Self-propelled diamond pinned truss hanging basket structure and hanging basket walking and construction method

A truss-type, diamond-shaped pin technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of delaying the construction period, hindering the enterprise, and poor replaceable and adjustable capabilities, so as to ensure construction safety and external formwork Stiffness, the effect of solving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the technical solution of the present invention more clearly.

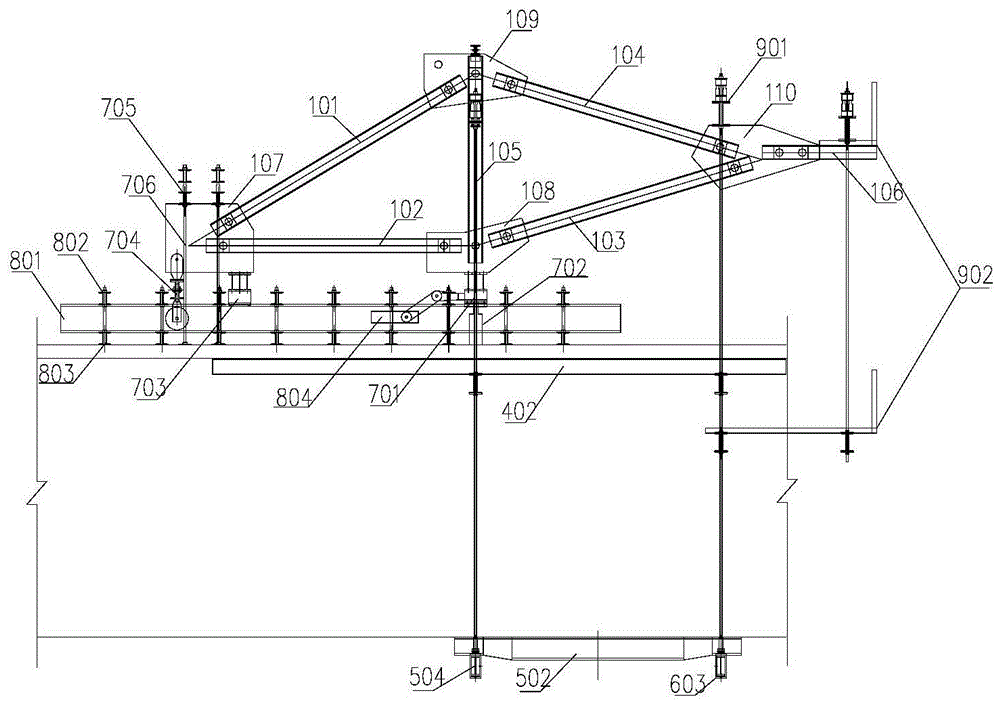

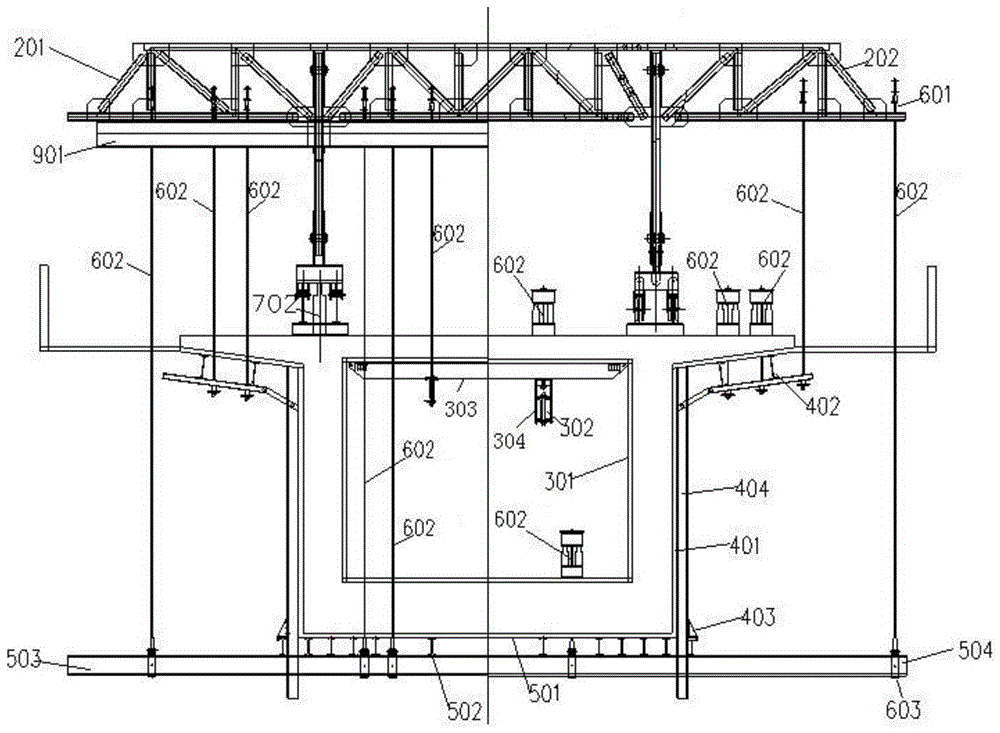

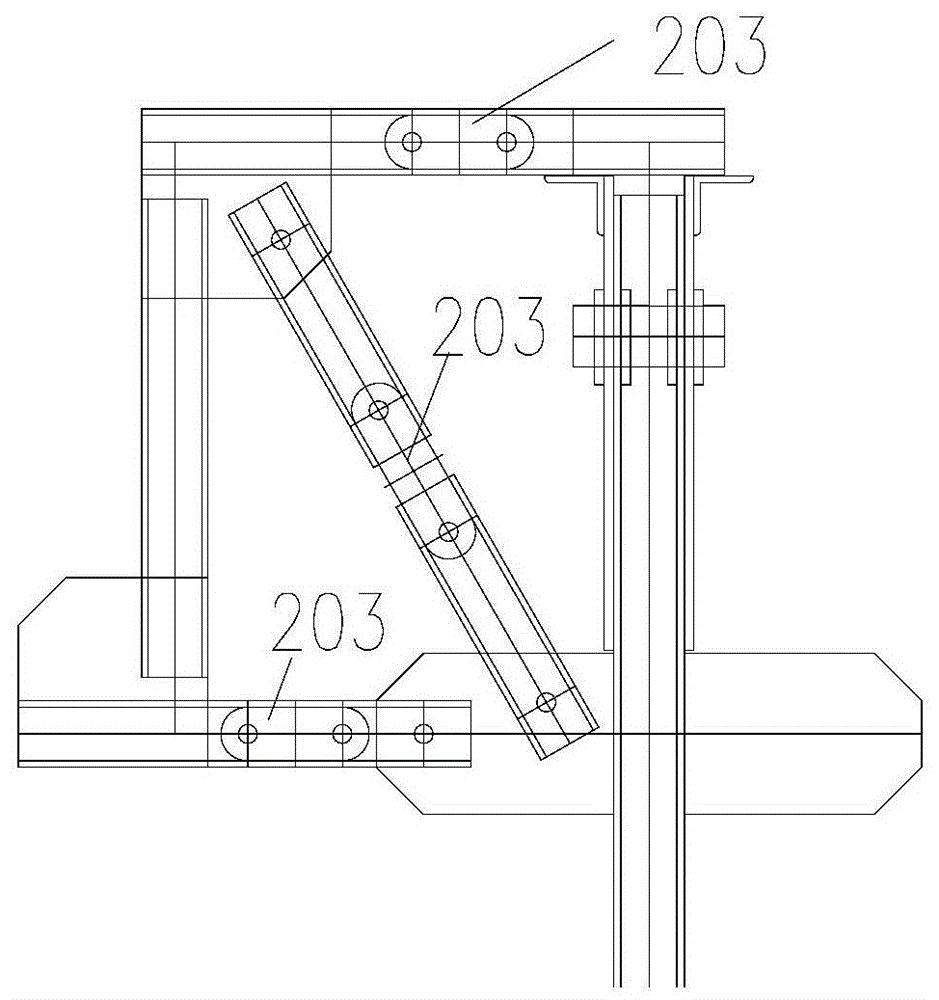

[0055] exist figure 1 , 2In the concrete pouring state shown, the hanging basket is composed of a main truss system, a horizontal parallel connection system, an inner mold system, an outer mold system, a bottom mold platform system, a hanging system, an anchoring system and a running system. Each main truss is generally arranged at the web position of the corresponding cantilever cast box girder, and is formed by connecting diagonal stays 101, lower chords 102, oblique compression rods 103, upper chords 104, vertical rods 105, and cantilever rods 106 by joint boxes. The cross-sectional size of each main truss structure is the same, the transverse end faces of the oblique tie rods 101, oblique compression rods 103, upper chord rods 104, and lower cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com