Method for preparing porous graphite-phase carbon nitride material

A technology of phase carbon nitride and porous graphite, which is applied in the field of preparation of porous graphite phase carbon nitride materials, can solve the problems of inhibiting catalytic activity and small specific surface area, and achieve low-cost raw materials, large specific surface area, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (comparative embodiment) Prepare g-C 3 N 4

[0027] Weigh 5g of melamine and put it into a ceramic crucible (cover the crucible lid), heat up to 500°C in a muffle furnace at 50°C / min, keep it roasted at this temperature for 1h, then quickly heat up to 520°C within 5min, and heat-preserve and roast 1h, cooled and ground to obtain a yellow powder sample.

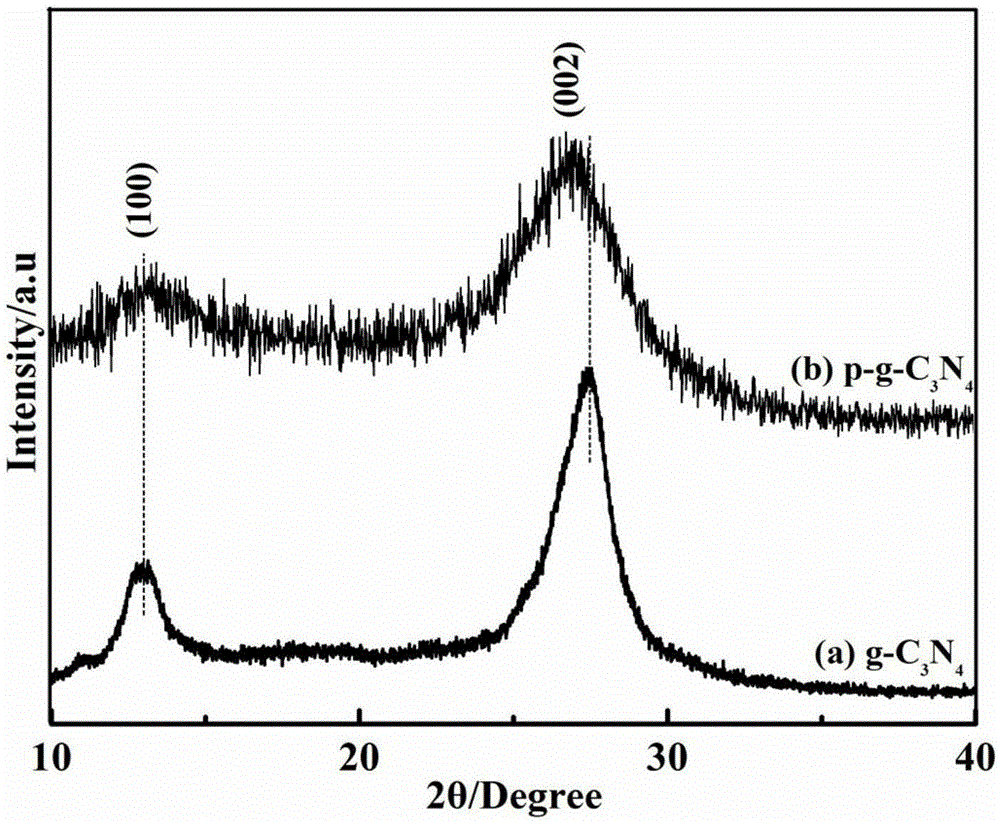

[0028] With the material prepared in Example 1, after X-ray diffractometer scanning, see figure 1 , for g-C 3 N 4 .

Embodiment 2

[0029] Example 2 Preparation of Porous p-g-C 3 N 4

[0030] Such as Figure 6 Shown, a kind of preparation method of porous graphite phase carbon nitride material comprises the following steps:

[0031] (1) Dissolve 20g of melamine in 300ml of deionized water at 80°C, stir for 1.5h, and cool to room temperature;

[0032] (2) Add 20ml of HCl solution with a concentration of 10mol / L dropwise into the solution in step (1), and stir for 1h;

[0033] (3) Dry the mixture obtained in step (2) in an oven at 60°C for 20 hours to obtain a white powder;

[0034] (4) Put the white powder obtained in step (3) into a muffle furnace for calcination. The calcination process is to rapidly raise the temperature to 470°C and keep the temperature for 3 hours; 3 N 4 Material.

