Catalytic hydrocarbon reforming treatment method

A processing method and a technology for catalyzing hydrocarbons, which are applied in the fields of naphtha catalytic reforming, hydrocarbon distillation, and refined hydrocarbon oil, etc., which can solve problems such as high operating costs, scale limitations, and reduced diesel-gasoline ratio, and achieve short construction period and high construction efficiency. The effect of small investment and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

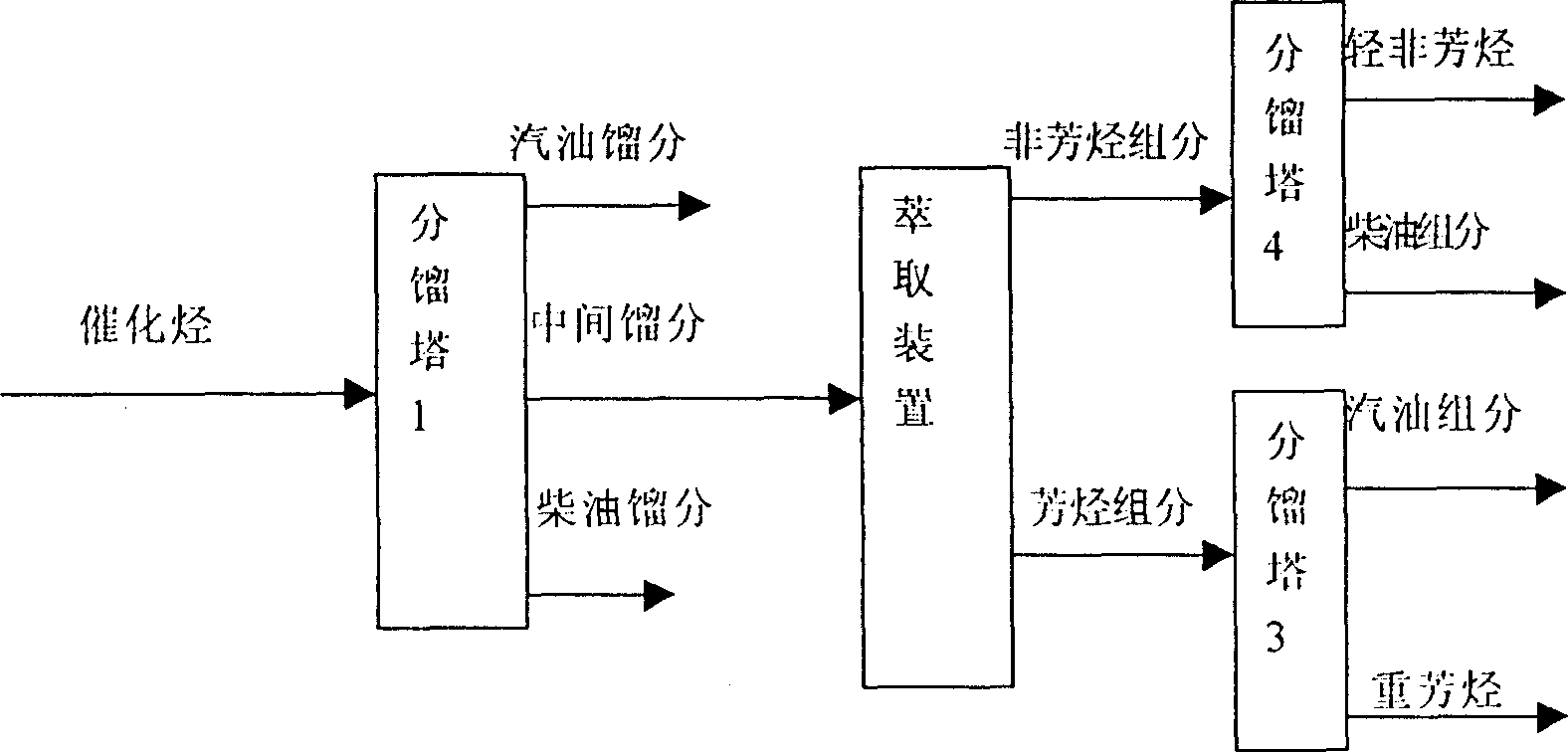

[0034] Such as figure 1As shown, the paraffin-based catalytic raw material and re-refined oil are produced under the action of the LCS catalyst produced by Lanzhou Catalyst Factory to produce catalytic hydrocarbons, and the obtained catalytic hydrocarbons are put into fractionation tower 1 for cutting and fractionation. 240°C, the temperature at the bottom of the tower is 370°C, the pressure at the top of the tower is 0.1MPa, and the pressure at the bottom of the tower is 0.12Mpa; add a side draw outlet in the middle of the fractionation tower 1 to cut the middle distillate, the temperature of the side draw outlet is 190°C, The distillation range of the middle distillate is 120-210°C. The obtained middle distillate is pumped into the extraction device for solvent extraction and separation. The solvent used is sulfolane, the extraction temperature is 80°C, the extraction pressure is 0.4MPa, and the solvent weight ratio (solvent / feed) is 4.8, and the aromatic components and non-...

