Low-temperature method for manufacturing nano-MgO crystal whisker

A whisker and nano technology is applied in the field of low-temperature preparation of nano-MgO whiskers, which can solve the problem of requiring a long time and achieve the effect of increasing the stay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

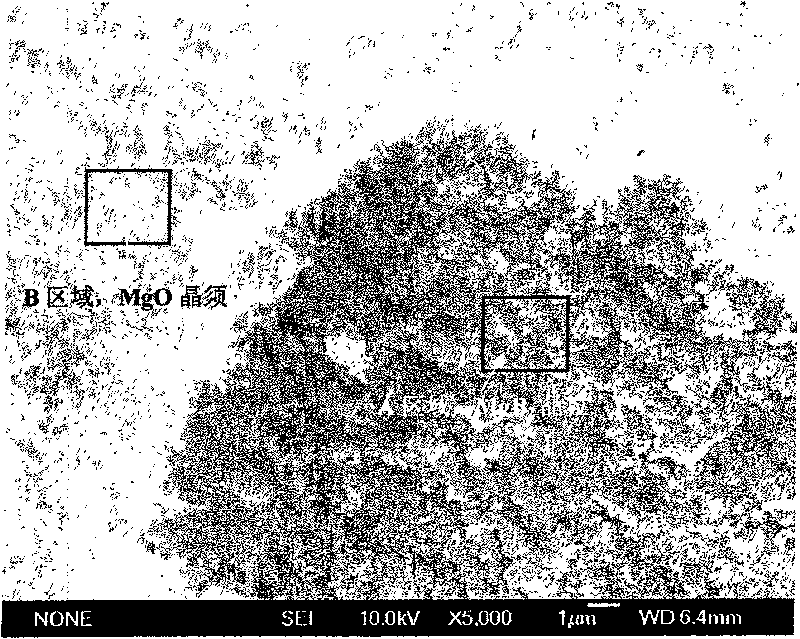

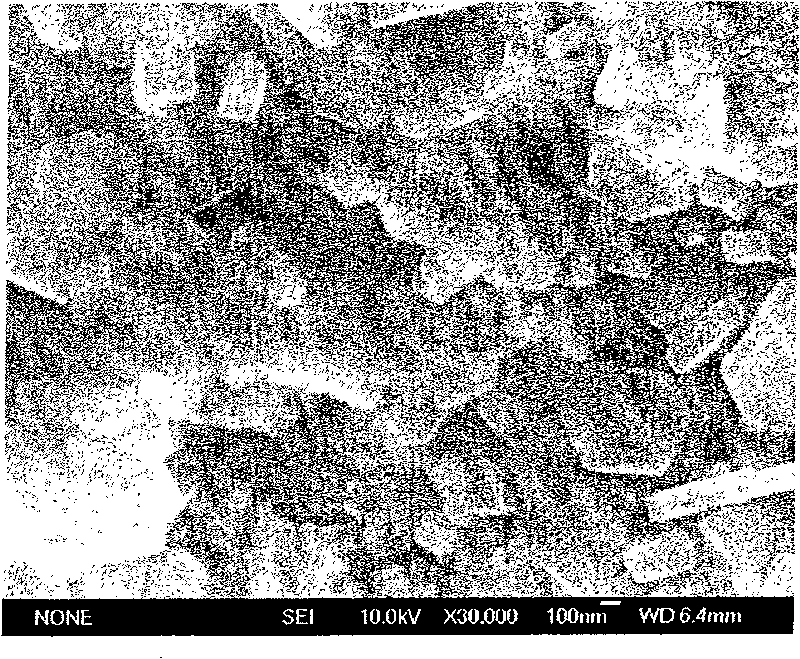

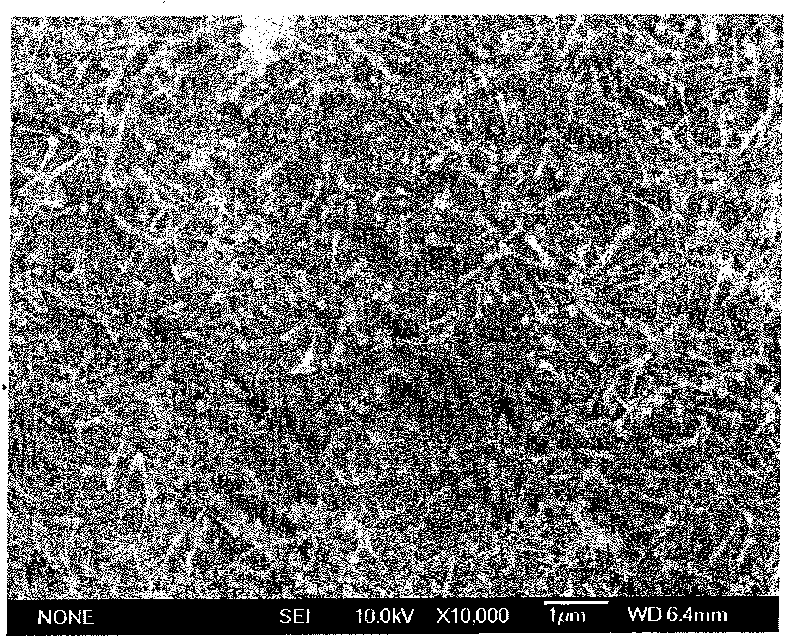

[0023] Mix the magnesium powder with a purity of 99.5% and the amorphous boron powder with a purity of 99% according to the atomic ratio of Mg:B=1:2, and grind them in an agate mortar for 120 minutes to make them fully mixed. Mix the powder with a press at 5kg / cm 3 Press it into a sintered block under a certain pressure and put it into a BN crucible, then put the crucible vertically into the heating zone of the vacuum tube furnace, then seal the tube furnace and vacuumize it to 1Pa, then fill it with 5% oxygen The argon gas is used, and the flow rate of the mixed gas is controlled at 5 lit. / min. Finally, set the temperature program. After the sample is heated to 750°C at a heating rate of 5K / min, it is immediately lowered to room temperature at the same rate without heat preservation treatment. figure 2 MgB shown 2 The grain surface is formed as figure 1 The nano-MgO whiskers are shown, and the generated nano-MgO whiskers are scattered like image 3 shown.

Embodiment 2

