Crystallization method of sodium ascorbate

A vitamin and crystallization technology, applied in the direction of organic chemistry, organic chemistry, etc., can solve the problems of poor color of vitamin C sodium products, affecting the color of vitamin C sodium, low yield of vitamin C sodium, etc., to promote stable growth and uniform particle size , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

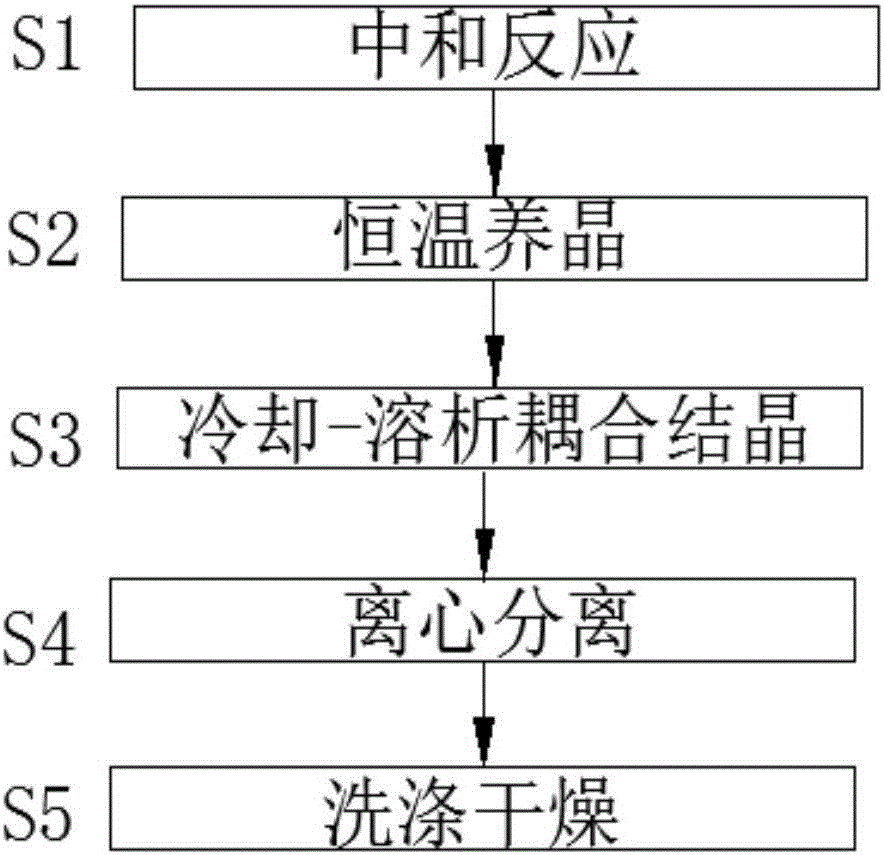

[0049] Neutralization reaction (S1): Add 300mL of distilled water into the reactor, then add 300g of vitamin C and 255g of sodium bicarbonate into the reactor, heat to 50°C, stir, and carry out the neutralization reaction for 30min, and control the terminal pH of the neutralization reaction The value is 4.5, and the reaction complete liquid is obtained, and the reaction complete liquid is filtered with a 0.22 μm organic filter membrane, and the filtration temperature is 50° C., to obtain the reaction clear liquid;

[0050] Constant temperature crystal growth (S2): Add 0.35 g of 200-mesh sodium vitamin C seed crystals to the reaction clarified liquid to obtain a seed crystal suspension, and grow the crystal seed suspension at 50° C. for 1.5 hours to obtain a crystal growth complete liquid;

[0051] Cooling-dissolution coupled crystallization (S3): Cool the crystal growth complete solution to 25°C at a uniform speed, and the cooling time is 2 hours, and cool and crystallize to ob...

Embodiment 2

[0055] Neutralization reaction (S1): Add 360mL of distilled water into the reactor, then add 300g of vitamin C and 270g of sodium bicarbonate into the reactor, heat to 50°C, stir, and carry out the neutralization reaction for 40min, and control the terminal pH of the neutralization reaction The value is 5, and the reaction complete liquid is obtained, and the reaction complete liquid is filtered with a 0.22 μm organic filter membrane, and the filtration temperature is 50° C., to obtain the reaction clear liquid;

[0056] Constant temperature crystal growth (S2): Add 0.4 g of 180-mesh sodium vitamin C seed crystal to the reaction clarified liquid to obtain a seed crystal suspension, and grow the seed crystal suspension at 50° C. for 1 hour to obtain a crystal growth complete liquid;

[0057] Cooling-dissolution coupling crystallization (S3): Cool down the crystal growth complete liquid to 25°C at a uniform speed, and the cooling time is 2.5 hours, and cool and crystallize to obt...

Embodiment 3

[0061] Neutralization reaction (S1): Add 270mL of distilled water into the reactor, then add 300g of vitamin C and 240g of sodium bicarbonate into the reactor, heat to 55°C, stir, and carry out the neutralization reaction for 35min, and control the terminal pH of the neutralization reaction The value is 5.5, and the reaction complete liquid is obtained, and the reaction complete liquid is filtered with a 0.22 μm organic filter membrane, and the filtration temperature is 55° C., to obtain the reaction clear liquid;

[0062] Constant temperature crystal growth (S2): Add 0.43 g of 190-mesh sodium vitamin C seed crystals to the reaction clarified liquid to obtain a seed crystal suspension, and grow the seed crystal suspension at 55° C. for 1 hour to obtain a crystal growth complete liquid;

[0063] Cooling-dissolution coupled crystallization (S3): Cool down the crystal-growing liquid to 25°C at a uniform speed, and the cooling time is 2.5 hours, and cool and crystallize to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com