Preparation method of self-cleaning coating and self-cleaning glass

A self-cleaning and coating technology, used in polyether coatings, coatings, etc., can solve problems such as being unsuitable for large-scale processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

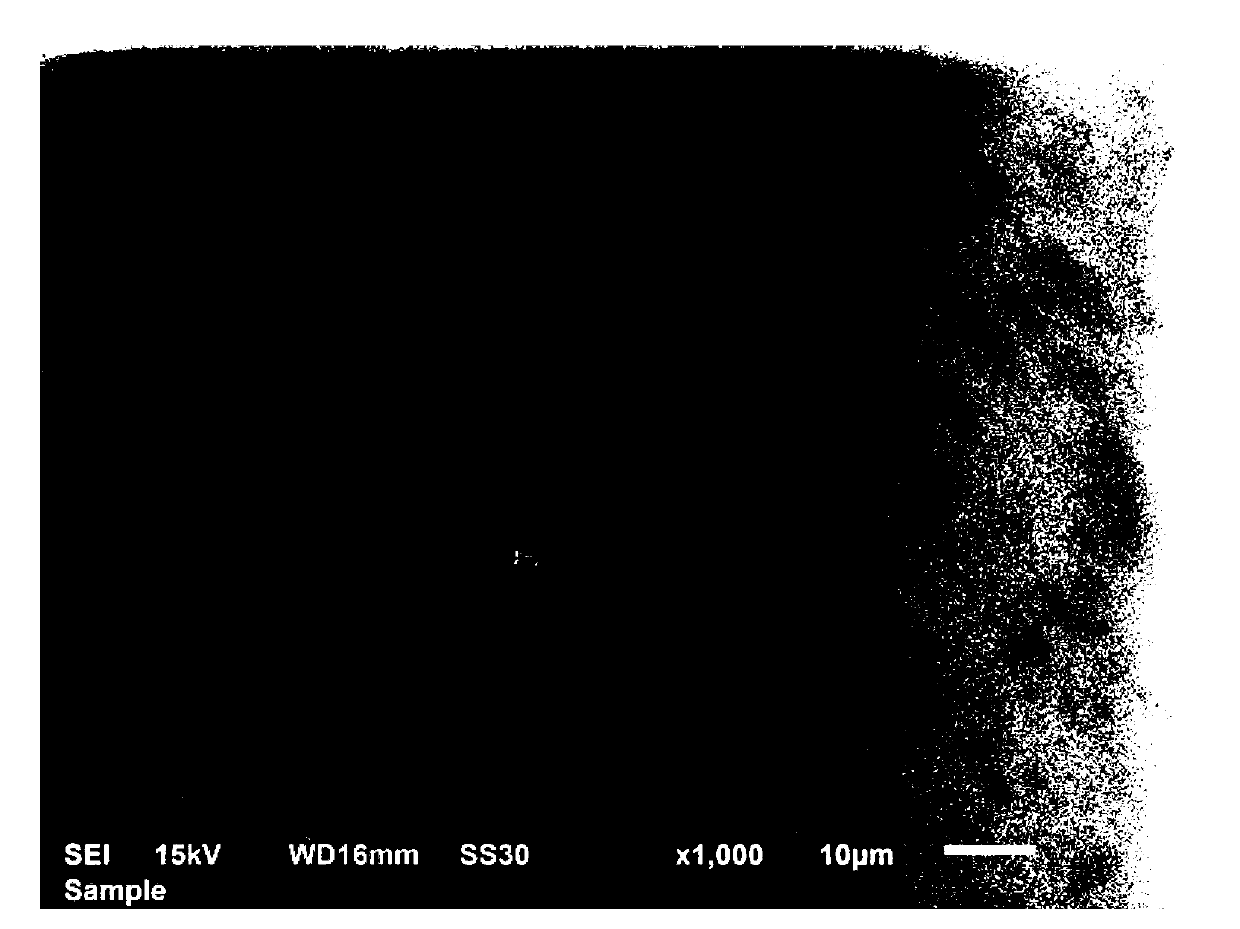

Image

Examples

Embodiment 1

[0029] The preparation process of the self-cleaning coating and the self-cleaning curtain wall glass of this embodiment mainly includes the following steps:

[0030] 1) Preparation of SiO 2 Sol: use anhydrous methanol as solvent and ammonia as catalyst to prepare SiO 2 Sol; SiO 2 The concentration is 0.1-0.5mol / L, the specific steps are as follows:

[0031] 1-1) Take 40ml of anhydrous methanol and add it to a clean beaker, then add 4ml of tetraethyl orthosilicate to it and mix well, seal the mouth of the beaker while stirring, and use it as liquid A, and the stirring time is 0.5h;

[0032] 1-2) Take 80ml of anhydrous methanol and add it to a clean beaker, then add 2ml of concentrated ammonia water to it, mix and stir evenly, seal the mouth of the beaker while stirring, and use it as liquid B, and the stirring time is 0.5h;

[0033] 1-3) Add liquid B dropwise into liquid A with a separatory funnel, and mix while stirring. After the mixing is completed, seal it well and stir ...

Embodiment 2

[0041] The preparation process of the self-cleaning coating and the self-cleaning curtain wall glass of this embodiment mainly includes the following steps:

[0042] 1) Preparation of SiO 2 Sol: use anhydrous methanol as solvent and ammonia as catalyst to prepare SiO 2 Sol; SiO 2 The concentration is 0.1-0.5mol / L. Specific steps are as follows:

[0043] 1-1) Take 60ml of anhydrous methanol and add it to a clean beaker, then add 4ml tetraethyl orthosilicate to it and mix well, seal the mouth of the beaker while stirring, and use it as liquid A, and the stirring time is 0.5h;

[0044] 1-2) Take 120ml of anhydrous methanol and add it to a clean beaker, then add 2ml of concentrated ammonia water to it, mix and stir evenly, seal the mouth of the beaker while stirring, and use it as liquid B, and the stirring time is 0.5h;

[0045] 1-3) Add liquid B dropwise into liquid A with a separatory funnel, and mix while stirring. After the mixing is completed, seal it well and stir at ro...

Embodiment 3

[0052] The preparation process of the self-cleaning coating and the self-cleaning curtain wall glass of this embodiment mainly includes the following steps:

[0053] 1) Preparation of SiO 2 Sol: use anhydrous methanol as solvent and hydrochloric acid as catalyst to prepare SiO 2 Sol; SiO 2 The concentration is 0.05-0.25mol / L; the specific steps are as follows:

[0054] 1-1) Take 60ml of anhydrous methanol and add it to a clean beaker, then add 4ml tetraethyl orthosilicate to it and mix well, seal the mouth of the beaker while stirring, and use it as liquid A, and the stirring time is 0.5h;

[0055] 1-2) Take 120ml of anhydrous methanol and add it to a clean beaker, then add 2ml of concentrated ammonia water to it, mix and stir evenly, seal the mouth of the beaker while stirring, and use it as liquid B, and the stirring time is 0.5h;

[0056] 1-3) Add liquid B dropwise into liquid A with a separatory funnel, and mix while stirring. After the mixing is completed, seal it well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com