Method for preparing acrylic resin coated nano-drug by solid wall fiber pipe bundle crystallizer

An acrylic resin, nano-drug technology, applied in the directions of drug delivery, pharmaceutical formulations, medical preparations with non-active ingredients, etc., can solve the problems of inability to separate hard agglomerates, uneven quality, low production efficiency, etc., to eliminate product Unstable quality, energy and cost savings, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

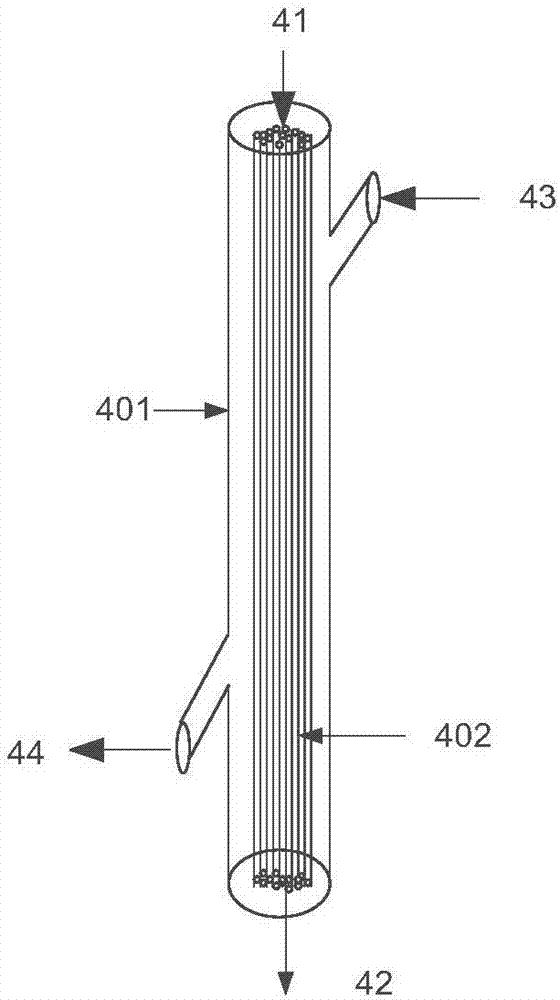

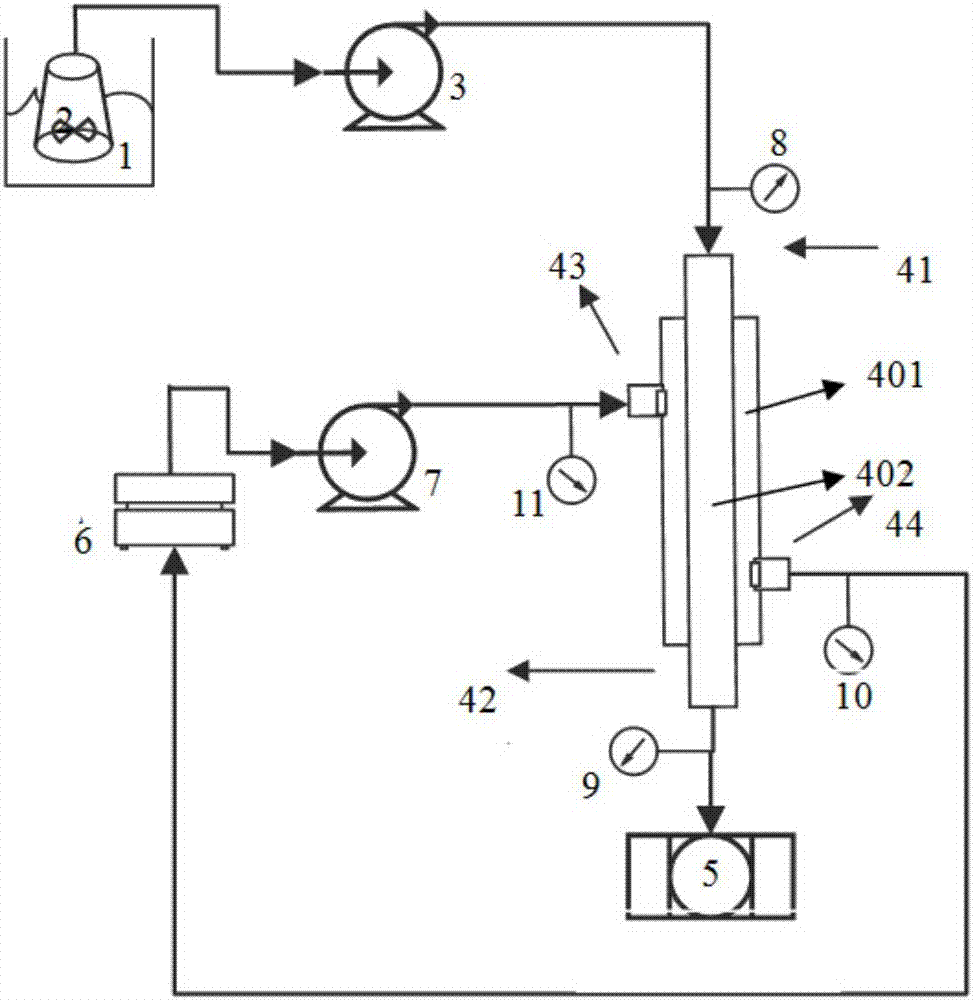

[0035] see Figure 1~3 , the embodiment of the present invention uses an acrylic resin-coated nano-medicine preparation device, and the acrylic resin-coated nano-medicine preparation device is equipped with a water bath device 1, a dissolving drug bottle 2, a first peristaltic pump 3, a fiber tube bundle crystallizer, and a vacuum filtration system 5. Refrigerator 6 and the 2nd peristaltic pump 7; described dissolving drug bottle 2 is arranged in water bath device 1, and described fiber tube bundle crystallizer is provided with outer pipe 401 and inner pipe 402, and inner pipe 402 is arranged in outer pipe 401, The dissolved drug bottle 2 is connected to the inlet of the first peristaltic pump 3, the outlet of the first peristaltic pump 3 is connected to the inner tube inlet 41 of the fiber tube bundle crystallizer, and the inner tube outlet 42 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com