NiO/MXene composite material as well as preparation method and application thereof

A composite material, mass ratio technology, applied in chemical instruments and methods, offensive equipment, explosives processing equipment, etc., can solve the problems affecting excellent characteristics, easy agglomeration particle size of nanomaterials, enlargement, etc., to improve catalytic activity and cost. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: prepare MXene

[0029] Weigh 2gMAX (Ti 3 AlC 2 ) into a polytetrafluoroethylene beaker, slowly add 40ml of HF acid with a concentration of 40wt% into the beaker, then place the beaker in a water bath at 60°C, stir continuously for 18 hours, wash, centrifuge, and vacuum freeze-dry after the stirring 24h, get black powder MXene (Ti 3 C 2 )sample.

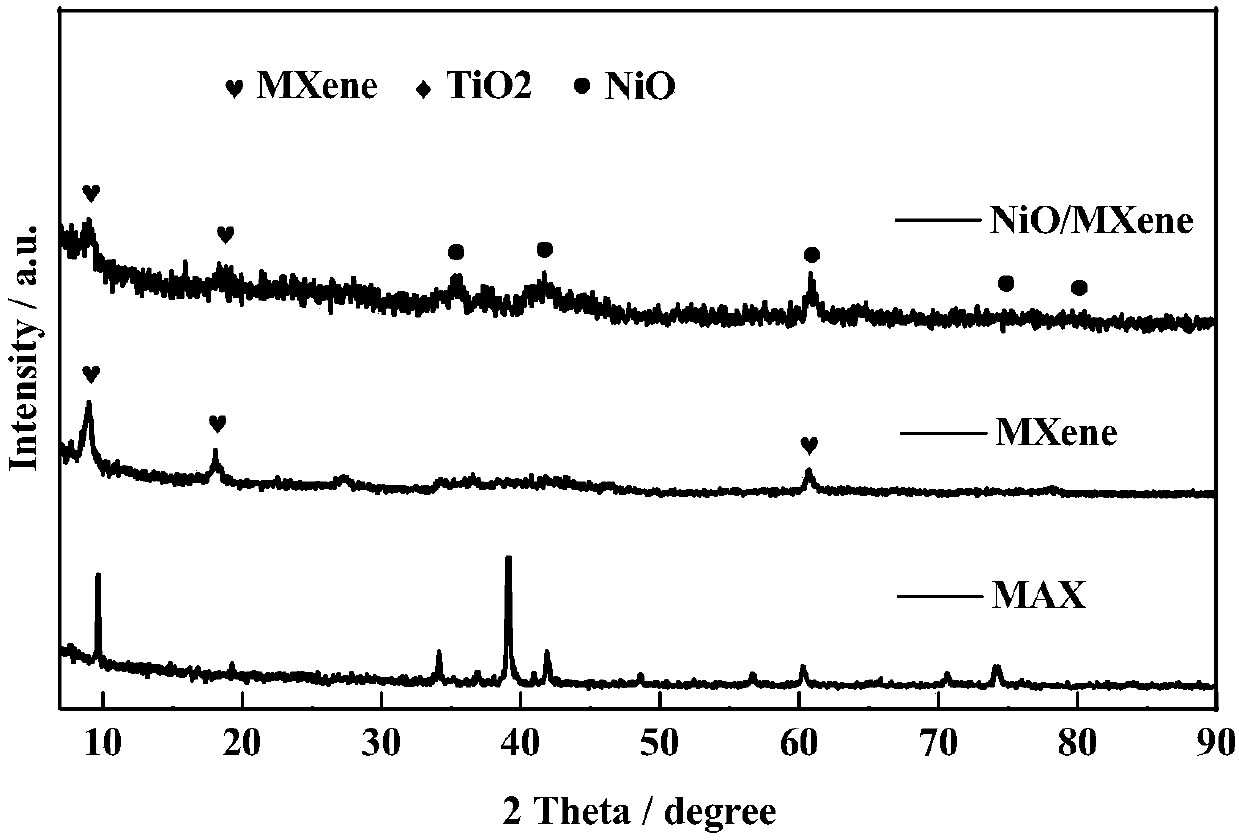

[0030] With the material prepared by MAX and embodiment 1, after scanning by X-ray diffractometer, see figure 1 , for Ti 3 AlC 2 and MXene;