[0025] The analytically pure magnesium powder and the amorphous analytically pure boron powder were mixed according to the atomic ratio of Mg:B=1.2:2, and ground in a corundum mortar for 60 minutes to make them fully mixed. Mix the powder with a press at 8kg / cm 3 Press it into a sintered block under a certain pressure and put it into a corundum crucible, then put the crucible into the heating zone of the vacuum tube furnace, then seal the tube furnace and evacuate it to 5Pa, then fill it with argon gas mixed with 3% oxygen , the mixed gas flow rate is controlled at 10lit. / min. Finally, set the temperature program, heat the sample to 720°C at a heating rate of 10K / min, keep it for 30 minutes, and then lower it to room temperature at the same rate. 2 Linear nano-MgO whiskers are generated on the grain surface, such as Figure 4 shown.

Embodiment 3

[0027] The analytically pure magnesium powder and the amorphous analytically pure boron powder were mixed according to the atomic ratio of Mg:B=1.5:2, and ground in an agate mortar for 120 minutes to make them fully mixed. Mix the powder with a press at 10kg / cm 3 Press it into a sintered block under a certain pressure and put it into a graphite crucible, then put the crucible into the heating zone of the vacuum tube furnace, then seal the tube furnace and evacuate it to 10Pa, then fill it with argon gas mixed with 2% oxygen , the mixed gas flow rate is controlled at 20 liters / min. Finally, set the temperature program, heat the sample to 650°C at a heating rate of 20K / min, keep it warm for 120min, and then lower it to room temperature at the same rate. Rod-shaped nano-MgO whiskers can be formed on the surface of the sample, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com