[0035] With the material prepared in embodiment 2, after X-ray diffractometer scanning, see figure 1 , prepared p-g-C 3 N 4 and g-C prepared by common method (Example 1) 3 N 4 Same, with graphite-like structur...

Embodiment 3

[0037] Example 3 Preparation of Porous p-g-C 3 N 4

[0038] Such as Figure 6 Shown, a kind of preparation method of porous graphite phase carbon nitride material comprises the following steps:

[0039] (1) Dissolve 40g of melamine in 600ml of deionized water at a temperature of 100°C, stir for 1 hour, and cool to room temperature;

[0040] (2) Add 40ml of HCl solution with a concentration of 12mol / L dropwise into the solution in step (1), and stir for 1h;

[0041] (3) Dry the mixture obtained in step (2) in an oven at 80°C for 12 hours to obtain a white powder;

[0042] (4) Put the white powder obtained in step (3) into a muffle furnace for calcination. The calcination process is to rapidly raise the temperature to 450°C and keep the temperature for 4 hours; 3 N 4 Material.

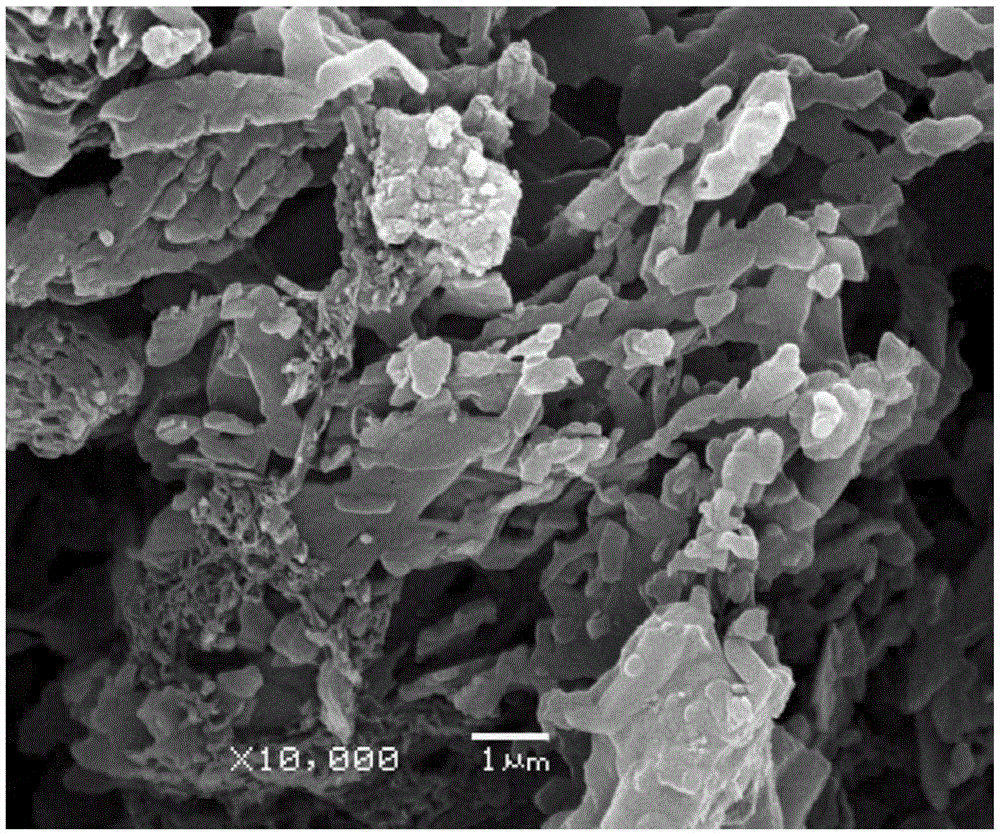

[0043] The p-g-C prepared in embodiment 3 3 N 4 material, observed by scanning electron microscopy, see image 3 , the prepared material is p-g-C with both layered structure and pore structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com