Carbon fiber reinforced zirconium carbide composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of preparation of ultra-high temperature thermal protection structures, can solve the problems of inability to obtain high ZrC content, long preparation cycle of composite materials, low ZrC introduction efficiency, etc., so as to shorten the preparation cycle, improve the introduction efficiency, High density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

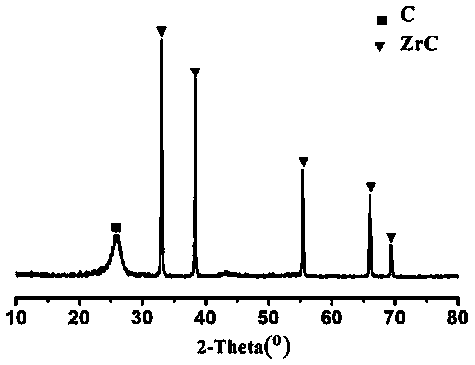

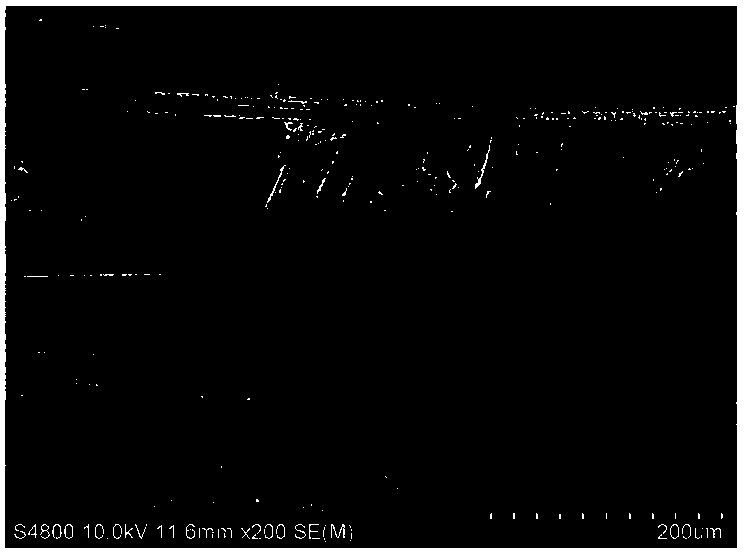

Embodiment 1

[0048] A carbon fiber-reinforced zirconium carbide composite material of the present invention, the carbon fiber-reinforced zirconium carbide composite material uses three-dimensional punctured carbon fiber cloth as a reinforcement, and zirconium carbide as a matrix. In the carbon fiber reinforced zirconium carbide composite material, the volume fraction of ZrC is 28.3%, and the volume fraction of three-dimensional punctured carbon fiber cloth is 45%. The density of the carbon fiber reinforced zirconium carbide composite is 2.10g / cm 3 , The porosity is 8.5%.

[0049] A preparation method of the carbon fiber reinforced zirconium carbide composite material of the above-mentioned present embodiment, comprising the following steps:

[0050] (1) Forming of prefabricated parts: carbon fiber cloth is laminated to make carbon fiber prefabricated parts by puncturing.

[0051] (2) Preparation of fiber coating: using propylene as the precursor, depositing at 1000 °C for 10 h by chemica...

Embodiment 2

[0068] A carbon fiber reinforced zirconium carbide composite material of the present invention, the carbon fiber reinforced zirconium carbide composite material uses zirconium carbide as a matrix and three-dimensional punctured carbon fiber cloth as a reinforcement. In the carbon fiber reinforced zirconium carbide composite material, the volume fraction of three-dimensional punctured carbon fiber cloth is 45%, and the volume fraction of ZrC is 27.2%. The density of the carbon fiber reinforced zirconium carbide composite is 2.05g / cm 3 , The porosity is 8.5%.

[0069] A preparation method of the carbon fiber reinforced zirconium carbide composite material of the above-mentioned present embodiment, comprising the following steps:

[0070] (1) Forming of prefabricated parts: carbon fiber cloth is laminated to make carbon fiber prefabricated parts by puncturing.

[0071] (2) Preparation of fiber coating: Deposit a cracked carbon coating on the surface of the fiber of the carbon f...

Embodiment 3

[0081] A carbon fiber reinforced zirconium carbide composite material of the present invention, the carbon fiber reinforced zirconium carbide composite material uses zirconium carbide as a matrix and three-dimensional punctured carbon fiber cloth as a reinforcement. In the carbon fiber reinforced zirconium carbide composite material, the volume fraction of three-dimensional punctured carbon fiber cloth is 45%, and the volume fraction of ZrC is 30.7%. The density of the carbon fiber reinforced zirconium carbide composite is 2.21g / cm 3 , The opening rate is 6.2%.

[0082] A preparation method of the carbon fiber reinforced zirconium carbide composite material of the above-mentioned present embodiment, comprising the following steps:

[0083] (1) Forming of prefabricated parts: carbon fiber cloth is laminated to make carbon fiber prefabricated parts by puncturing.

[0084] (2) Preparation of fiber coating: Deposit a cracked carbon coating on the surface of the fiber of the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com