Ring joint and fixed pull force cracking leather cylinder for material distribution belt machine

A belt conveyor and leather tube technology, which is applied in the field of loop connection and constant tension cracking leather tube, can solve the problems of inability to meet the needs of use, large height difference, hidden safety hazards of material blocking and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

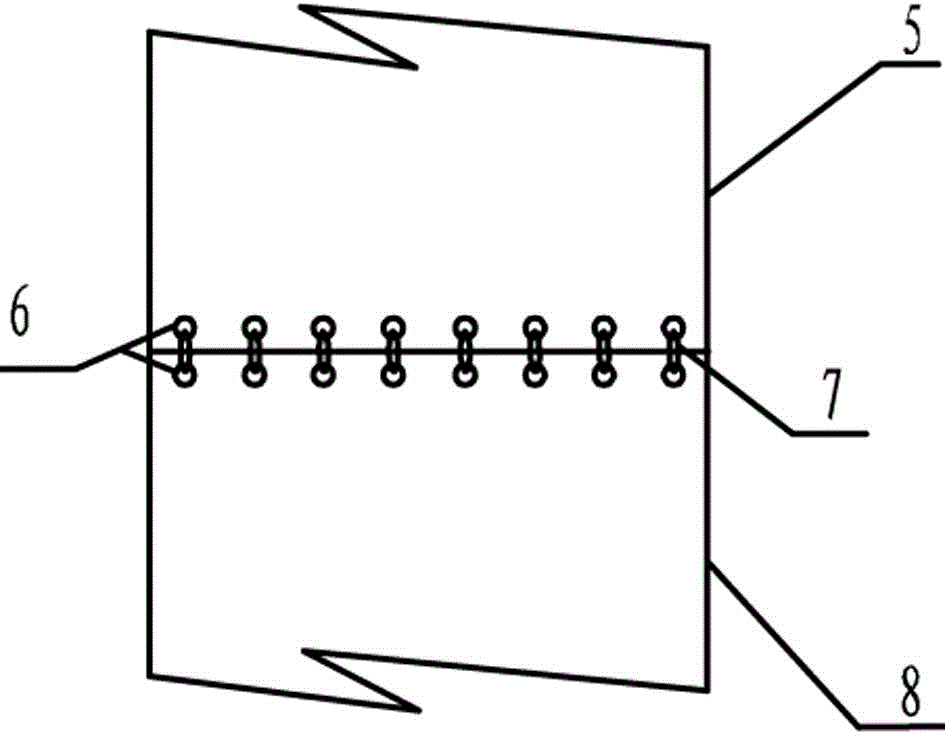

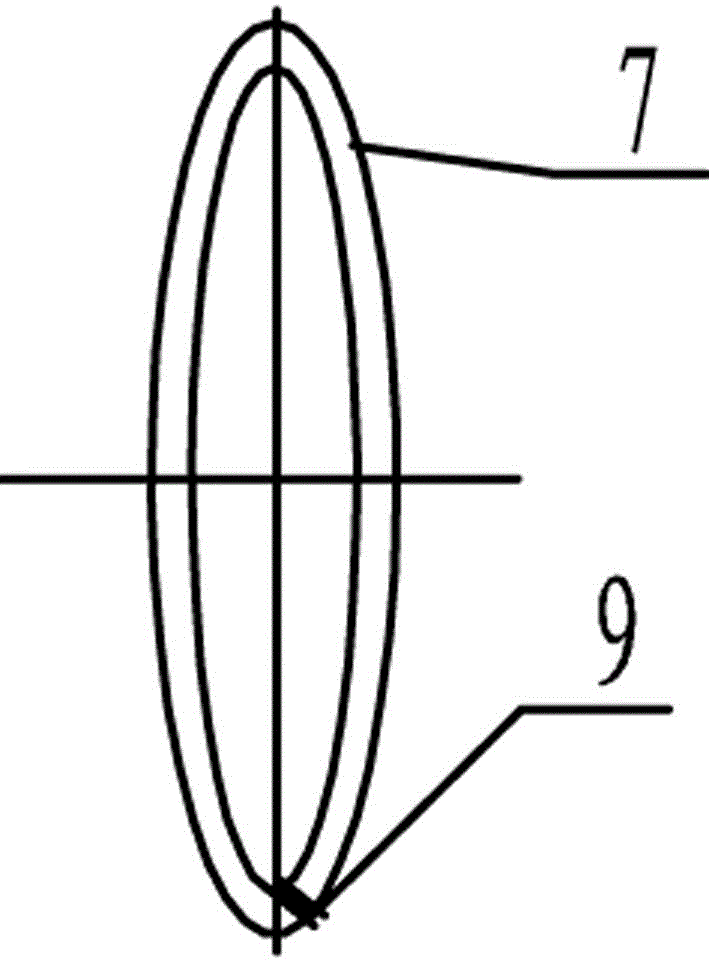

[0014] The structure of the present invention is as figure 2 and 3 As shown, a cloth belt conveyor ring connection, constant tension cracking type leather tube, the leather tube includes the upper section of the leather tube 5 and the lower section of the leather tube 8, the upper section of the leather tube 5 and the lower section of the leather tube 8 are provided with a leather tube port Pull rings 6 are provided with constant tension cracking rings 7 between the pull rings 6 at the port of the leather tube. Fixed tension cracking ring 7 is provided with invisible breach 9.

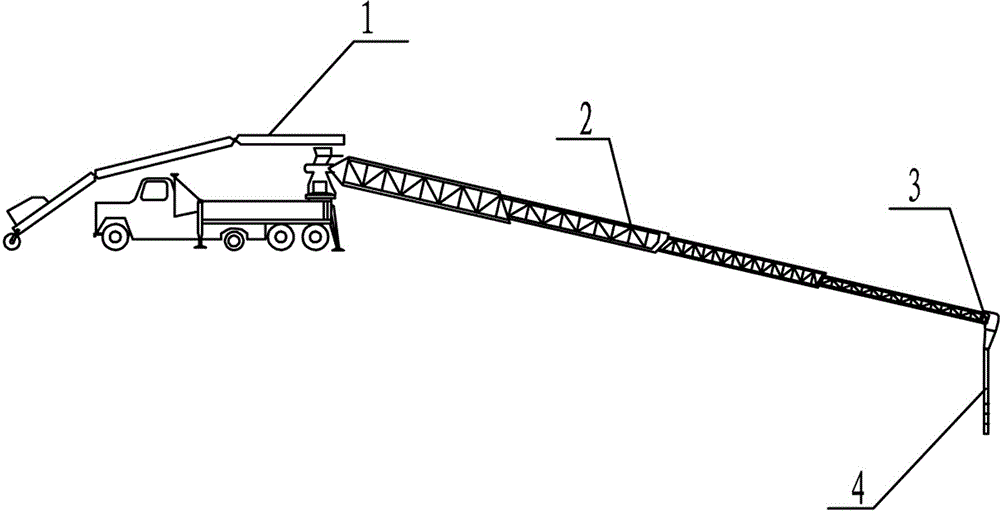

[0015] figure 1 It is a diagram of the equipment components of the placing machine. The placing machine 1 is responsible for conveying concrete to the concrete pouring equipment at the pouring site. Equipment such as tire belt machine and tower belt machine have similar functions; The slewing and the stretching of the conveying belt conveyor cover the pouring area; 3 is the overload torque alarm, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com