Automatic delivery device for electronic kiln

A kind of kiln and automatic technology, applied in the direction of furnace, furnace components, charge control, etc., can solve the problems of many equipments in use, the utilization rate is only 50%, and the interruption time is long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following in the form of examples, but none of the descriptions to the examples is an explanation of the solutions of the present invention. Any equivalent transformation made according to the concept of the present invention which is merely formal but not substantive shall be regarded as the scope of the technical solution of the present invention.

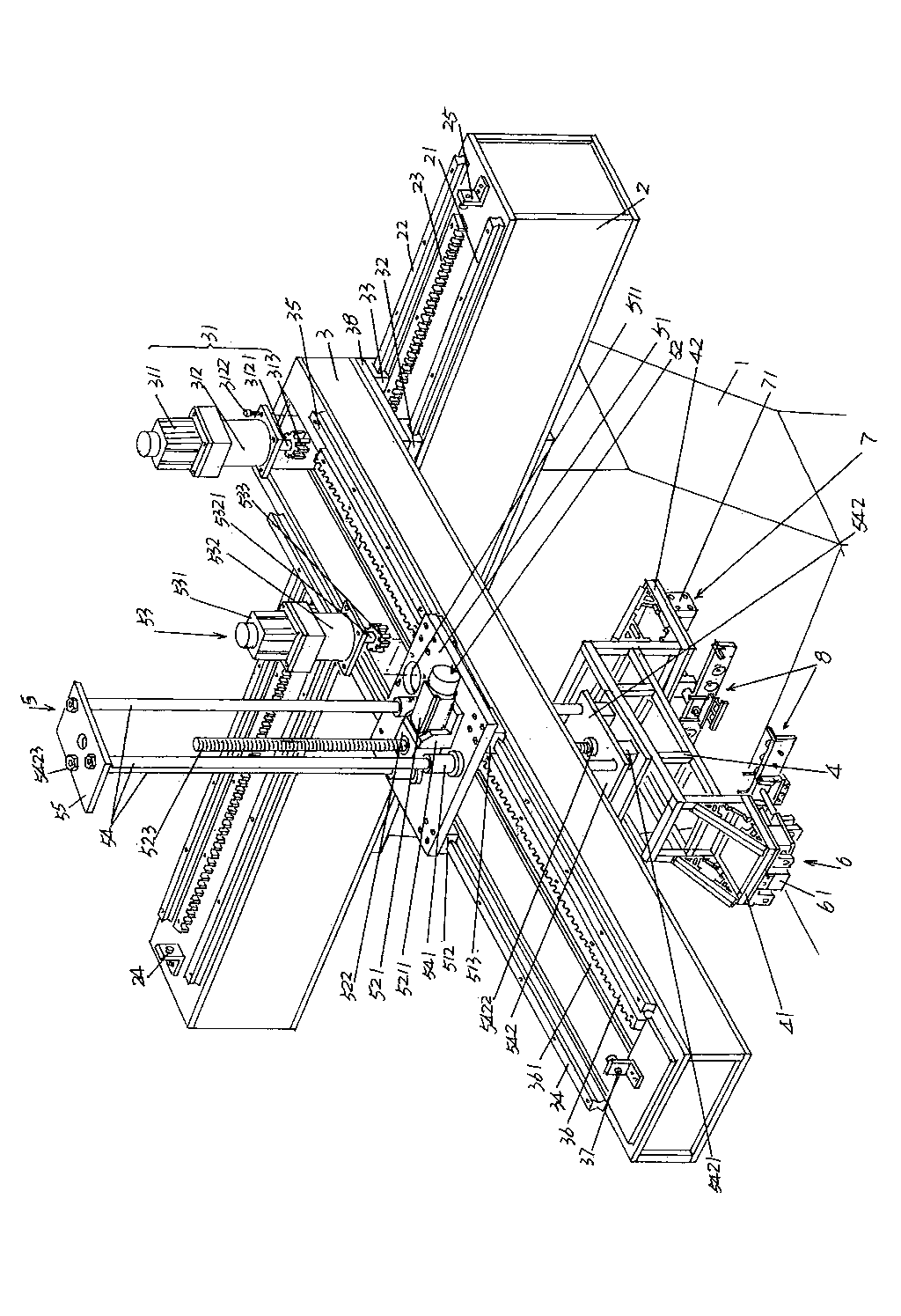

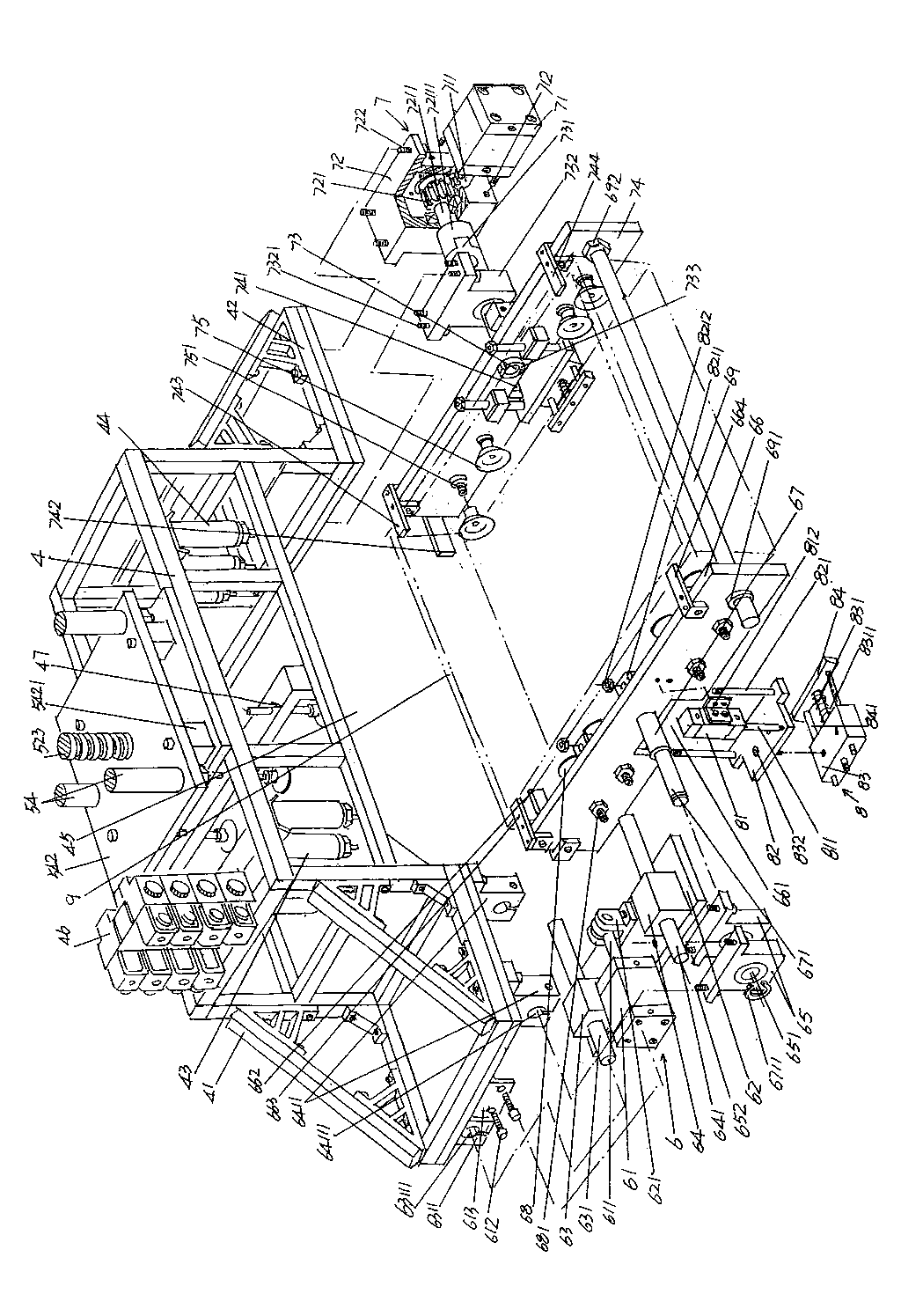

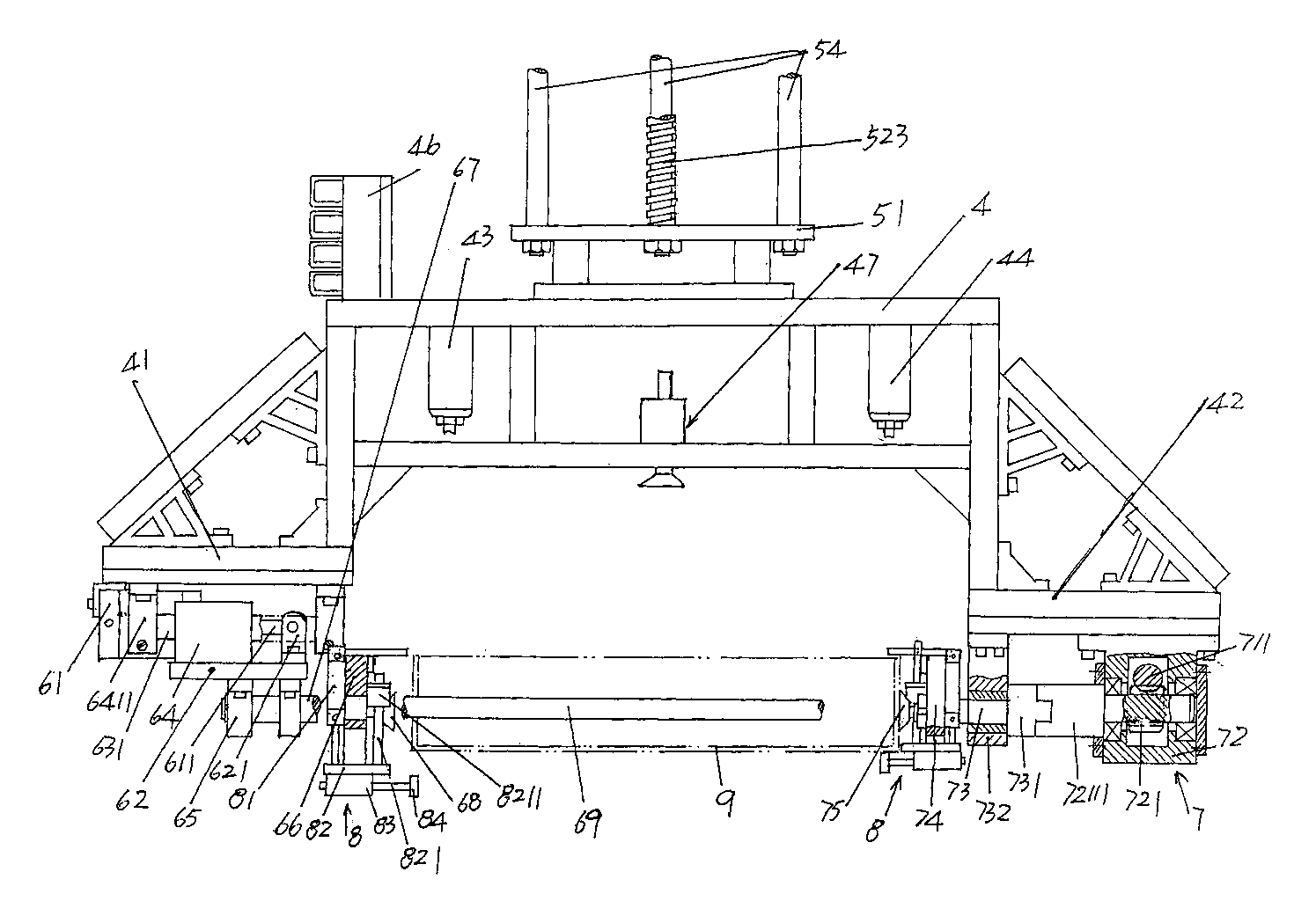

[0023] Please see figure 1 , a frame 1 is given, and the frame 1 is placed at the electronic kiln in the state of use. The electronic kiln mentioned here refers to any One side can also be placed at either end of the two ends of the electronic kiln, that is to say, in the state of use, the frame 1 is accompanied by the electronic kiln, as long as it does not interfere with the electronic kiln, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com