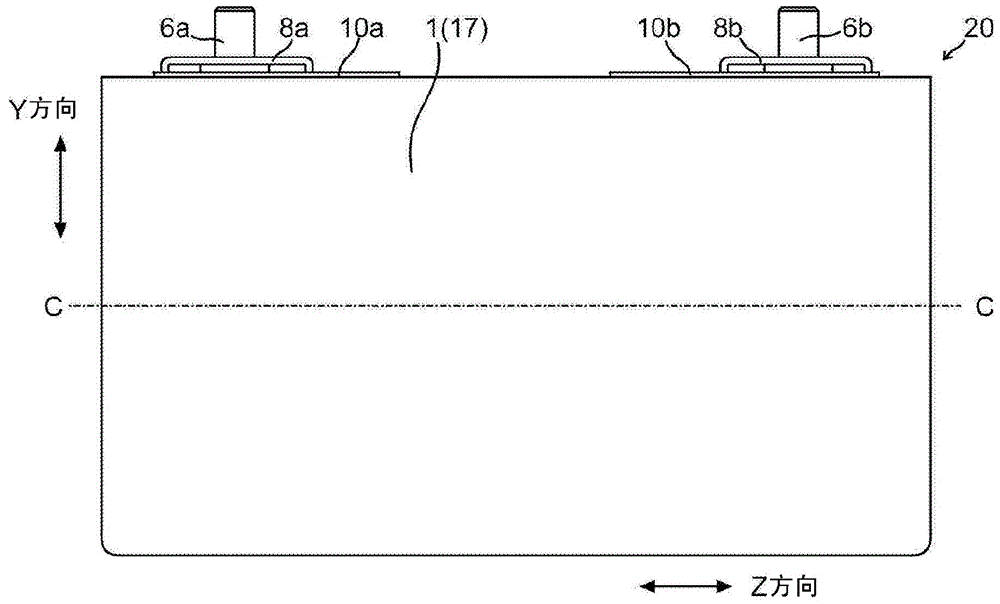

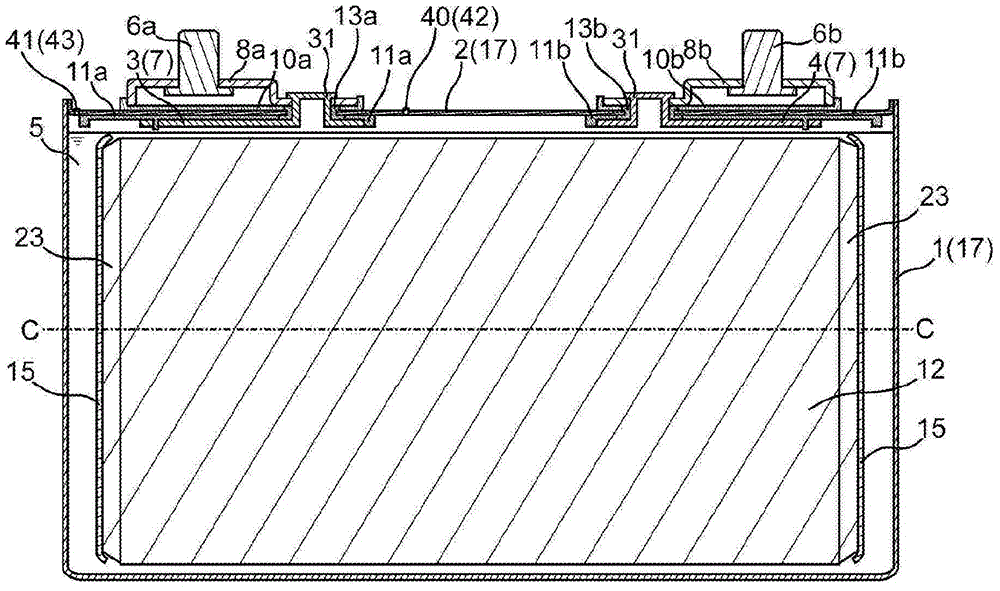

[0034] The manufacturing method of the non-aqueous electrolyte secondary battery according to the present invention is characterized in that the method includes the following steps: the step of putting the electrode body into the outer casing, the electrode body has a positive electrode containing a positive electrode active material and a negative electrode active material. The negative electrode of the material is a folded separator structure or a winding structure in which a separator is laminated between the positive electrode and the negative electrode; the step of putting a non-aqueous electrolyte that does not contain a flame retardant into the outer casing; by a step of applying a voltage between the positive electrode and the negative electrode placed in the outer case to charge the electrode body; a step of putting a flame retardant in the outer case; and a step of sealing the outer case , wherein the step of charging is a step of charging the electrode body in a stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com