Embodiment 2

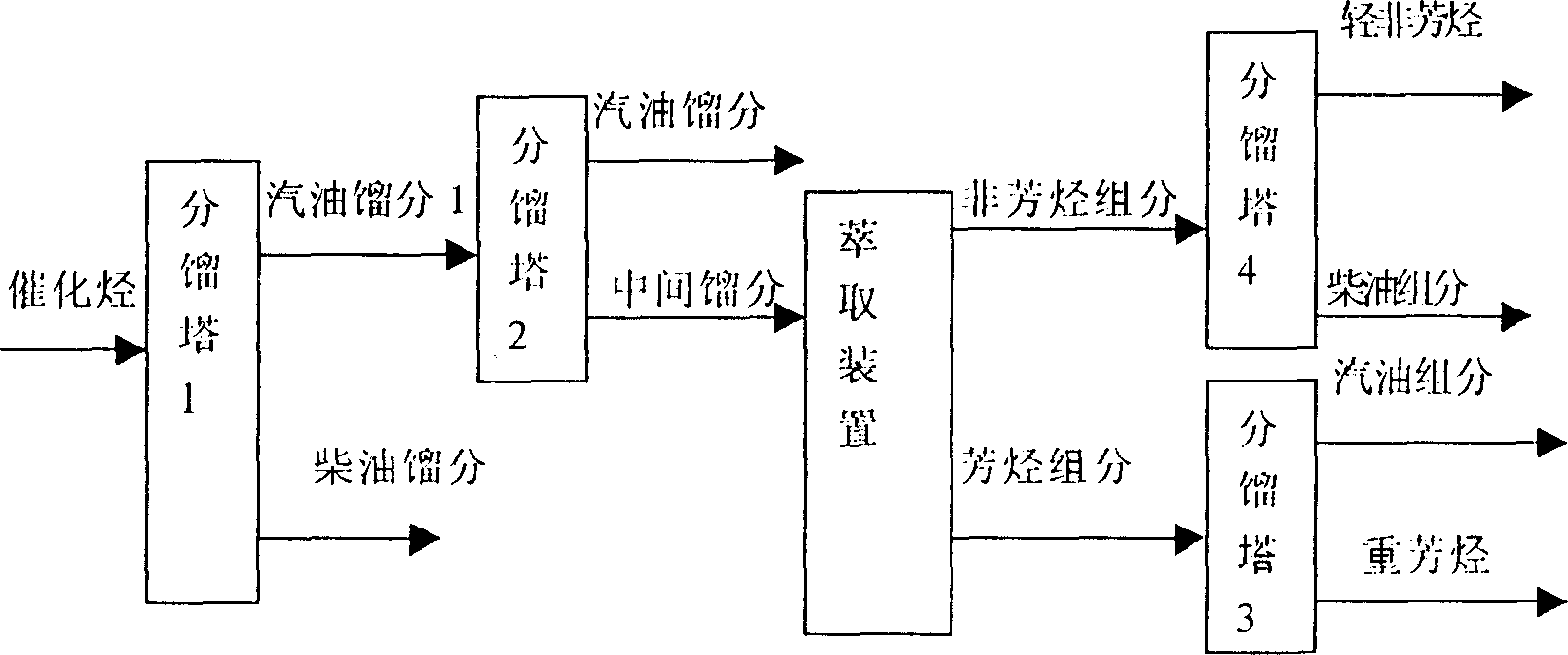

[0038] Catalytic hydrocarbons are produced by using the catalytic raw material of intermediate base heavy oil and recycled oil under the action of LANET-35 catalyst produced by Lanzhou Catalyst Factory, and the obtained catalytic hydrocarbons are put into fractionation tower 1 for cutting and fractionation. The temperature at the top of fractionation tower 1 is 80°C, and the diesel is exported The temperature is 240°C, the temperature at the bottom of the tower is 370°C, the pressure at the top of the tower is 0.1MPa, and the pressure at the bottom of the tower is 0.12Mpa; add three side draw outlets in the middle of the fractionation tower 1 to cut the middle distillate, from top to bottom three The outlet temperature of each side line is 170, 180, and 190°C in sequence, and the distillation ranges of the middle distillate are 80-120°C, 120-165°C, and 165-220°C respectively, and the obtained middle distillate of the three distillation ranges is pumped into three identical The ...

