Novel electric pole feeder

A feeder and pole technology, applied in the field of feeders, can solve the problems of low efficiency of cement poles, simple equipment, short life of the feeder, etc., to achieve labor-saving and efficient pouring, avoid time-consuming and laborious, and protect the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

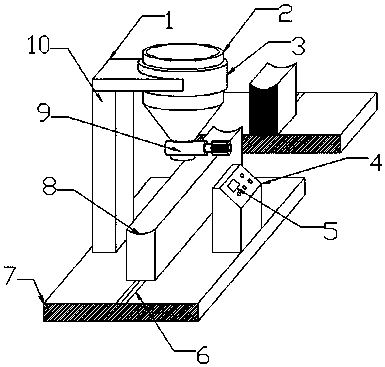

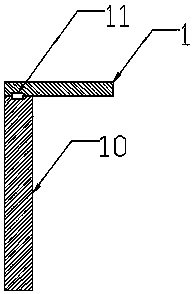

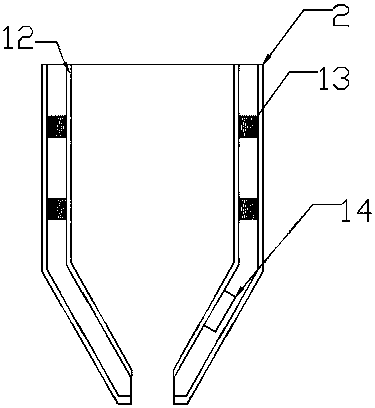

[0016] Such as Figure 1-3 Shown: a new pole feeder, including a base 7 and an outer bucket 2, a track 6 is provided in the middle of the top of the base 7, a mold fixing table 8 is provided on the track 6, and a control box 4 is provided on one side of the track 6 , the control box 4 is embedded with a weight transmitter 5, the weight transmitter 5 is electrically connected to an external power supply, the other side of the track 6 is fixed with a second fixed plate 10, and the top of the second fixed plate 10 is provided with a second A fixed plate 1, a weight sensor 11 is arranged between the first fixed plate 1 and the second fixed plate 10, the weight sensor 11 is electrically connected to the weight transmitter 5, and the first fixed plate 1 is far away from the end of the second fixed plate 10 A fixed ring 3 is fixed, and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com