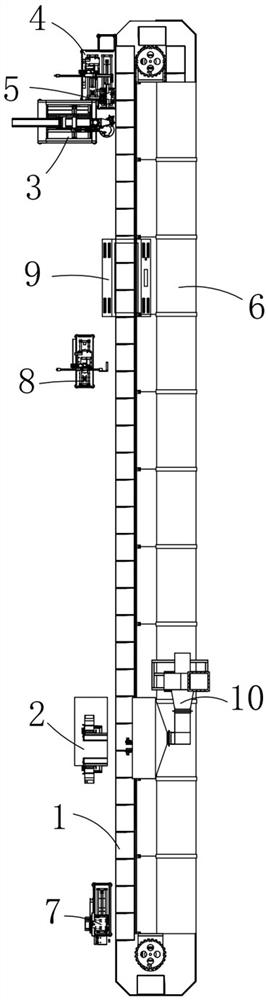

Full-automatic intelligent polyurethane pouring assembly line

A polyurethane, fully automatic technology, applied in the direction of household components, applications, household appliances, etc., can solve problems such as the inability to complete the automatic work of double-layer sole molding, achieve the effect of reducing product production costs and improving product productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

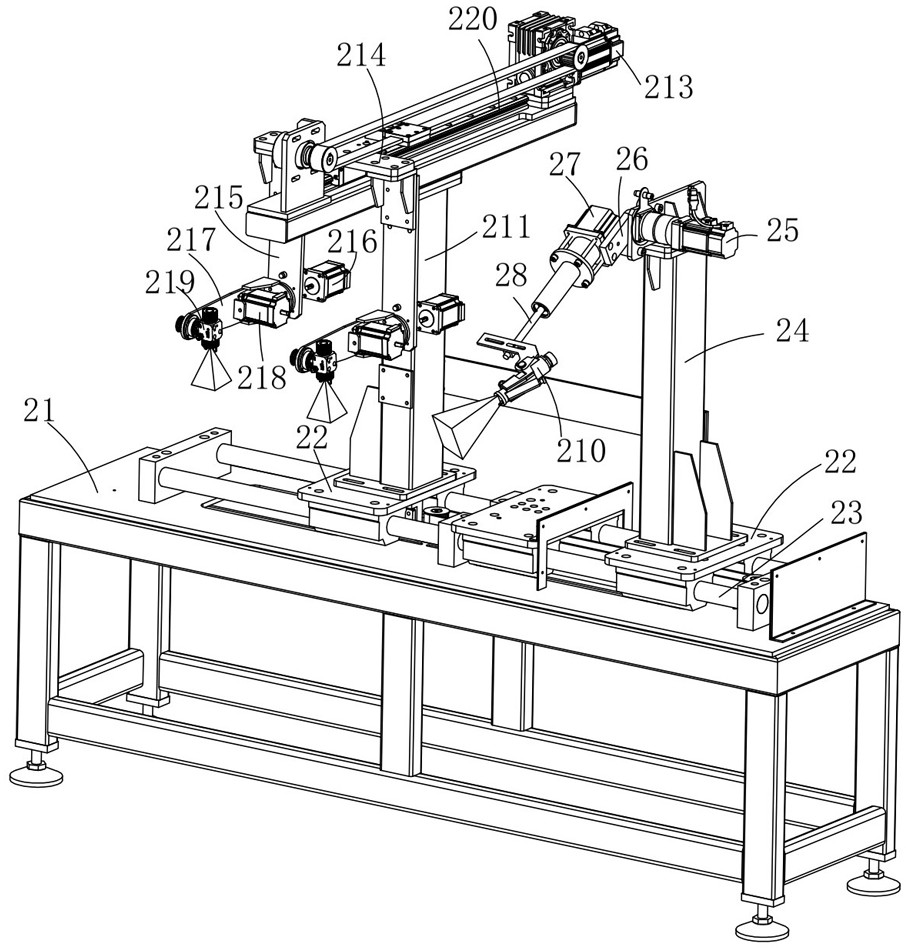

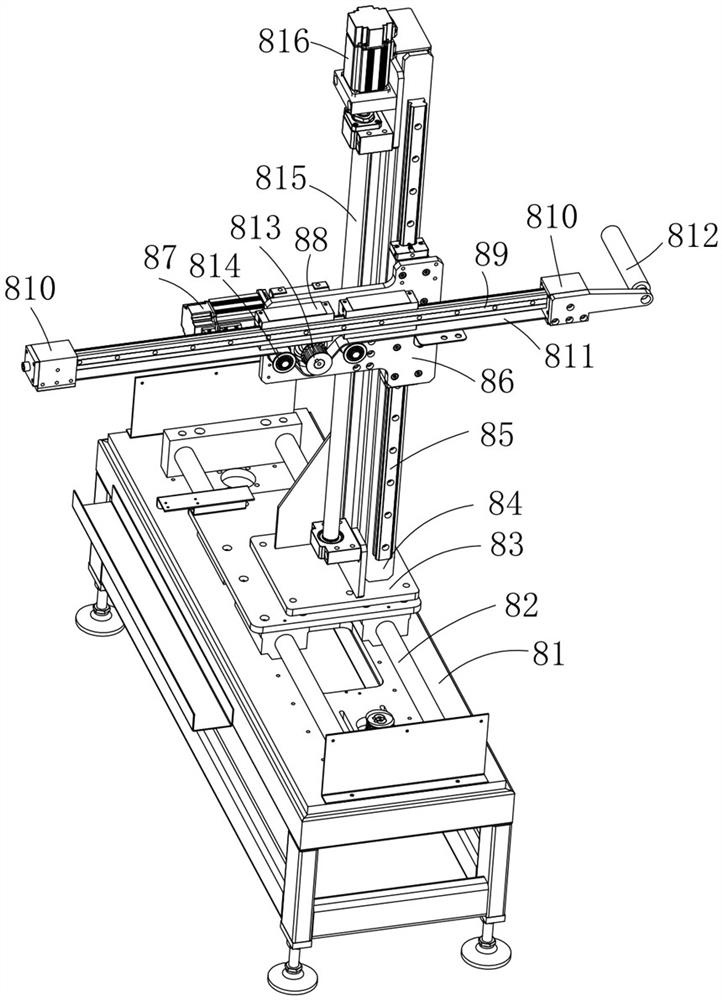

[0021] like Image 6 As shown, as mentioned in the background art, the existing mold includes a main mold A, a transverse mold B and a longitudinal mold C. The main mold A and the longitudinal mold C are hinged together. The longitudinal mold C has a longitudinal wrench C1 and a lock C2. By manually holding the longitudinal wrench C1 and pulling it down, the longitudinal mold C can be flipped vertically, and is parallel to the main mold A At the same time, the lock C2 is buckled on the main mold A, thereby realizing the longitudinal mold clamping; the transverse mold B is hinged on one side of the main mold A, and the transverse mold B has a transverse wrench B2, which can be moved to one side by manually holding the transverse wrench B2 Pull, the transverse mold B can realize lateral flip, and together with the main mold A, and then lock the lock piece A3 on the main mold A to the transverse mold B through the shoe mold locking device 11 (such as Figure 4 As shown, the shoe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com