Domestic ceramic raw material whiteness proficiency testing sample

A technology of proficiency verification and ceramic raw materials, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems such as the whiteness of daily-use ceramic raw materials, and achieve the effect of high success rate and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 is the best embodiment.

[0026] Example 1

[0027] (1) Preparation of ultrafine zirconia:

[0028] Weigh 50.00 g of zirconium oxychloride octahydrate into a 1 L three-neck flask, add 540 ml of distilled water, slowly add 90 ml of 30% ammonia water dropwise with a dropping funnel, and stir vigorously for 1 hour to obtain a white precipitate; Vacuum filtration, washed 4 times with double distilled water, when the pH is 7.0, stop washing, put the sample in an oven and dry it at 105°C for 24 hours, then calcined in a muffle furnace at 380°C for 3h, the calcined sample After cooling, put it into an electromagnetic pulverizer for grinding, and the ground powder is sieved.

[0029] The zirconia content of the sample was analyzed by X-ray fluorescence spectroscopy to be 99.91%, and the average particle size of the sample was measured by a laser scattering particle size distribution analyzer to be 23.55 μm.

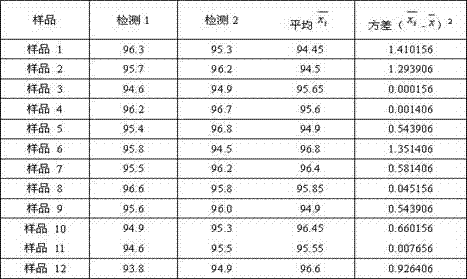

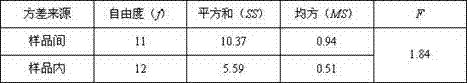

[0030] (2) Uniformity and stability testing:

[0031...

Embodiment 2

[0052] (1) Preparation of ultrafine zirconia:

[0053] Weigh 50.00 g of zirconium tetrachloride in a 1 L three-necked flask, add 390 ml of distilled water, slowly add 65 ml of 30% ammonia water dropwise with a dropping funnel, and stir vigorously for 1 hour to obtain a white precipitate; vacuum filter the white precipitate prepared above , washed 5 times with double distilled water, when the pH was 7.1, stop washing, put the sample in an oven and dry at 100°C for 25 hours, then calcined in a muffle furnace at 385°C for 4h, after cooling the calcined sample Put it into an electromagnetic pulverizer for grinding, and the ground powder is sieved and placed in a desiccator.

[0054] The zirconia content of the sample was analyzed by X-ray fluorescence spectroscopy to be 99.86%, and the average particle size of the sample was measured by a laser scattering particle size distribution analyzer to be 29.97 μm.

[0055] (2) Uniformity and stability testing:

[0056] Detect its unifor...

Embodiment 3

[0067] (1) Preparation of ultrafine zirconia:

[0068] Weigh 50.00 grams of zirconium oxychloride octahydrate into a 1 L three-neck flask, add 500 ml of distilled water, slowly add 100 ml of 30% ammonia water dropwise with a dropping funnel, and stir vigorously for 1 hour to obtain a white precipitate; Vacuum filtration, washed 4 times with twice distilled water, when the pH is 7.0, stop washing, put the sample in an oven and dry it at 110°C for 26 hours, then calcinate it in a muffle furnace at 500°C for 4h, and the calcined sample After cooling, put it into an electromagnetic pulverizer for grinding, and the ground powder is sieved.

[0069] The zirconia content of the sample was analyzed by X-ray fluorescence spectroscopy to be 99.45%, and the average particle size of the sample was measured by a laser scattering particle size distribution analyzer to be 31.09 μm.

[0070] (2) Uniformity and stability testing:

[0071] Take a 15.00g sample and place it in the mold of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com