Gas smelting furnace and smelting method using gas

A gas smelting furnace and smelting furnace technology, which is applied in the field of smelting and gas smelting furnaces using gas, can solve the problems of inability to open molten iron holes, slow melting materials, melting of pillars, etc. The effect of lowering and reasonable nozzle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

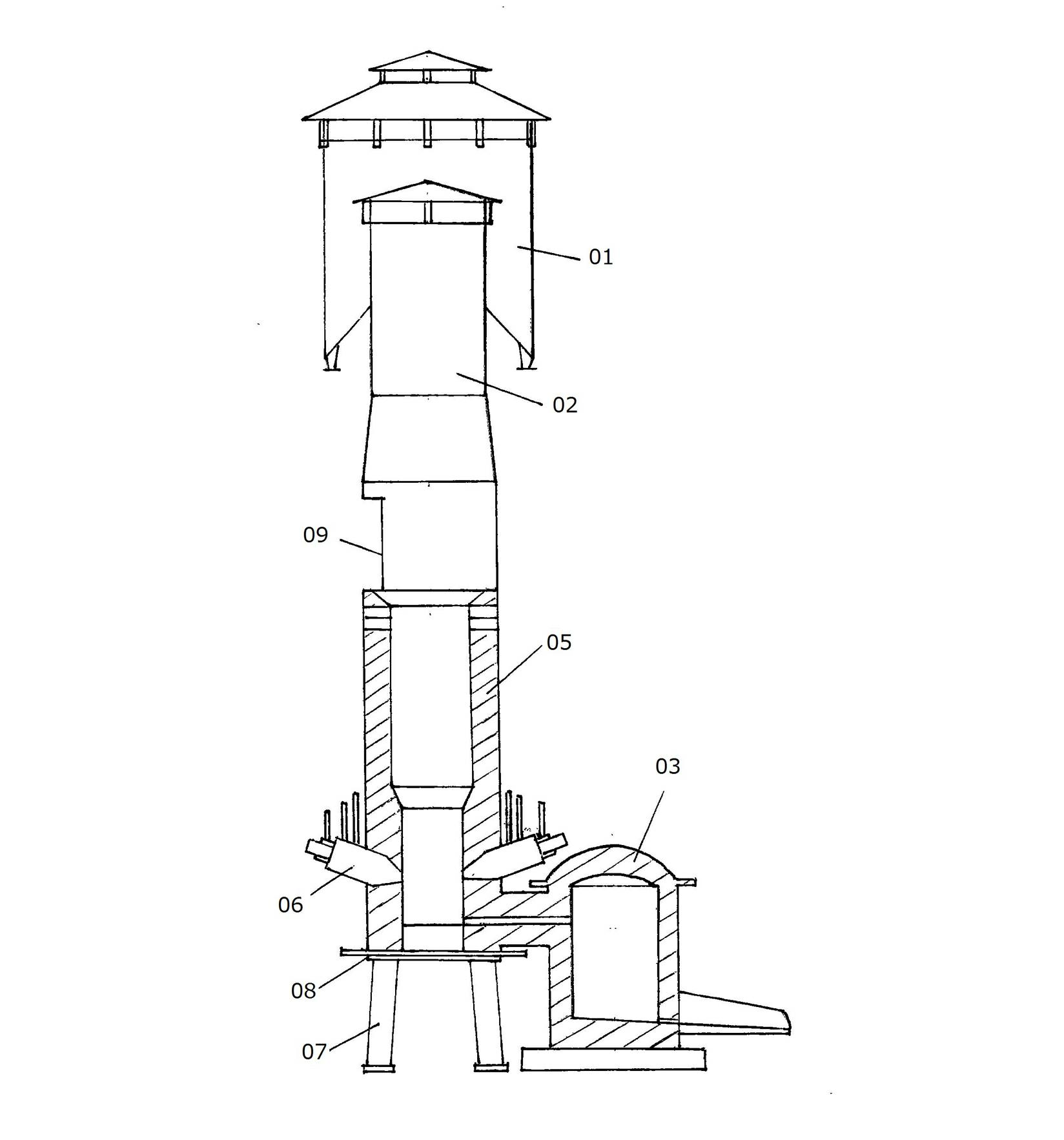

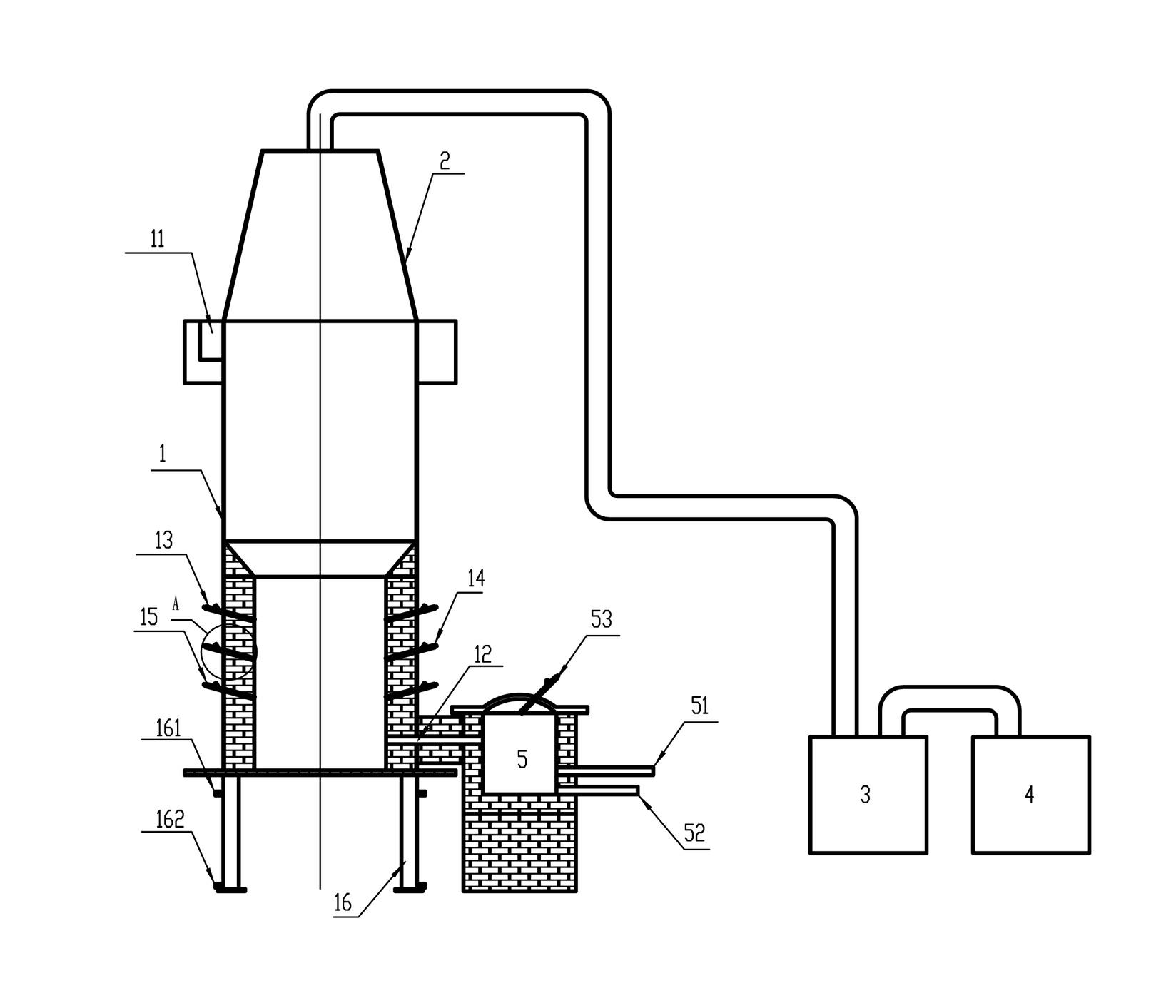

[0028] Such as figure 2 As shown, a kind of gas smelting furnace provided by the present invention comprises a body of furnace 1, the upper end of the body of furnace 1 is connected to a chimney, a spiral dust removal device 2 is set between the body of furnace and the chimney, and an induced draft fan 3 is connected on the chimney, and the chimney The outlet leads into a pool 4. Through the dust removal device and the water pool, the exhaust gas of the melting furnace can be fully purified.

