Preparation method of prussian blue type energy storage material

An energy storage material, the technology of Prussian blue, which is applied in the field of preparation of Prussian blue energy storage materials, can solve the problems of low yield and achieve the effects of simplifying the production process, shortening the production time and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

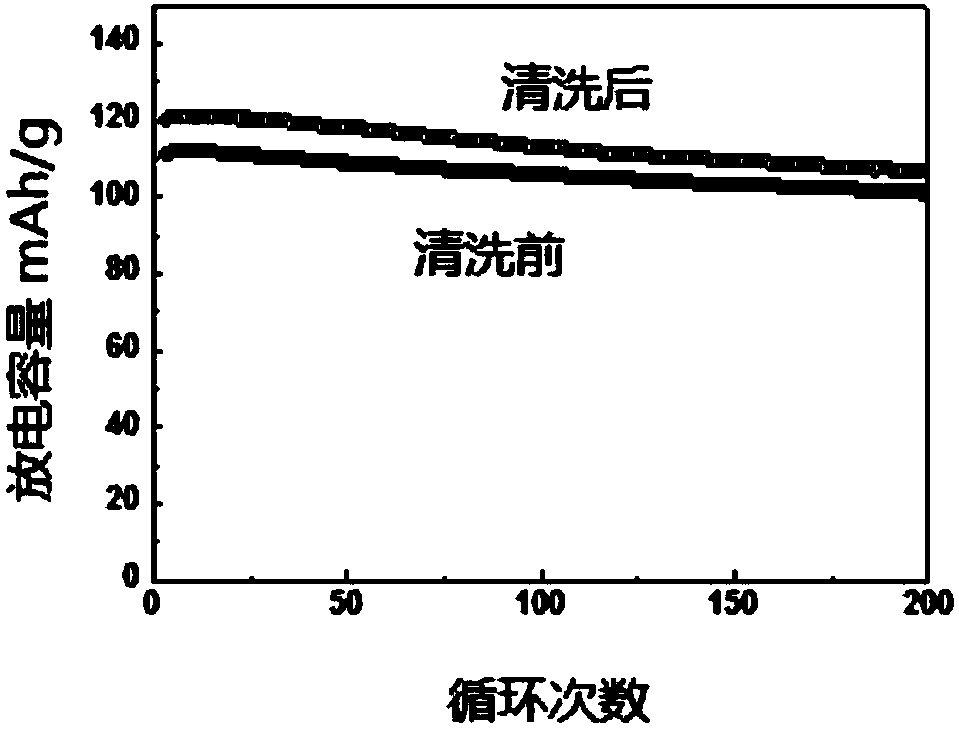

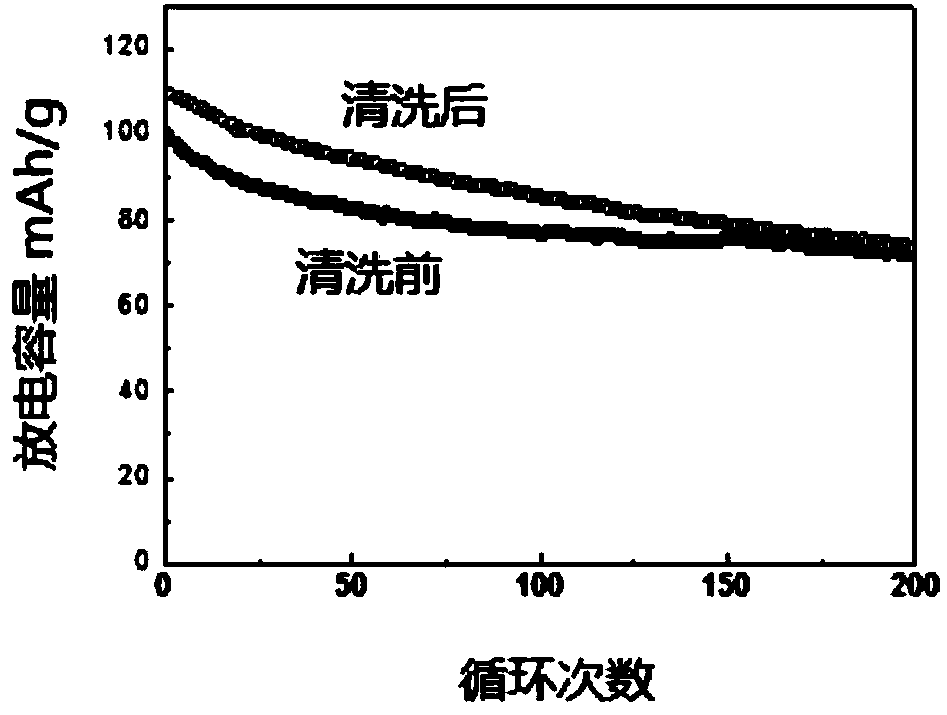

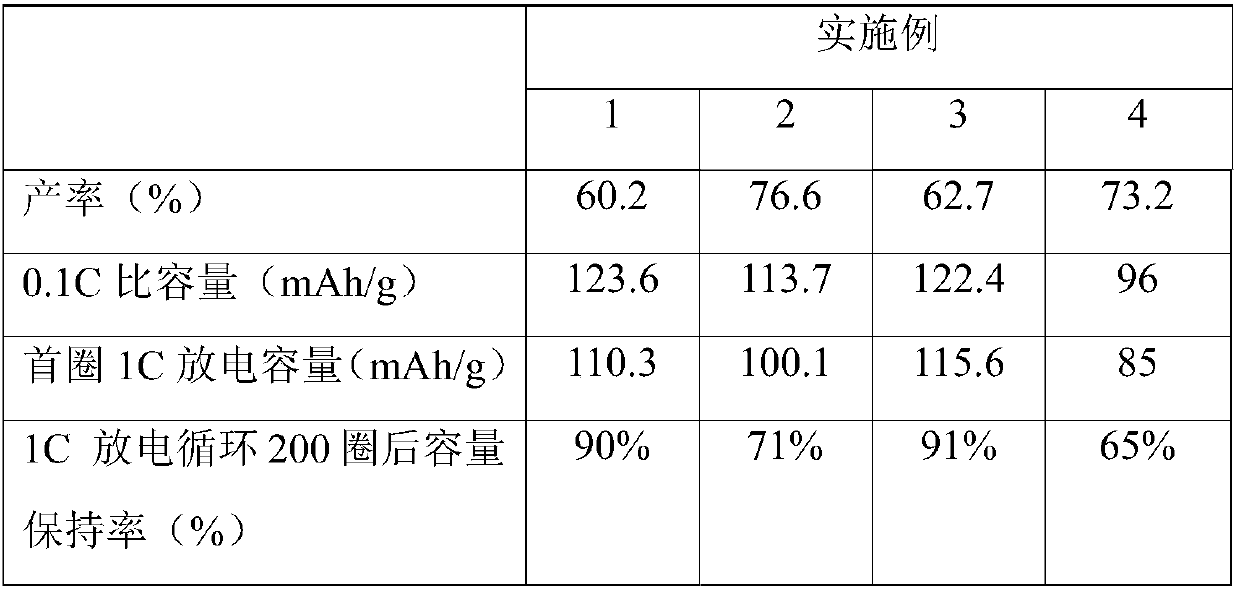

Examples

Embodiment 1

[0033] This embodiment relates to a preparation method of high-yield Prussian blue material sodium ferrocyanide, comprising the following steps:

[0034] (1) Ferrous perchlorate and sodium ferrocyanide are weighed in a mol ratio of 1:1.01, ferrous perchlorate Fe(ClO 4 ) 2 ·6H 2 The mass of O is 3.63g, sodium ferrocyanide Na 4 Fe(CN) 6 10H 2 The quality of O is 4.89g, and the ferrous perchlorate and sodium ferrocyanide that weighed are dissolved in the deionized water of 50ml respectively, are mixed with the ferrous perchlorate solution of 0.2mol / L and the ferrous perchlorate solution of 0.202mol / L Sodium ferrocyanide solution.

[0035](2) Weigh 0.05 mol of sodium perchlorate, dissolve it in 200 ml of deionized water, and prepare a 0.25 mol / L sodium perchlorate solution.

[0036] (3) Heat the three solutions in a temperature-controlled magnetic stirrer water bath, set the temperature at 60°C, and pour the prepared ferrous perchlorate solution and sodium ferrocyanide solut...

Embodiment 2

[0041] This embodiment relates to a preparation method of high-yield Prussian blue material sodium manganese ferrocyanide, comprising the following steps:

