A long-term stabilization treatment method for arsenic-containing waste liquid arsenic

A technology for stabilizing treatment and waste liquid, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of high bulk density of scorodite in landfill, reduce the bulk density of scorodite, and avoid iron salts. The effect of polymer production, maintaining long-term stability, and increasing the rate of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

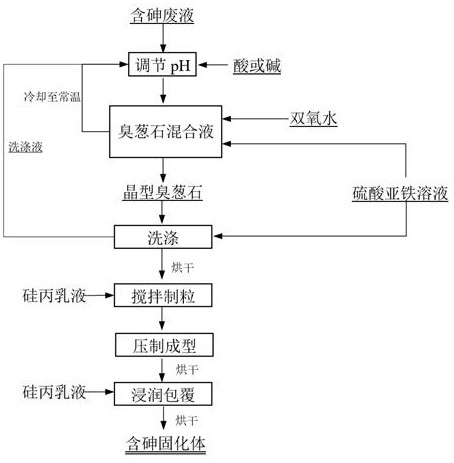

Method used

Image

Examples

Embodiment 1

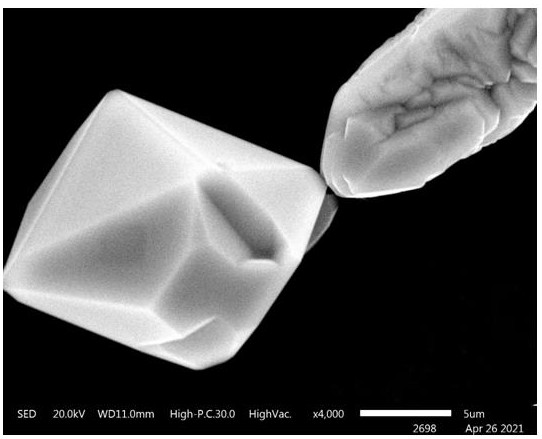

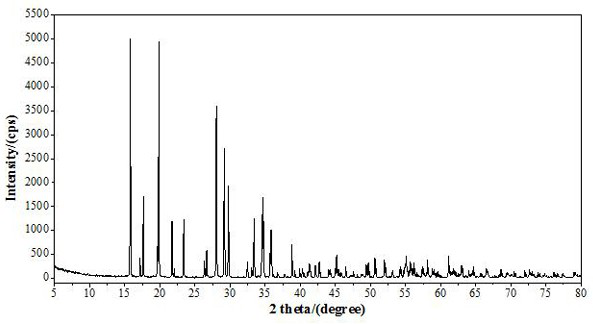

[0037] Synthesis of high-purity crystal scorodite:

[0038] The arsenic-containing waste liquid is the oxidation leaching liquid of arsenic sulfide slag, the concentration of arsenic is 25g / L, measure 500mL into a three-necked flask, put it into a magnetic rotor, and put it into a magnetic oil bath. According to the molar ratio of iron to arsenic of 2, weigh ferrous sulfate to prepare a solution, set the volume to 200mL, dilute hydrogen peroxide to a mass concentration of 5%, and connect the ferrous sulfate solution and hydrogen peroxide to a peristaltic pump. Sodium carbonate is prepared into a solution with a mass concentration of 30%, the pH is adjusted, and the pH meter and the redox potential are connected to the flask. Turn on the stirring, adjust the initial pH value of the arsenic-containing waste liquid to 2.00 with sodium carbonate solution, set the temperature of the magnetic heating stirrer at 60°C, turn on the heating, reach the set temperature, add ferrous sulfat...

Embodiment 2

[0042] Synthesis of high-purity crystal scorodite:

[0043] The arsenic-containing waste liquid is the oxidation leaching liquid of arsenic sulfide slag, the concentration of arsenic is 25g / L, measure 500mL into a three-necked flask, put it into a magnetic rotor, and put it into a magnetic oil bath. According to the molar ratio of iron to arsenic of 1.5, ferrous sulfate was weighed to prepare a solution, and the volume was fixed to 150mL. The hydrogen peroxide was diluted to a mass concentration of 5%, and the ferrous sulfate solution and hydrogen peroxide were connected to a peristaltic pump. Weigh sodium carbonate, prepare a solution with a mass concentration of 30%, and adjust the pH. Connect the pH meter and ORP to the flask. Turn on the stirring, adjust the initial pH value of the arsenic-containing waste liquid to 1.50 with sodium carbonate solution, set the temperature of the magnetic heating stirrer at 75°C, turn on the heating, reach the set temperature, add ferrous ...

Embodiment 3

[0047] Synthesis of high-purity crystal scorodite:

[0048] The arsenic-containing waste liquid is the oxidation leaching liquid of arsenic sulfide slag, the concentration of arsenic is 25g / L, measure 500mL into a three-necked flask, put it into a magnetic rotor, and put it into a magnetic oil bath. According to the molar ratio of iron to arsenic of 1.2, ferrous sulfate was weighed to prepare a solution, and the constant volume was 125mL, and hydrogen peroxide was diluted to a mass concentration of 5%, and the ferrous sulfate solution and hydrogen peroxide were connected to a peristaltic pump. Weigh sodium carbonate, prepare a solution with a mass concentration of 30%, and adjust the pH. Connect the pH meter and ORP to the flask. Turn on stirring, adjust the initial pH value of the arsenic-containing waste liquid to 1.00 with sodium carbonate solution, set the temperature of the magnetic heating stirrer at 95°C, turn on the heating until the set temperature is reached, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com