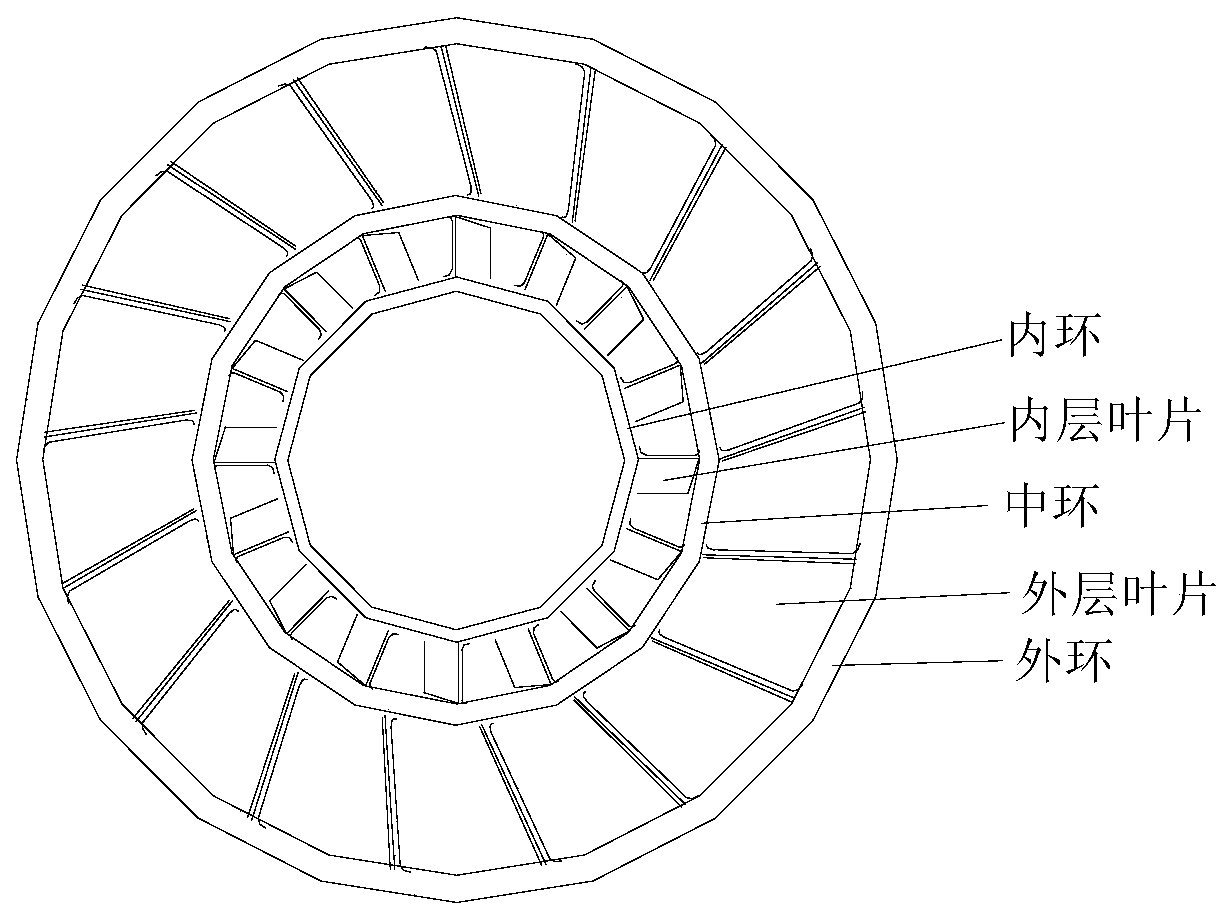

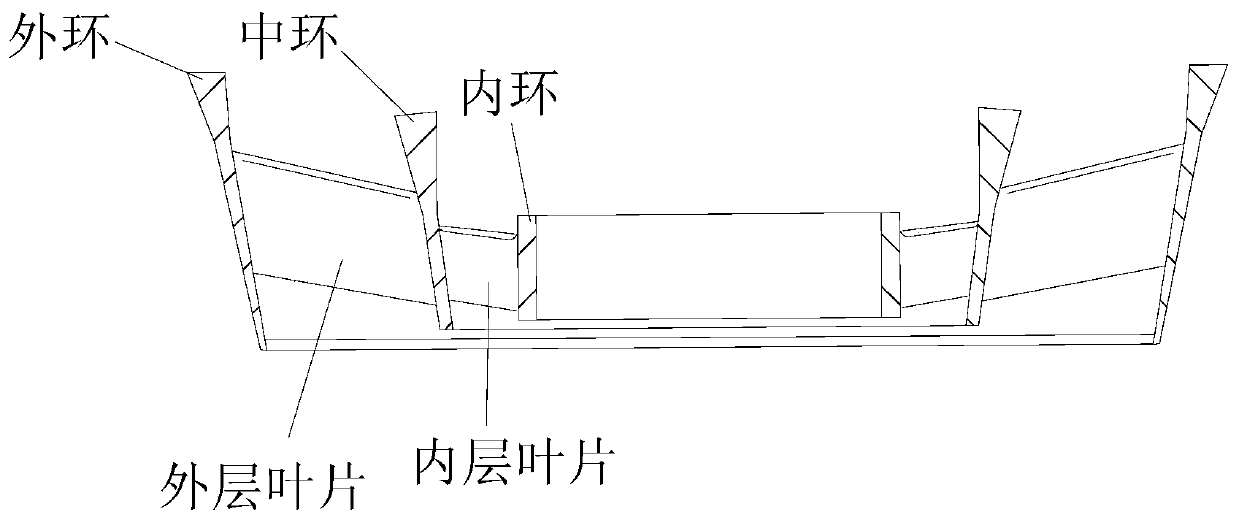

Dynamic balance pouring system of double-layer blade thin-wall guider

A double-layer blade, dynamic balance technology, which is applied in casting molding equipment, molds, cores, etc., can solve the problem of inability to meet the casting requirements of the thin-walled guide of the double-layer blade, reduce the loose scrap rate, and meet the casting requirements. , Improve the effect of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

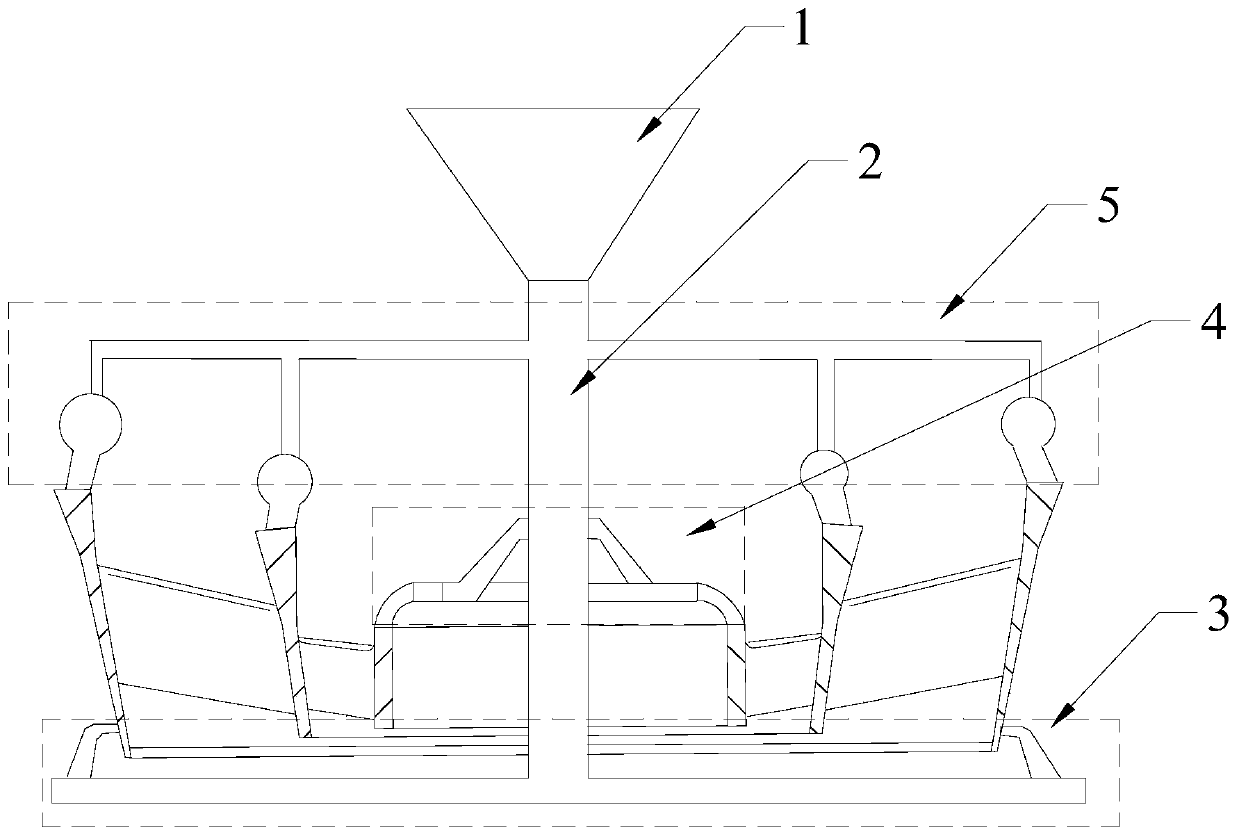

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

[0039] Such as image 3 with Figure 4 As shown, the preferred embodiment of the present invention provides a dynamic balanced pouring system for a double-blade thin-walled guide, and the shell of the double-blade thin-walled guide has at least One ring is provided with a riser, and the dynamic equilibrium gating system includes a sprue cup 1 for pouring and draining molten alloy liquid and retaining slag, and a straight line connected with the sprue cup 1 for vertical drainage of molten alloy liquid. Runner 2. The dynamic balance gating system also includes three layers of runners respectively connected to the sprue 2 and arranged up and down in sequence, wherein the first layer of runners 3 located at the bottom is used to transfer the sprue 2 from the sprue 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com