Mobile automatic stirring equipment based on vehicle body and used for building construction

A technology for building construction and mixing equipment, which is applied to mixer accessories, vehicles for freight, mixers with rotating mixing devices, etc., and can solve problems such as inconvenience and operational limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

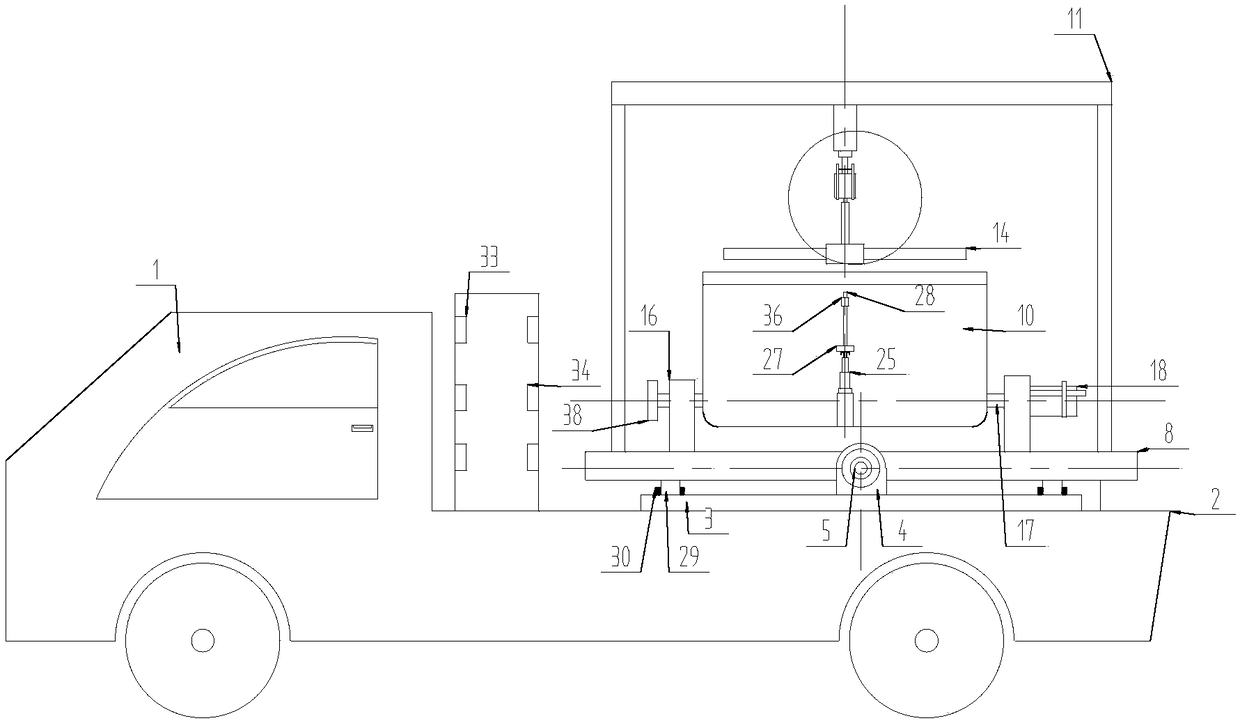

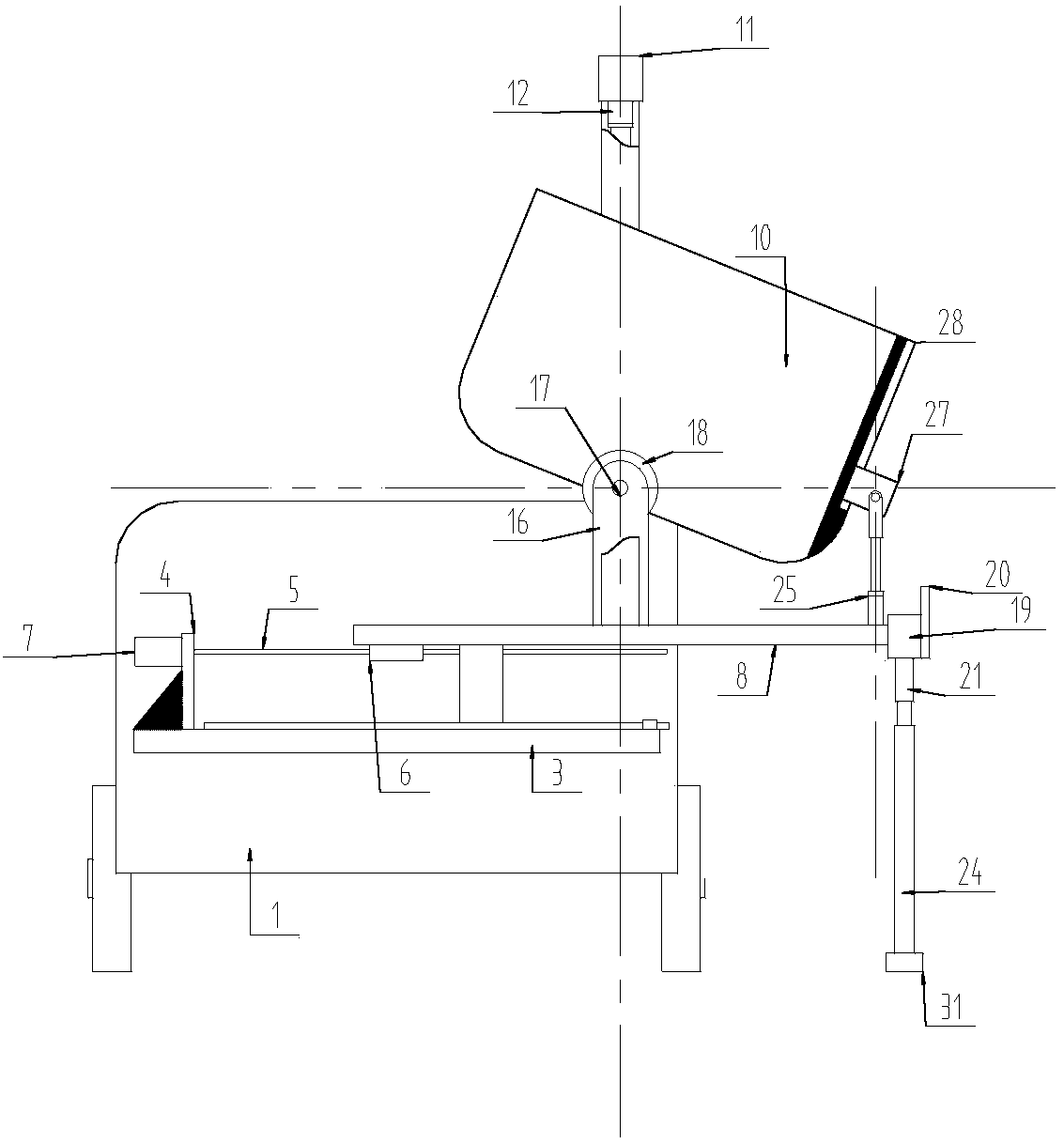

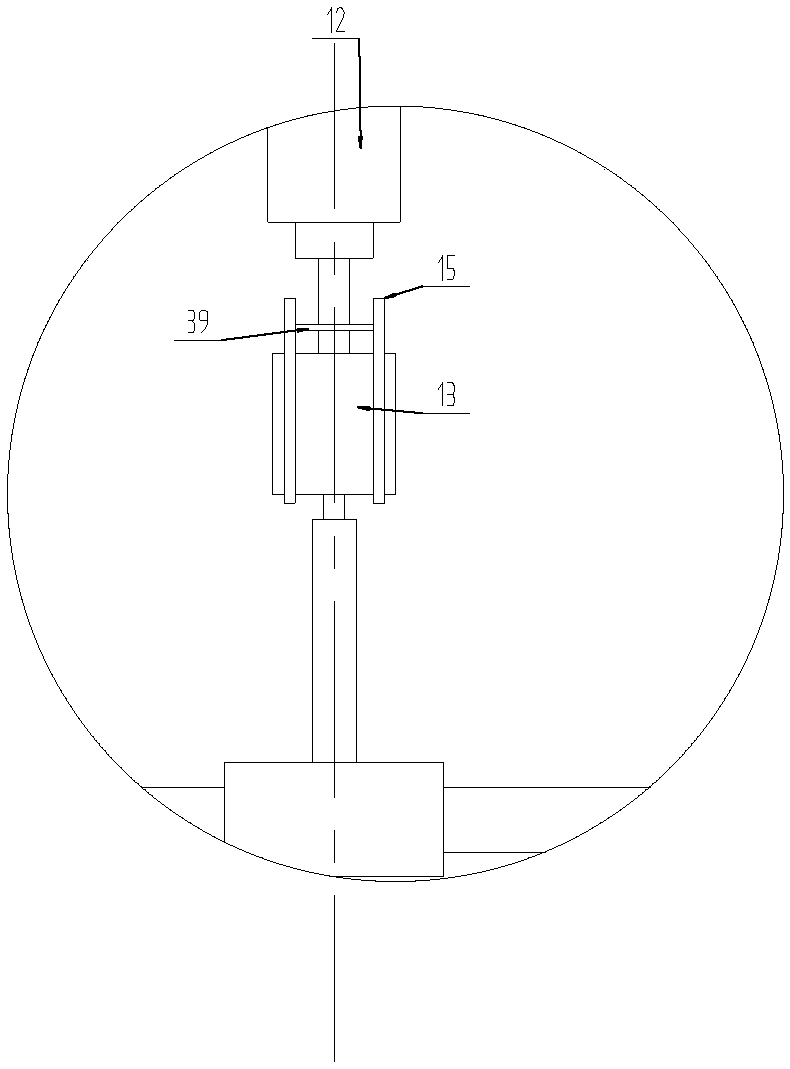

[0046] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6Shown, a kind of mixing equipment based on the mobile automation building construction on the car body, comprises car body 1, has compartment 2 on its car body 1, and the bottom of described compartment 2 is provided with backing plate 3, and this backing plate 3 is provided with mobile Unit, the mobile unit, which includes: a shaft frame 4, a leading screw 5, a screw pair 6, a driver 7, a mounting plate 8 and an auxiliary part; the shaft frame 4 is fixed on the backing plate 3, and the leading screw 5 Inserted on the shaft frame 4, the lead screw pair 6 is set on the lead screw 5, the driving part 7 is fixed on the outer wall of the shaft frame 4, and the driving end of the driving part 7 is connected with the end surface of the leading screw 5. The bottom of the mounting plate 8 is fixed on the lead screw pair 6, and the two ends are fitted on the auxiliary pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com