Method for casting prestressed concrete T beam without shutter vibrator

A vibrator and concrete technology, used in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of residents and units, noise pollution, large vibration and noise of attached vibrators, affecting normal work and life, etc. , to achieve the effect of reducing construction investment, shortening construction period, major economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

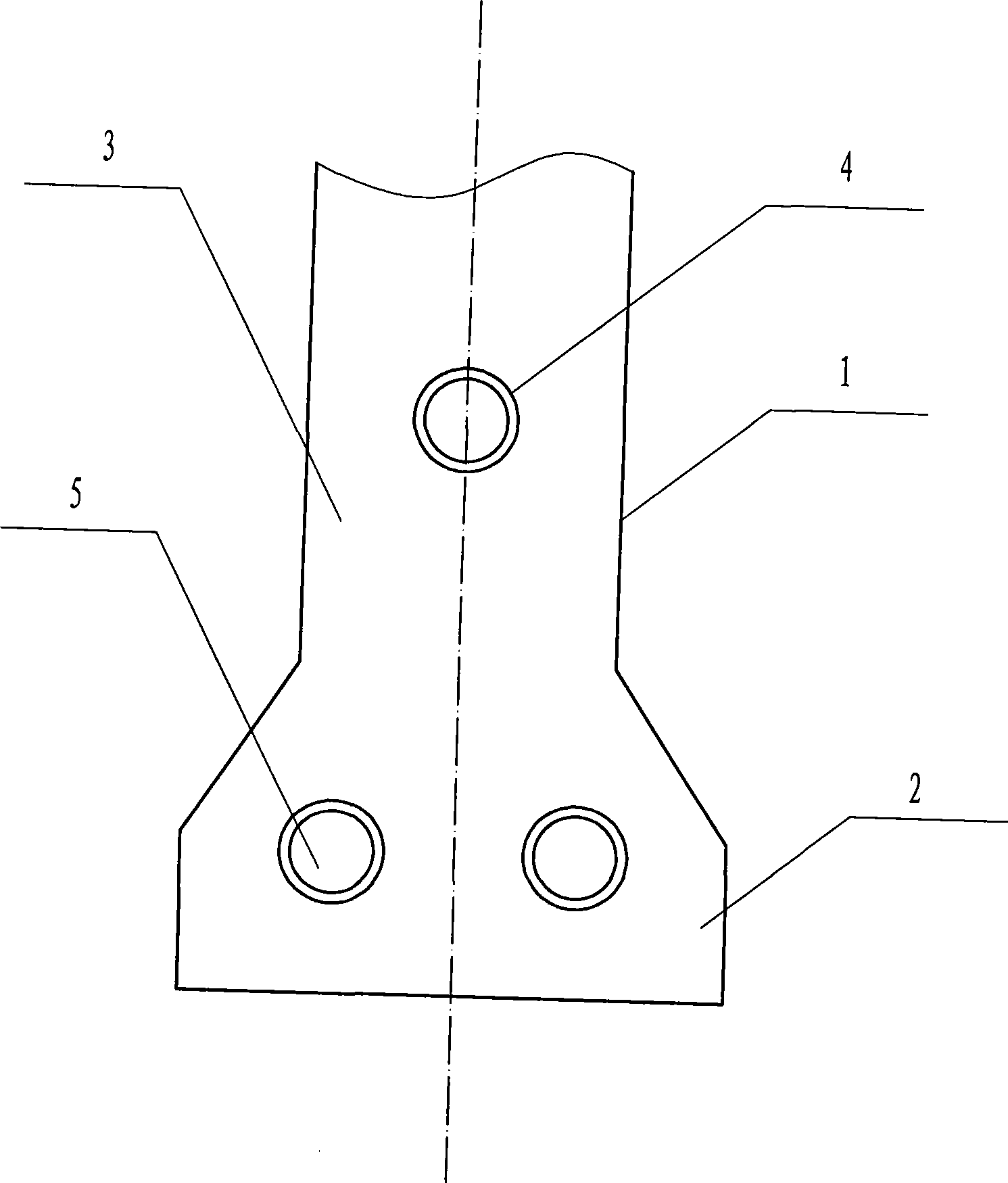

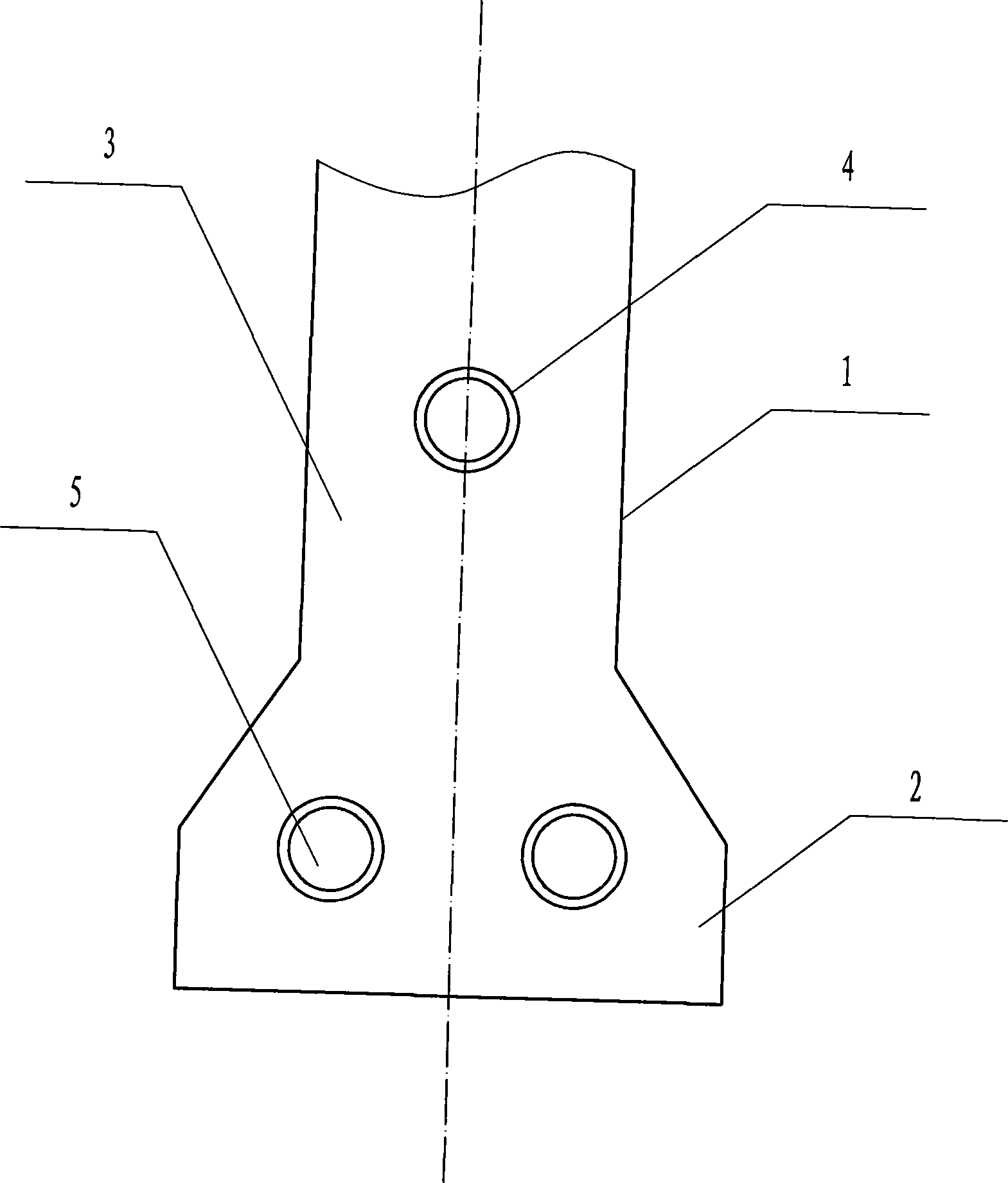

[0022] As shown in Figure 1, 1-T beam body, 2-rib foot, 3-rib plate, 4-corrugated pipe, 5-steel hinge harness;

[0023] The T-beam involved in the present invention includes a T-beam body 1, the T-beam body 1 is in a "T" shape, the lower part of the rib foot 2 is wider, and the width of the upper part of the rib plate 3 is smaller than the width of the rib foot 2; There are bellows 4 arranged through the rib plate 3; according to its structure and the needs of the force, there are usually multiple bellows 4, and four bellows 4 are shown in the figure; inside the bellows 4 are arranged Steel hinge harness5. Certainly, if a concrete top slab approximately parallel to the rib foot 2 is set above the rib 3, the concrete beam of "I" shape has just been formed, and its structure is basically the same or similar to the T-shaped beam structure of the present invention. of.

[0024] The method for pouring prestressed concrete T-shaped girder without attachment type vibrator of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com