Method for in-situ growth of potassium dihydrogen phosphate single crystal in environmental scanning electronic microscope

A potassium dihydrogen phosphate single and environmental scanning electron microscope technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem that non-conductive materials cannot be directly observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

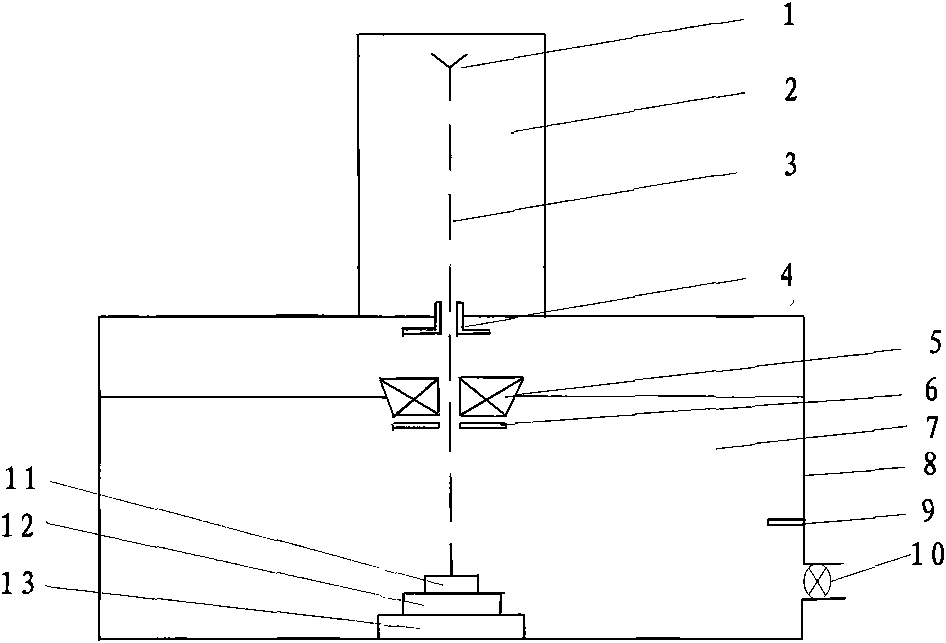

[0030] 1) fixing potassium dihydrogen phosphate (KDP) polycrystalline powder on the sample stage (11) in the environmental scanning electron microscope sample chamber (7);