[0042] (1) Manganese perchlorate and sodium ferrocyanide are weighed in a mol ratio of 1:1.01, manganese perchlorate Mn(ClO 4 ) 2 ·6H 2 The mass of O is 3.62g, sodium ferrocyanide Na 4 Fe(CN) 6 10H 2 The quality of O is 4.89g, and the manganese perchlorate and sodium ferrocyanide that weighed are dissolved in the deionized water of 50ml respectively, are mixed with the manganese perchlorate solution of 0.2mol / L and the ferrous iron of 0.202mol / L Sodium cyanide solution.

[0043] (2) Weigh 0.025 mol of sodium perchlorate, dissolve it in 200 ml of deionized water, and prepare a 0.125 mol / L sodium perchlorate solution.

[0044] (3) Place the three solutions in a temperature-controlled magnetic stirrer for heating in a water bath, set the temperature to 60°C, and drop the prepared manganese perchlorate solution and sodiu...

Embodiment 3

[0049] This embodiment relates to a preparation method of high-yield Prussian blue material sodium ferrocyanide, comprising the following steps:

[0050] (1) Ferrous perchlorate and sodium ferrocyanide are weighed in a mol ratio of 1:1.01, ferrous perchlorate Fe(ClO 4 ) 2 ·.6H 2 The mass of O is 3.63g, sodium ferrocyanide Na 4 Fe(CN) 6 10H 2 The quality of O is 4.89g, and ferric perchlorate and sodium ferrocyanide that weighed are dissolved in the deionized water of 50ml respectively, are mixed with the ferric perchlorate solution of 0.2mol / L and the ferrous iron of 0.202mol / L Sodium cyanide solution.

[0051] (2) Weigh 0.01 mol of sodium perchlorate, dissolve it in 100 ml of deionized water, and prepare a 0.1 mol / L sodium perchlorate solution.

[0052] (3) Place the three solutions in a temperature-controlled magnetic stirrer water bath, set the temperature to 0°C, and drop the prepared ferrous perchlorate solution and sodium ferrocyanide solution into the high-speed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com