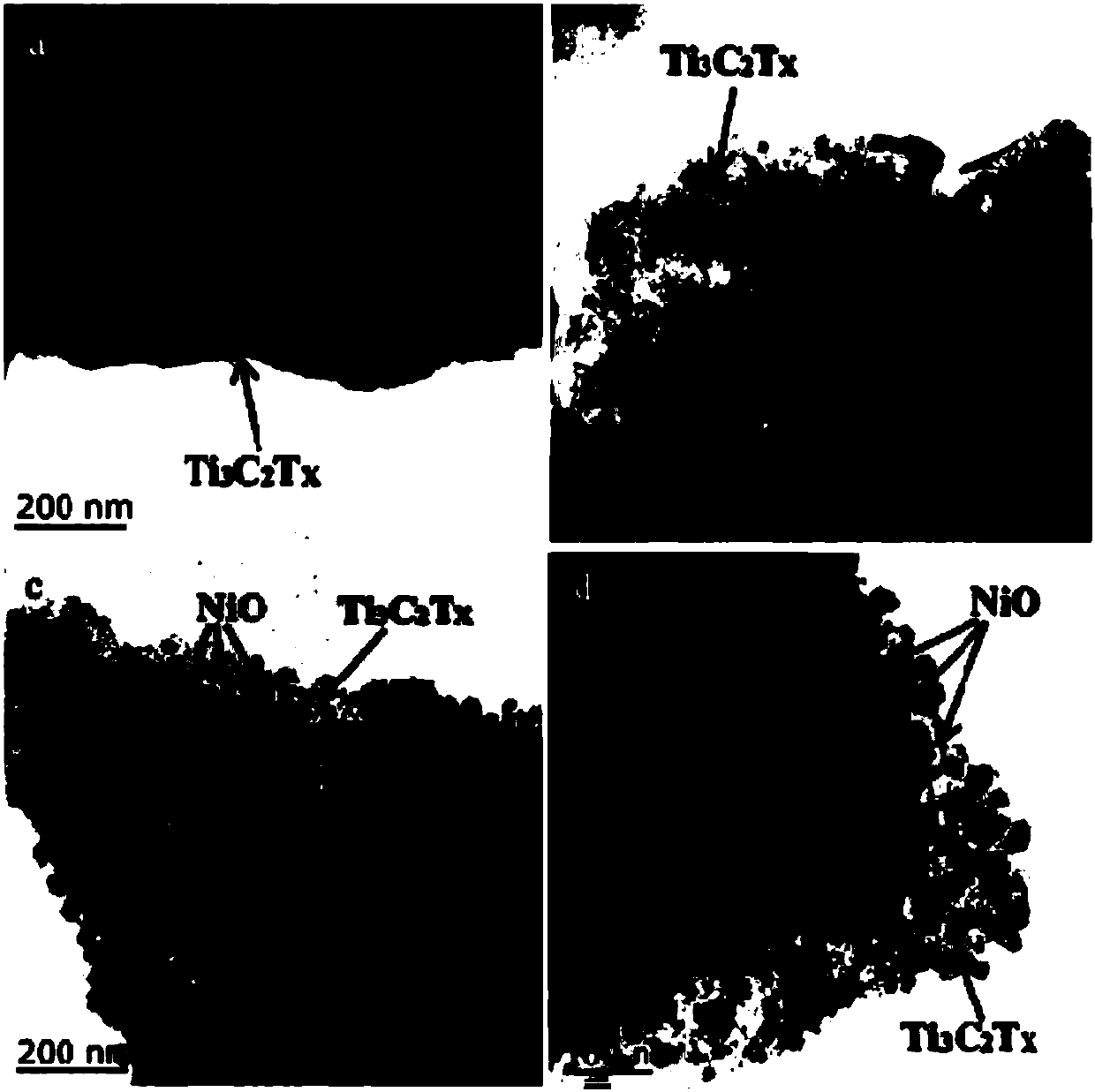

[0031] With the material prepared by MAX and embodiment 1, after scanning electron microscope observation, see figure 2 , you can see the typical block structure of MAX, and the typical accordion-like structure of MXene;

Embodiment 2

[0032] Embodiment 2: prepare NiO / MXene composite material

[0033] (1) According to the method of Example 1, MXene (Ti 3 C 2 );

[0034] (2) 38mgNiSO 4 ·6H 2 O was placed in 30ml deionized water, then 0.2g of MXene prepared in step (1) was added, and mixed and stirred for 30min;

[0035] (3) Prepare 30ml of a solution containing 12mg of NaOH, and add it dropwise to the mixed solution in step (2), and keep stirring for 2h, then wash, centrifuge, and vacuum freeze-dry for 24h;

[0036] (4) Place the sample obtained in step (3) in a tube furnace, raise the temperature to 350°C at a rate of 5°C / min, and keep it warm for 2 hours to obtain a NiO / MXene composite material. The preparation process is as follows Figure 5 .

[0037] With the material prepared in embodiment 2, after X-ray diffractometer scanning, see figure 1 , is NiO / MXene composite material;

[0038] By the material prepared in embodiment 2, after scanning electron microscope observation, see figure 2 , it ca...

Embodiment 3

[0040] Embodiment 3: prepare NiO / MXene composite material

[0041] (1) According to the method of Example 1, MXene (Ti 3 C 2 );

[0042] (2) 78mgNiSO 4 ·6H 2 O was placed in 30ml deionized water, then 0.2g of MXene prepared in step (1) was added, and mixed and stirred for 30min;

[0043] (3) Prepare 30ml of a solution containing 24mg of NaOH, and add it dropwise to the mixed solution in step (2), and keep stirring for 2h, then wash, centrifuge, and vacuum freeze-dry for 24h;

[0044] (4) The sample obtained in step (3) was placed in a tube furnace, and the temperature was raised to 350 °C at a rate of 5 °C / min, and kept for 2 h to obtain a NiO / MXene composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com