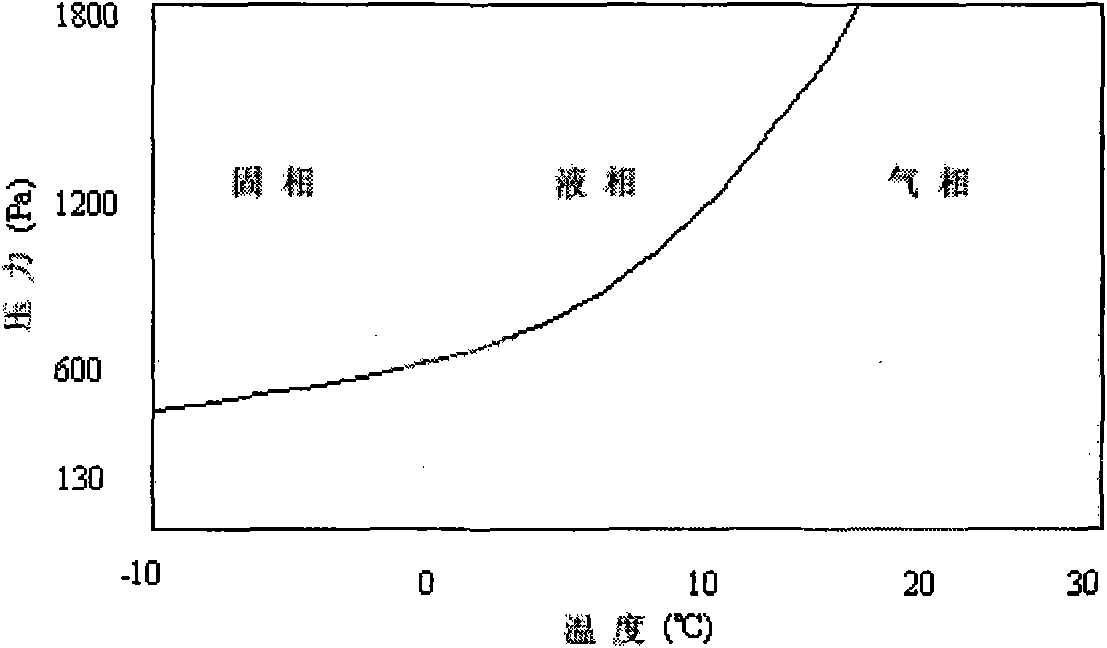

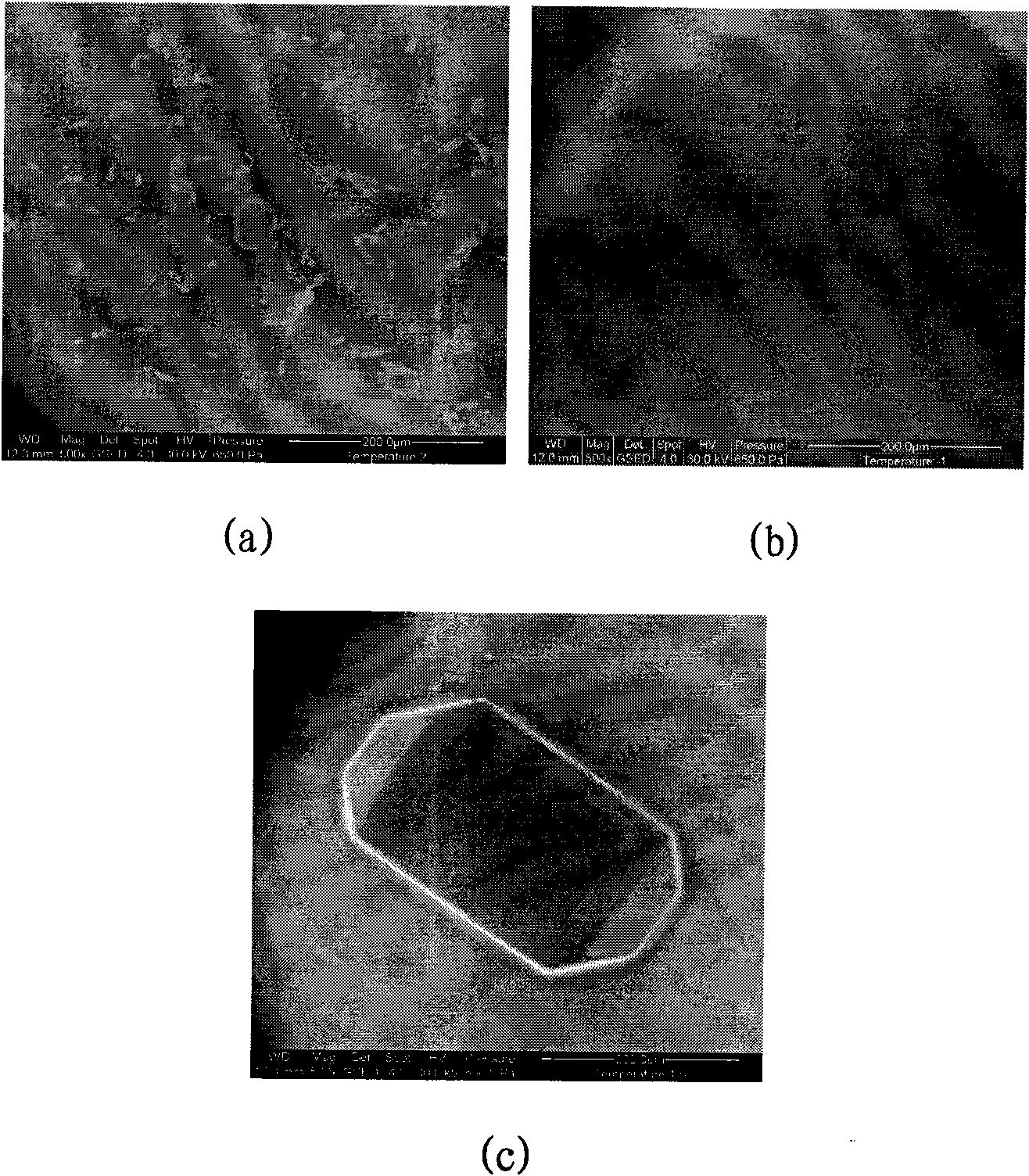

[0031] 2) At 2°C, vacuumize the environmental scanning electron microscope sample chamber (7) to 650Pa, so that %, observe the microscopic morphology of KDP polycrystalline powder, such as image 3 as shown in (a);

[0032] 3) Adjust the temperature of the sample stage (11) to -1°C, and keep the pressure of the sample chamber (7) at 650Pa, so that The water vapor in the sample chamber condenses into a liquid state on the sample stage (11), so that the KDP polycrystalline powder is dissolved and observed in situ, such as image 3 as indicated in (b);

[0033] 4) After the KDP polycrystalline powder is completely dissolved, keep the pressure of the sample chamber (7) constant at 650Pa, and adjust the temperature to 1.5°C so that And keep it for 3 hours, so that KDP grows in the form of single crystal, a...

Embodiment 2

[0036] 1) fixing the KDP polycrystalline powder on the sample stage (11) in the environmental scanning electron microscope sample chamber (7);

[0037] 2) At 2.1°C, the environmental scanning electron microscope sample chamber (7) is evacuated to 400Pa, so that Observe the microscopic morphology of KDP polycrystalline powder, such as Figure 4 as shown in (a);

[0038] 3) Adjust the temperature of the sample stage (11) to 1°C, and increase the pressure of the sample chamber to 670Pa, so that The water vapor in the sample chamber condenses into a liquid state on the sample stage, so that the KDP polycrystalline powder is dissolved and observed in situ, such as Figure 4 as indicated in (b);

[0039] 4) After the KDP polycrystalline powder is dissolved, keep the temperature of the sample stage (11) at 1°C, and adjust the pressure of the sample chamber (7) to 600Pa, so that And keep it for 66 minutes, so that KDP grows in the form of single crystal, and observe the morph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com