Embodiment 3

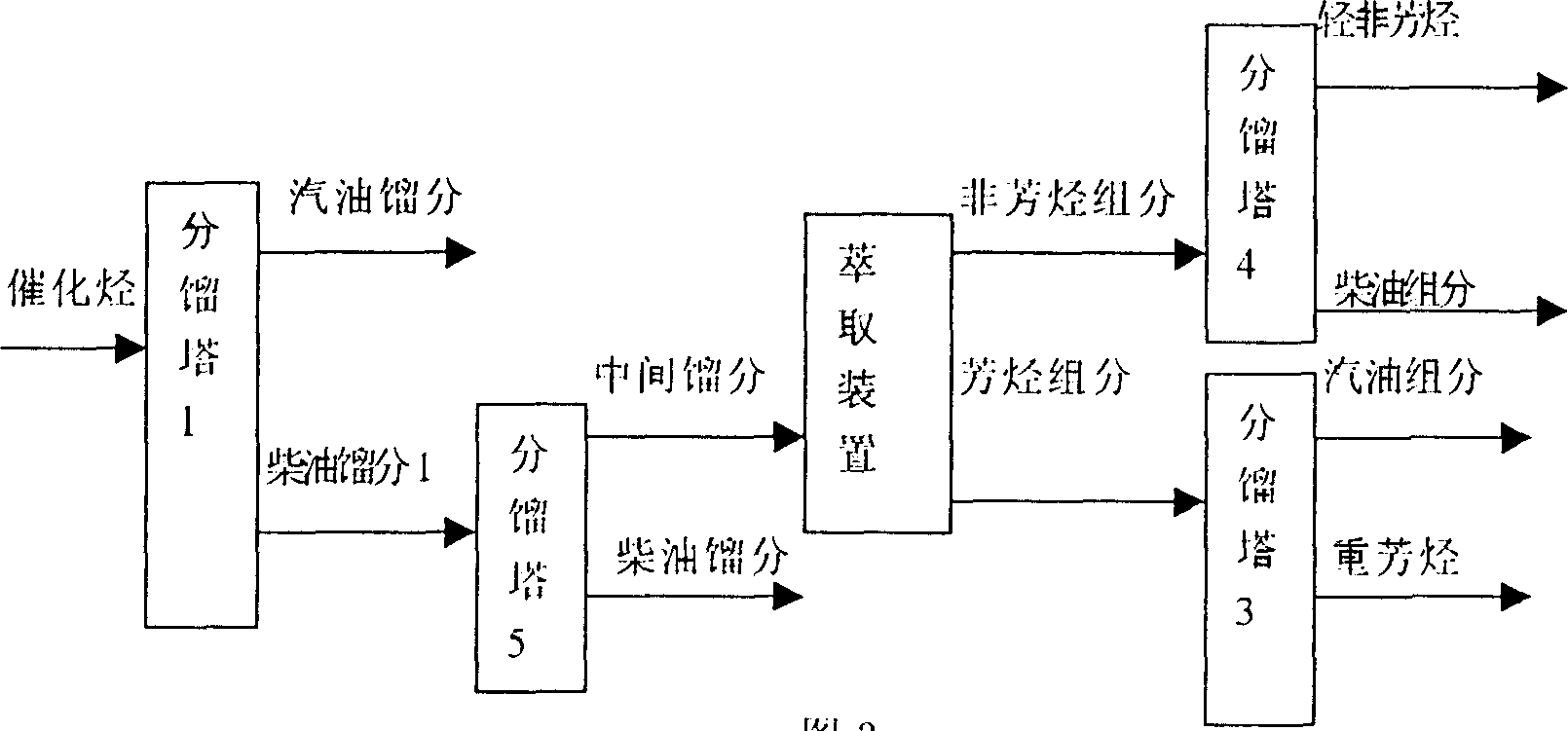

[0042] The catalytic raw material of naphthenic heavy oil and the re-refined oil are produced under the action of LANET-35 catalyst produced by Lanzhou Catalyst Factory to produce catalytic hydrocarbons, and the obtained catalytic hydrocarbons are put into fractionation tower 1 for cutting and fractionation. The temperature at the bottom of the tower is 240°C, the temperature at the bottom of the tower is 370°C, the pressure at the top of the tower is 0.18MPa, and the pressure at the bottom of the tower is 0.25Mpa; add two side draw outlets in the middle of the fractionation tower 1 to cut the middle distillate, two from top to bottom The temperature of the side line outlet is 180 and 190°C in sequence, and the distillation ranges of the middle distillate are 80-165°C and 165-220°C respectively, and the obtained middle distillate of the two distillation ranges is pumped into two identical extraction devices for solvent extraction , the solvent used is N-formyl morpholine, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com