A kind of concrete engineering construction technology

A technology of engineering construction and technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of slow construction efficiency and many screws, and achieve easy transportation and reduce Volume, surface quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

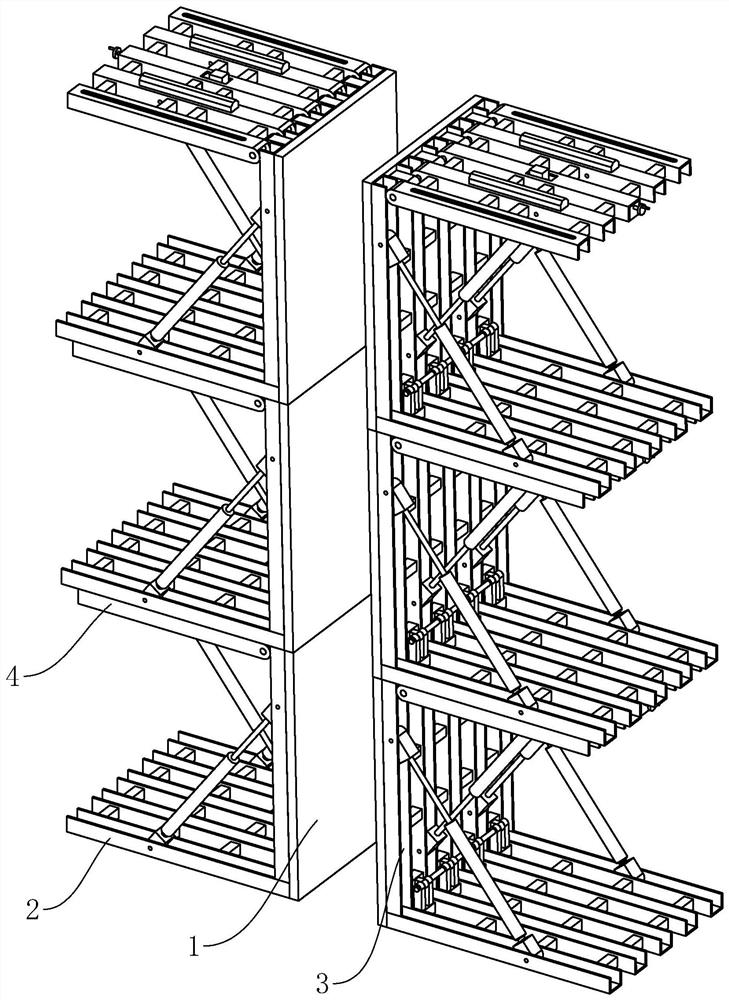

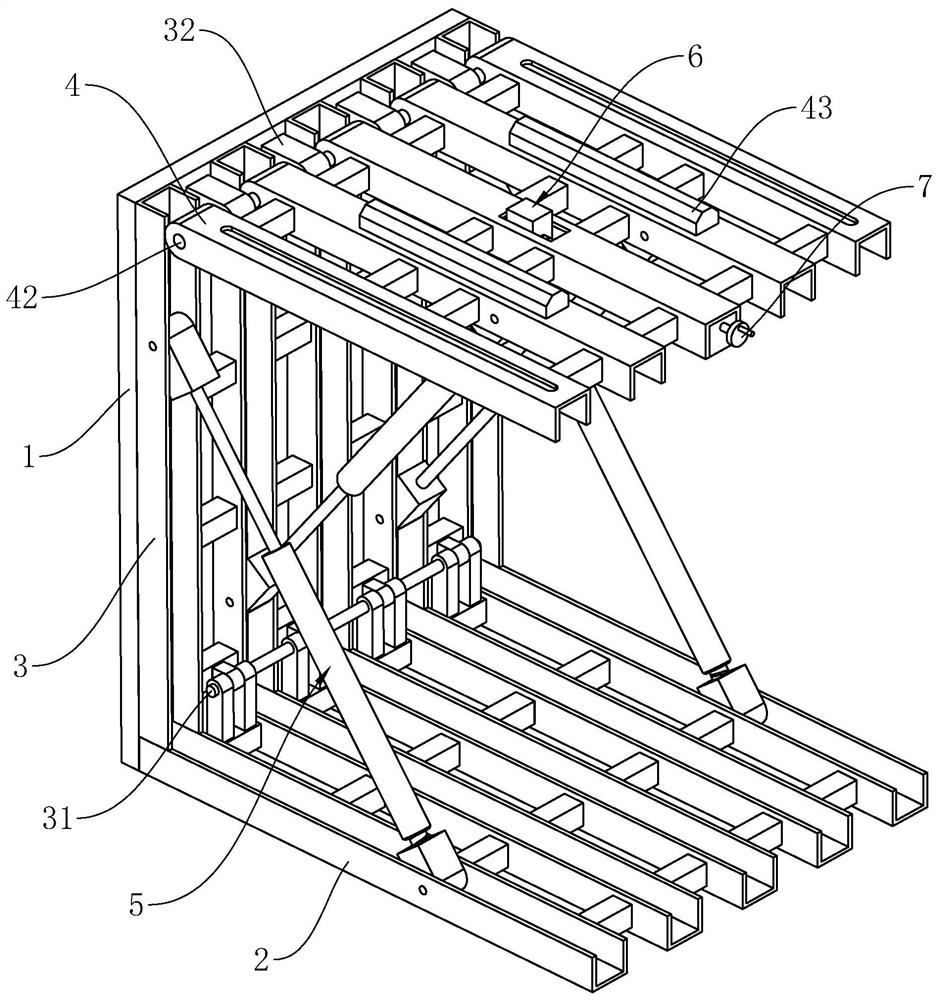

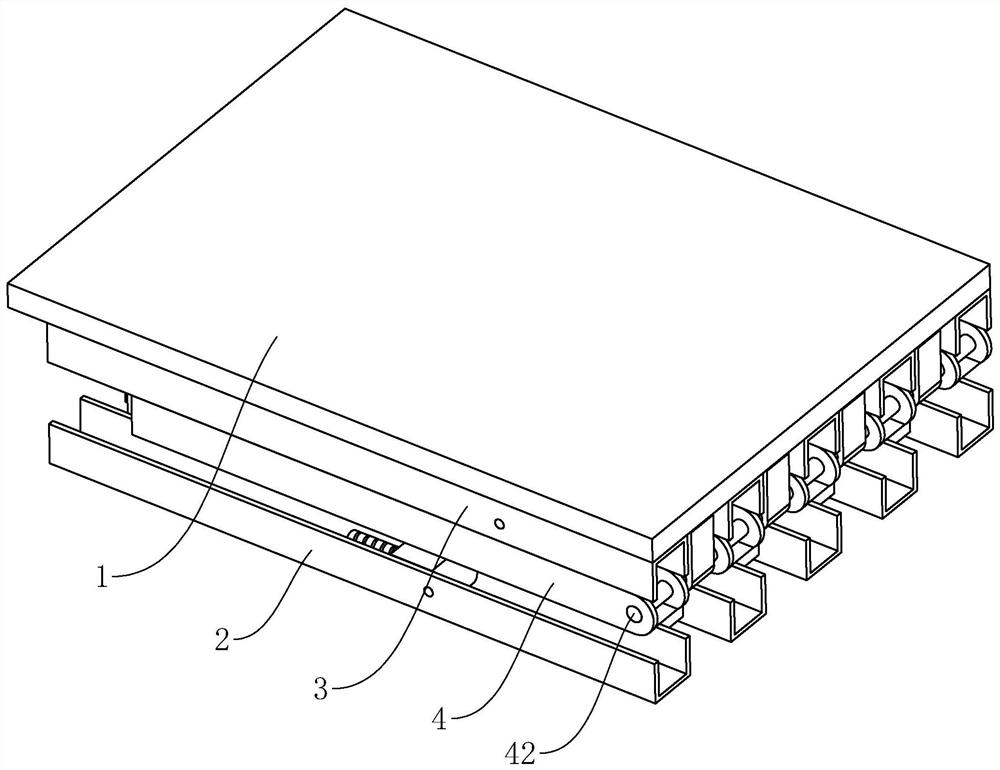

[0042] The following is attached Figure 1-8 The application is described in further detail.

[0043] The embodiment of the application discloses a concrete engineering construction process, and its construction steps are as follows:

[0044] S1. Prepare the raw material of the steel bar, first use the steel bar straightening machine to straighten the steel bar and then cut the steel bar to ensure the high accuracy of the length after cutting; then wire the end of the steel bar that needs to be connected, and use bending The machine bends the steel bar that needs to be bent, and makes the stirrup at the same time; then insert the stirrup on the main bar according to the design requirements, or use the method of inserting the main bar into the stirrup to ensure that the stirrup is perpendicular to the main bar, and then The connection point of the stirrup and the main reinforcement shall be spot welded or bound with iron wire.

[0045] While making the reinforcement cage, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com