Method for improving automatic casting of continuous casting ladle

A technology of continuous casting steel and continuous casting pouring, which is applied in the field of metallurgy, and can solve problems such as damage to production equipment, secondary oxidation of molten steel, unstable billet quality, etc., and achieve the effects of increasing production costs, enhancing the quality of finished products, and improving the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

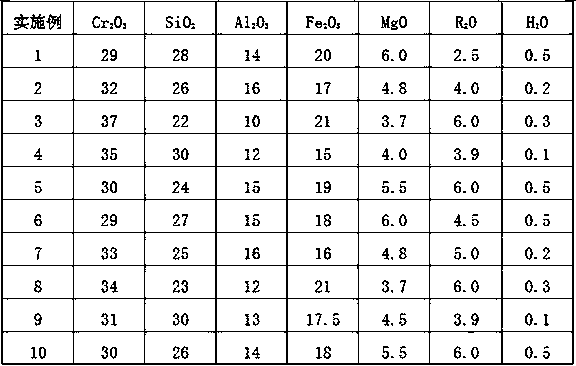

[0022] The chemical composition and mass percentage of low carbon steel in this example are: C: 0.12-0.20%, Si: 0.15-0.25%, Mn: 0.35-0.55%, P≤0.035%, S≤0.035%; the drainage sand is stored The ambient temperature is 25°C and the ambient humidity is 35%. The chemical composition of the drainage sand is shown in Table 1.

[0023] In this embodiment, the method for improving the self-opening of the continuous casting ladle is to carry out data statistics according to one pouring time, including the following steps: control the ladle lining temperature at 871°C before the converter tapping, and control the converter tapping temperature above the liquidus line of the steel type 90°C, no alloy was added during the tapping process of the converter, the flow of argon gas after tapping was controlled at 140L / min, and the time from tapping to continuous casting was controlled at 110min; Open 15 furnaces, the self-opening pass rate is 100%.

Embodiment 2

[0025] The chemical composition and mass percentage of low carbon steel in this example are: C: 0.12-0.20%, Si: 0.15-0.25%, Mn: 0.35-0.55%, P≤0.035%, S≤0.035%; the drainage sand is stored The ambient temperature is 28°C and the ambient humidity is 55%. The chemical composition of the drainage sand is shown in Table 1.

[0026] In this embodiment, the method for improving the self-opening of the continuous casting ladle is to carry out data statistics according to one pouring time, including the following steps: control the ladle lining temperature at 890°C before the converter tapping, and control the converter tapping temperature above the liquidus line of the steel type 90°C, no alloy was added during the tapping process of the converter, the flow of argon gas after tapping was controlled at 150L / min, and the time from tapping to continuous casting was controlled at 130min; 49 furnaces were opened, and the qualified rate of self-opening was 98%.

Embodiment 3

[0028] The chemical composition and mass percentage of carbon steel in this example are: C: 0.28-0.33%, Si: 0.90-1.00%, Mn: 0.95-1.05%, P≤0.020%, S≤0.015%; the drainage sand is stored The ambient temperature is 23°C and the ambient humidity is 55%. The chemical composition of the drainage sand is shown in Table 1.

[0029] In this embodiment, the method for improving the self-opening of the continuous casting ladle is to carry out data statistics according to one pouring time, including the following steps: control the ladle lining temperature at 860°C before the converter tapping, and control the converter tapping temperature above the liquidus line of the steel type 80°C, no alloy was added during the tapping process of the converter, the flow of argon gas after tapping was controlled at 150L / min, and the time from tapping to continuous casting was controlled at 124min; Open 15 furnaces, the self-opening pass rate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com