High-temperature formwork turning clamp

A mold shell, high temperature technology, applied in casting molding equipment, molds, cores and other directions, can solve the problems of rapid temperature drop of mold shell, easy burns of high temperature mold shell, time-consuming and other problems, and achieves reduction of casting defects, compact structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

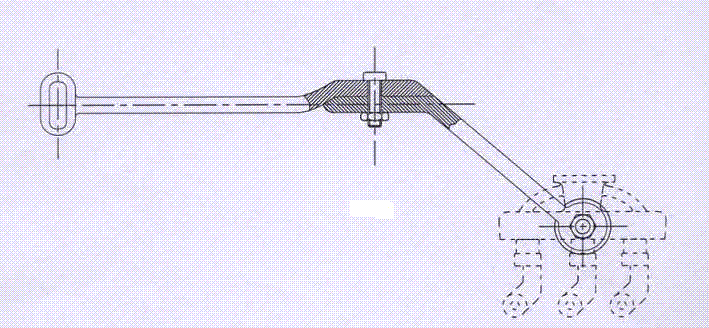

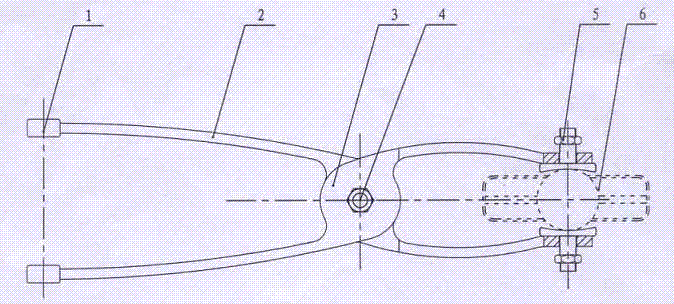

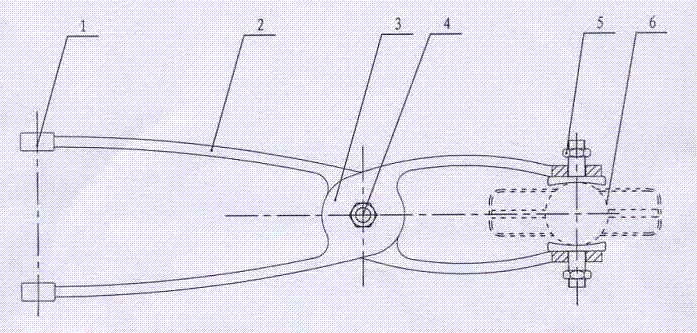

[0008] The present invention demonstrates the implementation mode through its working principle. When in use, the operator holds the tong handle 1 with both hands, separates the jaws 5, and clamps the red upright formwork 6 on the roasting furnace table, and the center of gravity of the formwork 6 changes when it is lifted up and transported. Turn it over by itself, let the bottom of the shell fall on the sand table, and arrange the sprues upwards to be poured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com