A preparation process and device system for continuous cooling and recrystallization of ethyl carbazole

A technology of ethylcarbazole and a preparation process, which is applied in the field of preparation technology and device system of continuous cooling and recrystallization of ethylcarbazole, can solve the problems of improper control of process parameters, deterioration of ethylcarbazole, small crystal size and the like, and achieves Guaranteed crystal size, improved crystal growth, and reduced moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

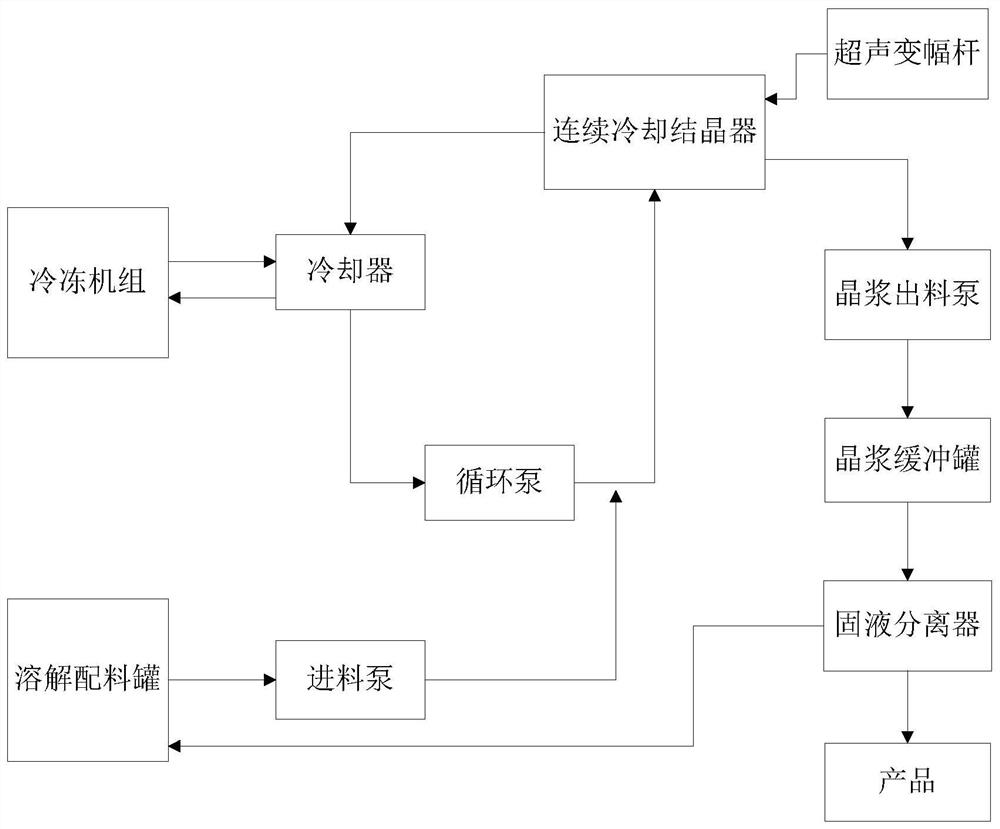

[0039] The present embodiment provides a preparation process for continuous cooling and crystallization of ethylcarbazole, comprising the following steps:

[0040] Step 1: Mix the crude ethylcarbazole and the ethanol solvent in a mass ratio of 25:100, add it to the continuous cooling crystallizer, until the solution reaches the specified liquid level, where the temperature is about 60 °C, turn on the external circulation pump And the refrigeration unit, adjust the freezing settings, and conduct the first cooling, and the cooling rate is 3 °C / h;

[0041] Step 2: When the temperature of the solution reaches 52°C, add ethylcarbazole seed crystals with a particle size of 0.05mm to 0.1mm in an amount of 10‰, and after 45min of heat preservation, conduct a second cooling, and the cooling rate is 4°C / h , until the temperature drops to 10°C to obtain the mother liquor of continuous crystallization;

[0042] Step 3: Add the pre-configured raw material liquid with a temperature of 60 °C ...

Embodiment 2

[0045] The present embodiment provides a preparation process for continuous cooling and crystallization of ethylcarbazole, comprising the following steps:

[0046] Step 1: Mix the crude ethylcarbazole and ethanol solvent in a mass ratio of 22:100 and add it to the continuous cooling crystallizer until the solution reaches the specified liquid level, where the temperature is about 55°C, and the external circulation pump is turned on. And the refrigeration unit, adjust the freezing settings, and conduct the first cooling, and the cooling rate is 3.5 °C / h;

[0047] Step 2: When the temperature of the solution reaches 51°C, add ethylcarbazole seed crystals with a particle size of 0.05mm to 0.1mm, and the addition amount is 10‰, and after 30min of heat preservation, the second cooling is performed, and the cooling rate is 4°C / h , until the temperature drops to 10°C to obtain the mother liquor of continuous crystallization;

[0048] Step 3: Add the pre-configured raw material liqui...

Embodiment 3

[0051] The present embodiment provides a preparation process for continuous cooling and crystallization of ethylcarbazole, comprising the following steps:

[0052] Step 1: Mix the crude ethylcarbazole and ethanol solvent in a mass ratio of 30:100, and add it to the continuous cooling crystallizer until the solution reaches the specified liquid level, where the temperature is about 53 °C, and the external circulation pump is turned on. And the refrigeration unit, adjust the freezing settings, and conduct the first cooling, and the cooling rate is 4 °C / h;

[0053] Step 2: When the temperature of the solution reaches 53°C, add ethylcarbazole seed crystals with a particle size of 0.05mm to 0.1mm, and the addition amount is 10‰, and after 60min of heat preservation, the second cooling is performed, and the cooling rate is 4°C / h , until the temperature drops to 10°C to obtain the mother liquor of continuous crystallization;

[0054] Step 3: Add the pre-configured raw material liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com