Etching device and etching method of artificial quartz crystal seed wafer

A quartz crystal and chip corrosion technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of high corrosion intensity, fast corrosion speed, corrosion and perforation of seed wafers, etc., to improve accuracy and ensure cleanliness degree, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

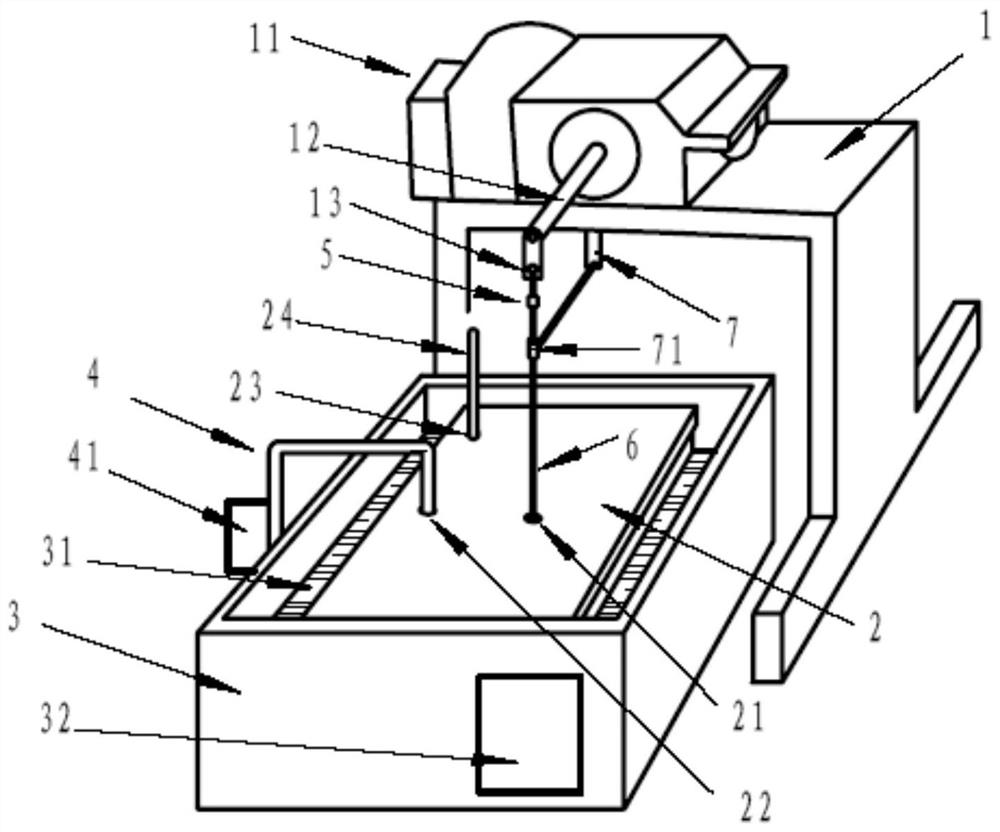

[0048] Embodiment 1, quartz crystal seed wafer corrosion control device, such as Figure 1-3 Shown; including seed wafer corrosion main frame 1, corrosion box 2, water bath box 3 and fixed ventilation pipe 4.

[0049] Seed wafer corrosion main body frame 1 is provided with seed wafer corrosion main machine operation timer 11 and the rotating shaft 12 of the seed wafer corrosion main machine with motor; The rotating shaft 12 is fixedly provided with telescopic draw bar 13; The rotating shaft 12 is horizontally arranged , the draw bar 13 is vertically arranged with the rotating shaft 12 . The motor can drive the rotating shaft 12 to rotate, and the rotating shaft 12 drives the drawbar 13 to rotate together.

[0050] The case cover (top) of the corrosion box 2 is provided with a traction through hole 21, a ventilation pipe hole 22 and a temperature measuring hole 23.

[0051] The corrosion box 2 is placed in the water bath box 3 directly below the rotating shaft 12 (draw bar 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com