Automatic and intelligent primer gating system and working method thereof

A technology of pouring system and detonator, applied in the field of intelligent pouring system and automatic relay detonator, can solve the problems of easy material blocking, waste, poor material compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Aiming at the deficiencies of the prior art, the present invention provides an automatic and intelligent pouring system for relay detonators.

[0009] The present invention also provides a working method of the automatic and intelligent pouring system of the relay detonator.

[0010] Technical scheme of the present invention is as follows:

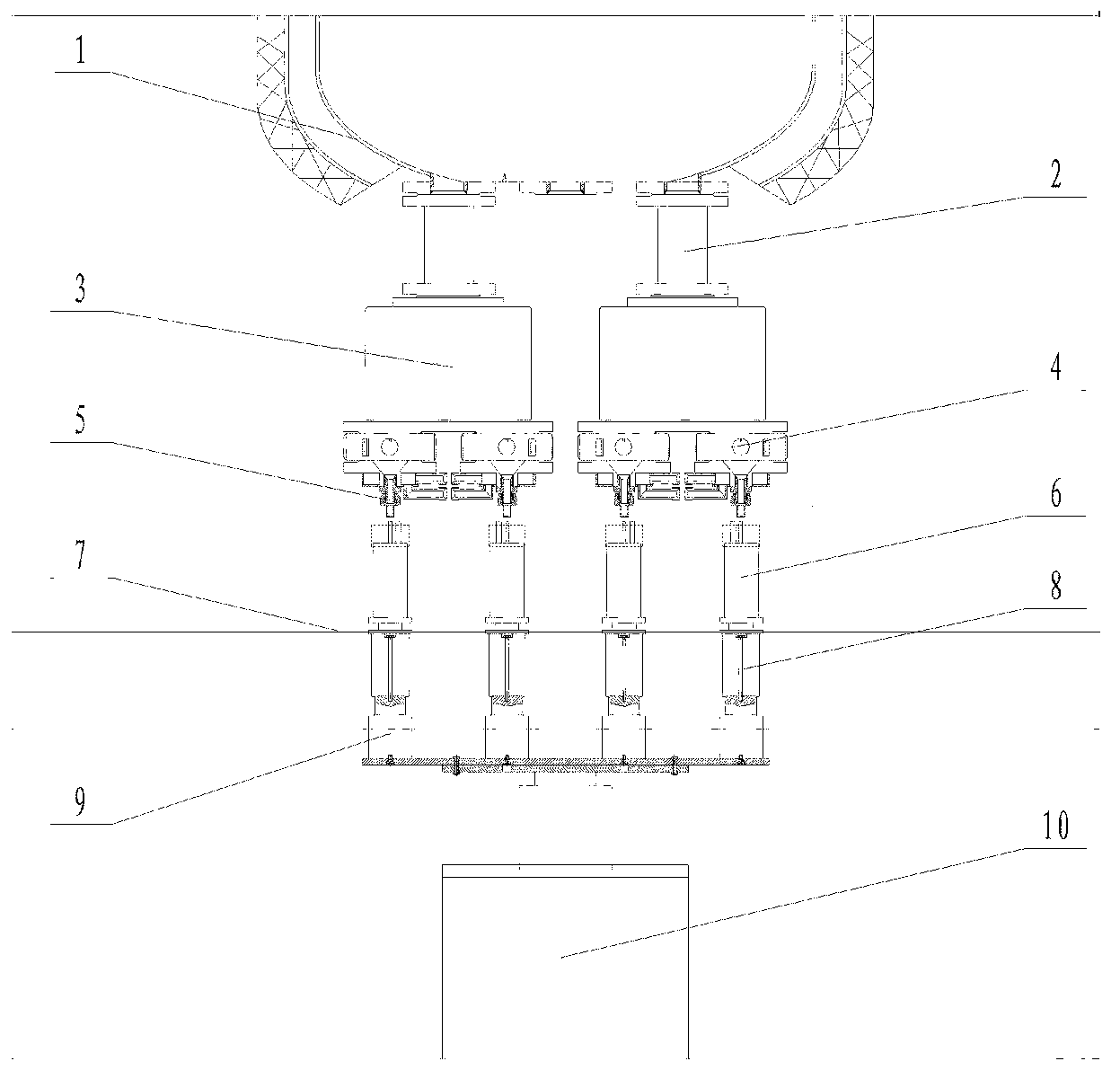

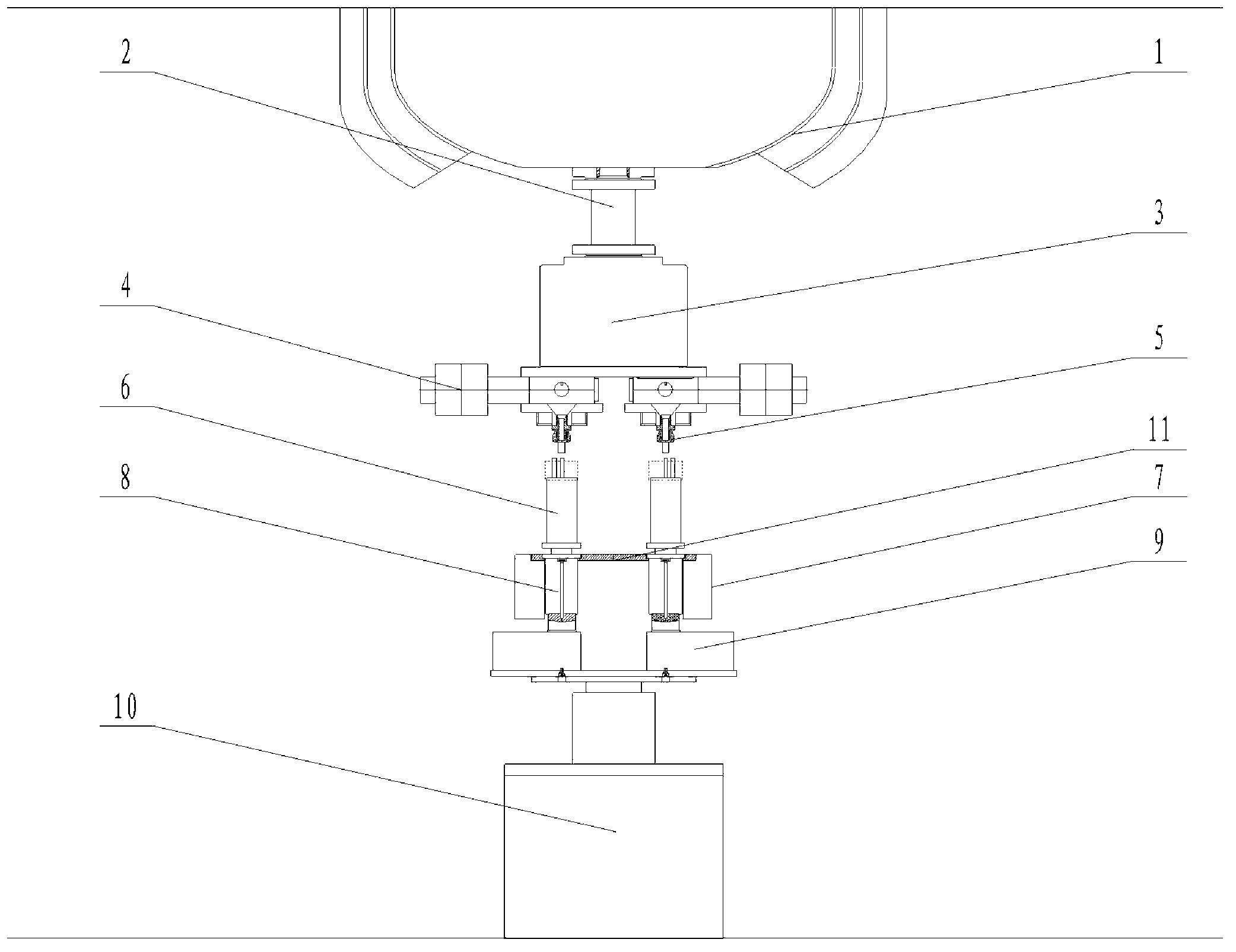

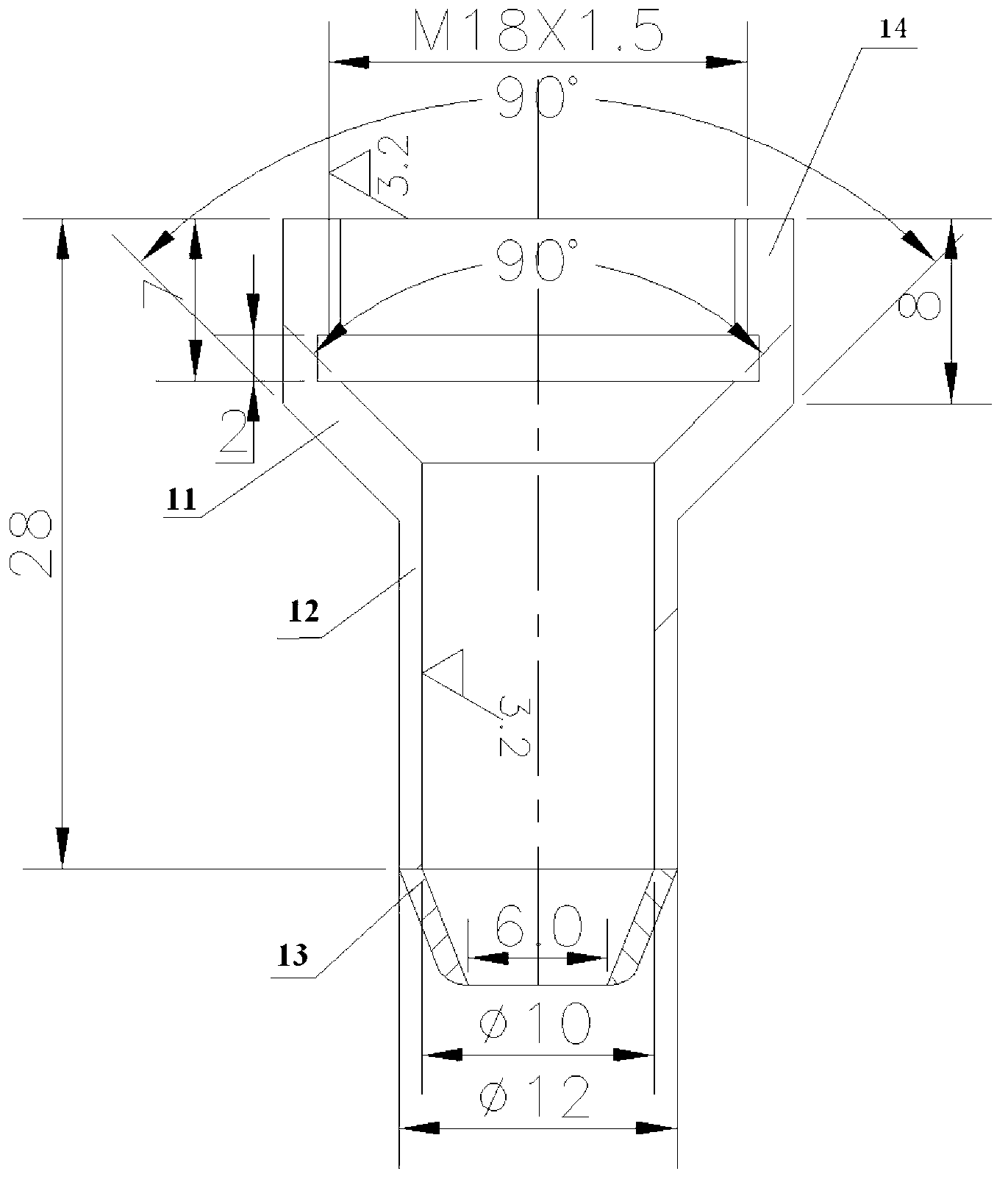

[0011] An automatic and intelligent pouring system for a relay detonator, including a control module and a pouring module, the control module monitors the working state of the pouring module in real time through sensors, and the control module adjusts and controls the pouring according to the monitored working state The module works to realize closed-loop control work; the sensors include temperature sensors and speed sensors:

[0012] The temperature sensor is installed inside the drug injection tank to monitor the temperature of the material in the drug injection tank; the temperature sensor is provided with an isolation conversi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com