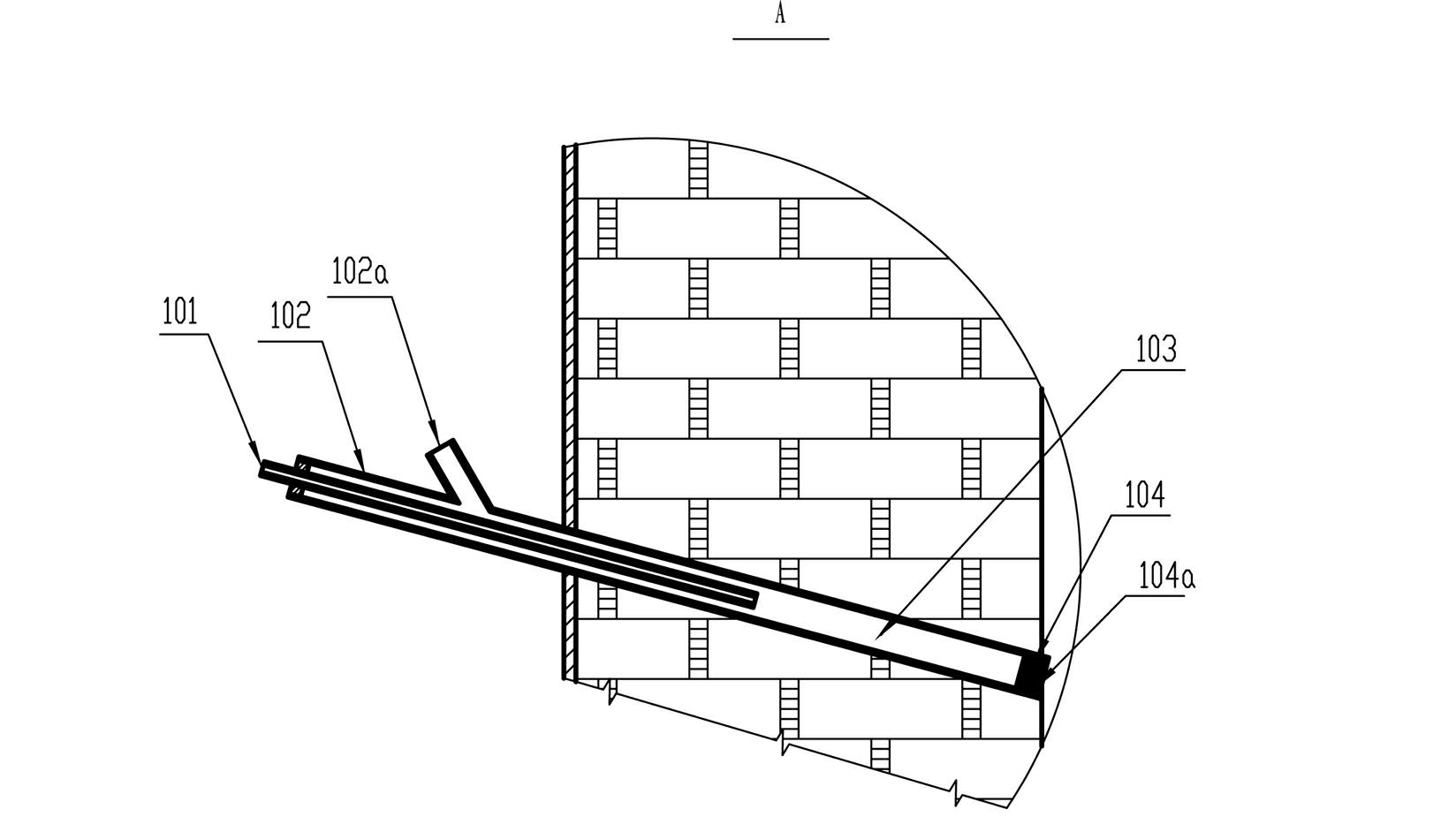

[0029] A feeding port 11 and a molten iron discharge port 12 are arranged on the furnace body 1, and a feeding mechanism is arranged on the feeding port. Between the feed port 11 and the discharge port 12 in the furnace body 1, at least two rows of gas and combustion-supporting gas nozzles surrounding the side wall of the furnace body are arranged from top to bottom; At the set height of the furnace body, this position is the melting section of the smelting furnace. The nozzles here c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com