Hazardous waste special container automatic clamping turnover machine

A turning machine and container technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of direct contact between workers and hazardous waste, endangering the physical and mental health of workers, and failure to recycle, so as to reduce disposal costs , saving resources and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

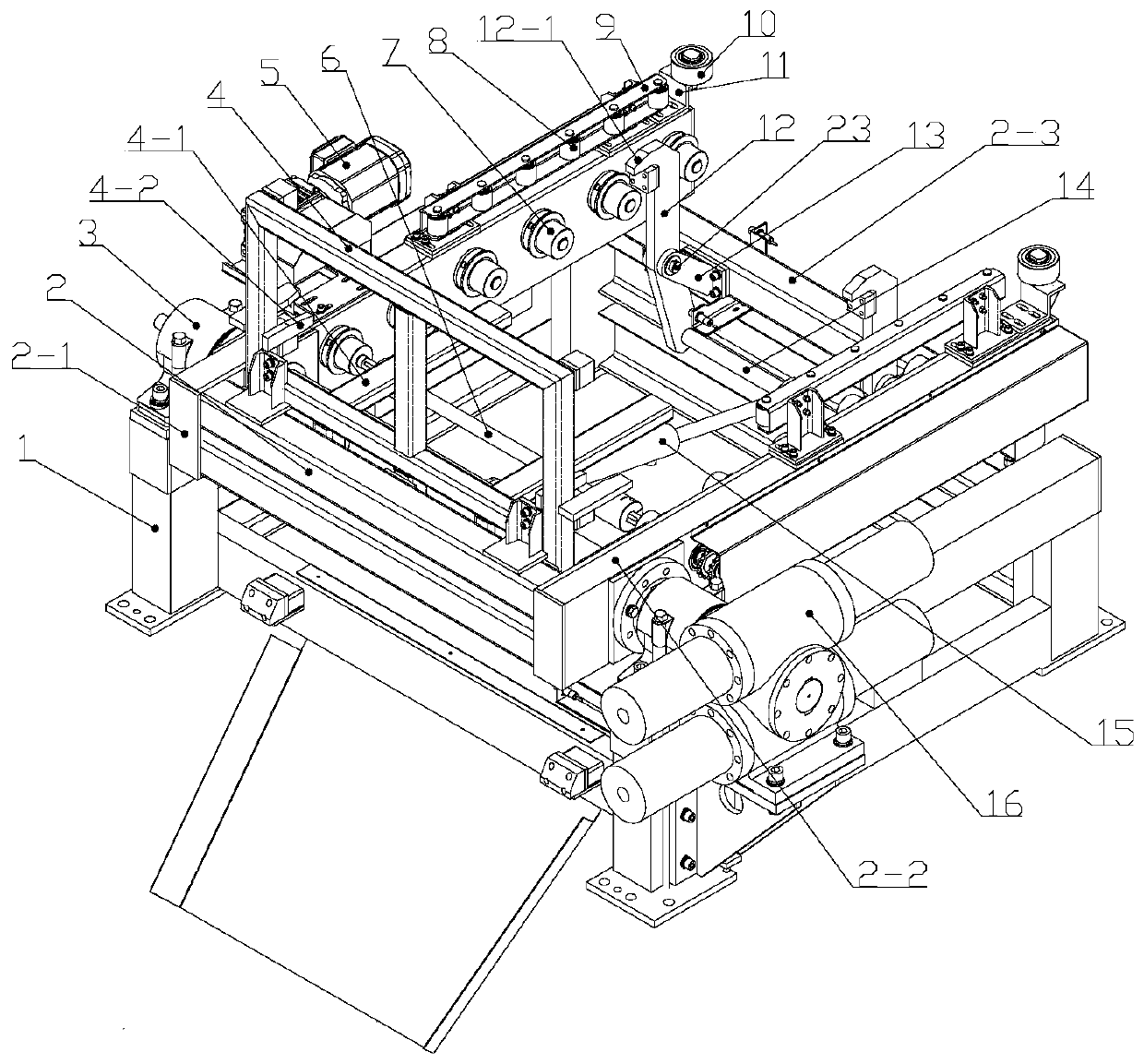

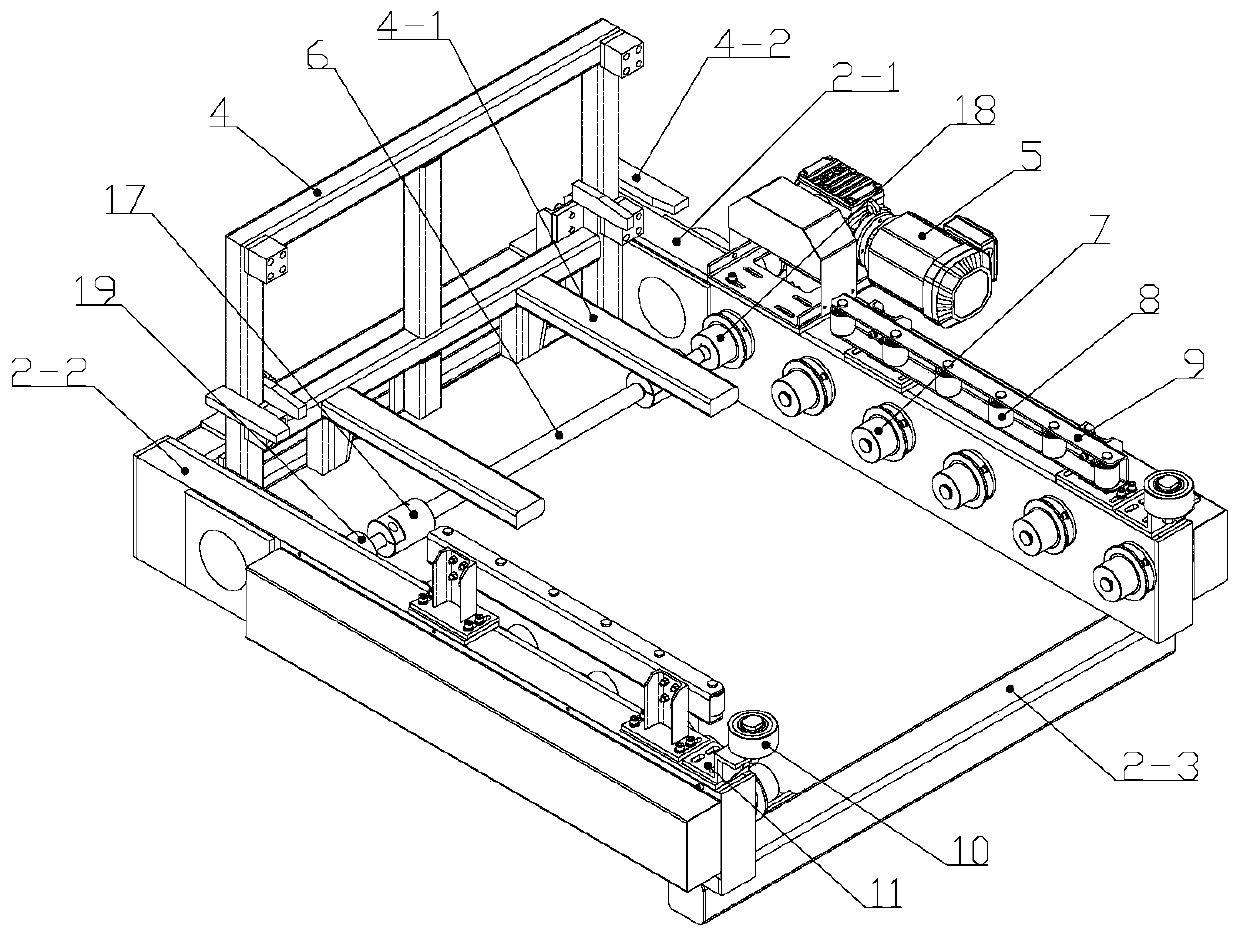

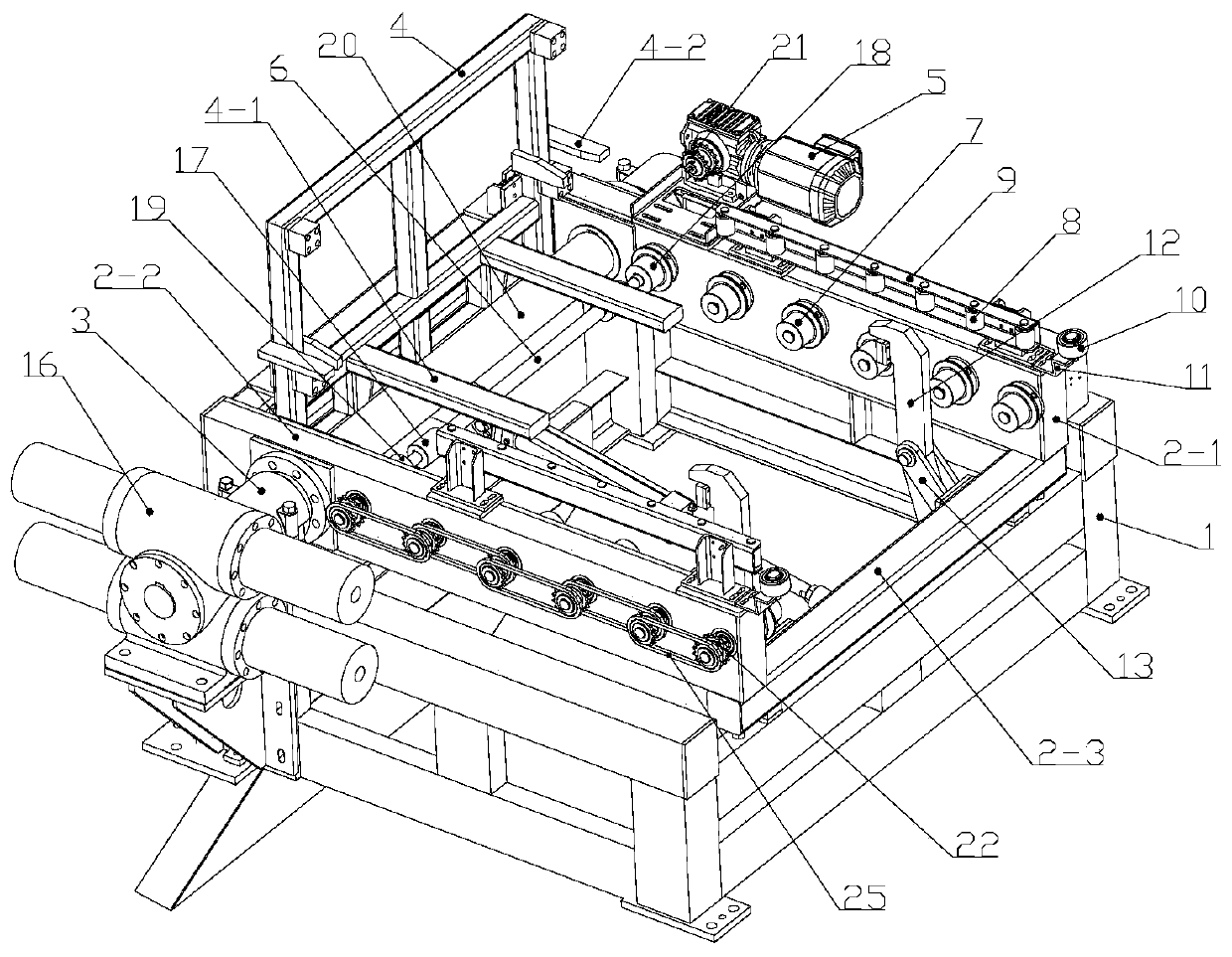

[0032] see Figure 1 to Figure 5 , an automatic clamping and turning machine for special containers for hazardous waste, comprising a base frame 1, the left and right sides of the base frame 1 are respectively provided with rotating shaft support seats 3, and the two rotating shaft support seats 3 jointly support a rotating shaft 20 through bearings. The lower end of the rotating shaft supporting seat 3 is fixedly connected with the longitudinal beam of the base frame 1, and the upper part of the rotating shaft supporting seat 3 is a bearing seat for installing bearings. One end of the rotating shaft 20 is fixedly connected to the output shaft of the swing hydraulic cylinder 16 installed on the base frame 1 in the circumferential direction, and the swing hydraulic cylinder 16 is installed on the mounting bracket provided on the side wall of the base frame 1, and one end of the mounting bracket is downward. The extension is fixed to the base frame 1, and the other end extends h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com