Powder transferring device

A transfer device and powder technology, applied in the directions of transportation and packaging, packaging, containers, etc., can solve the problems of high labor cost, low transportation efficiency, and can not meet the requirements of modern production, and achieve high transportation and unloading efficiency and labor saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

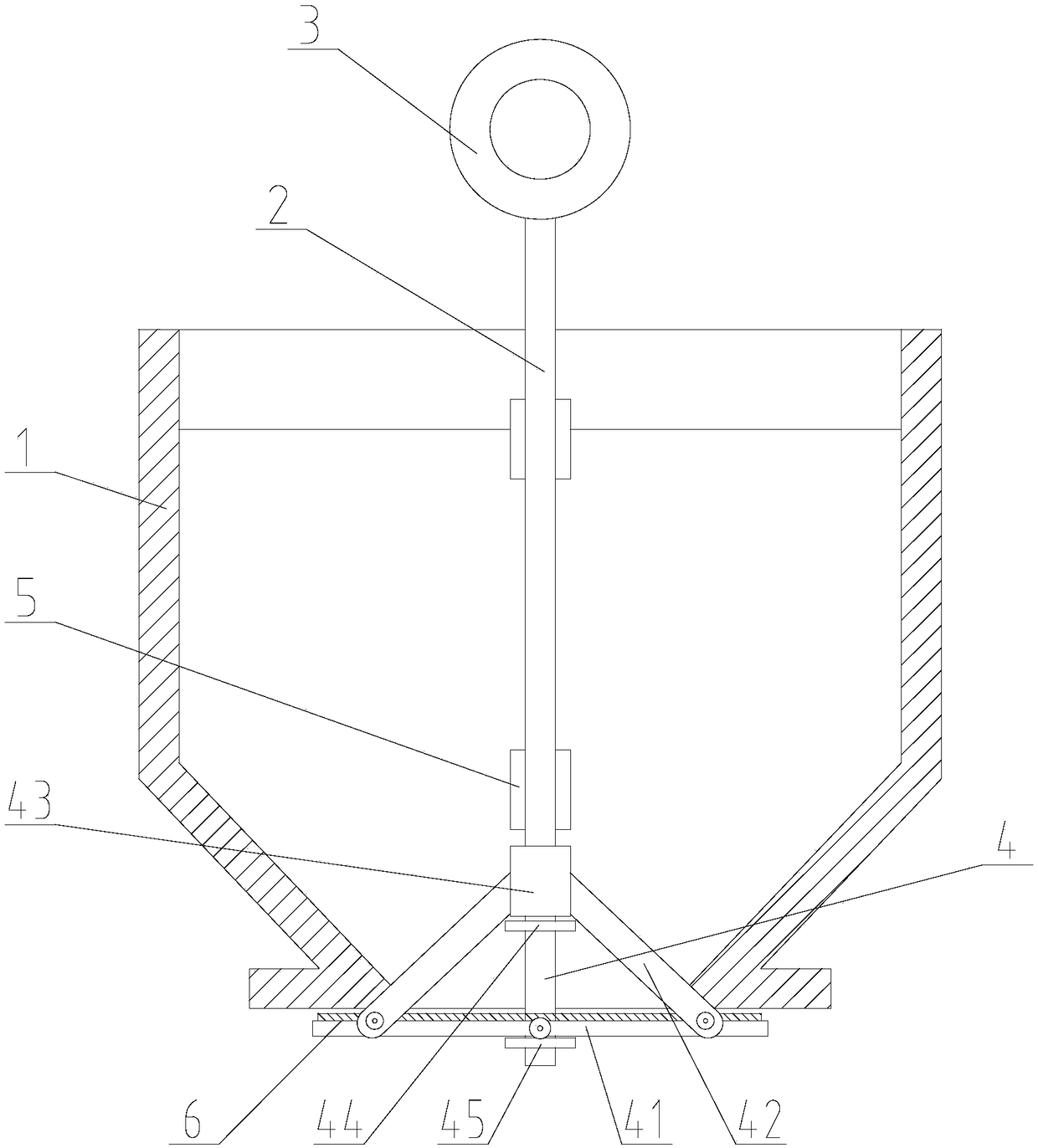

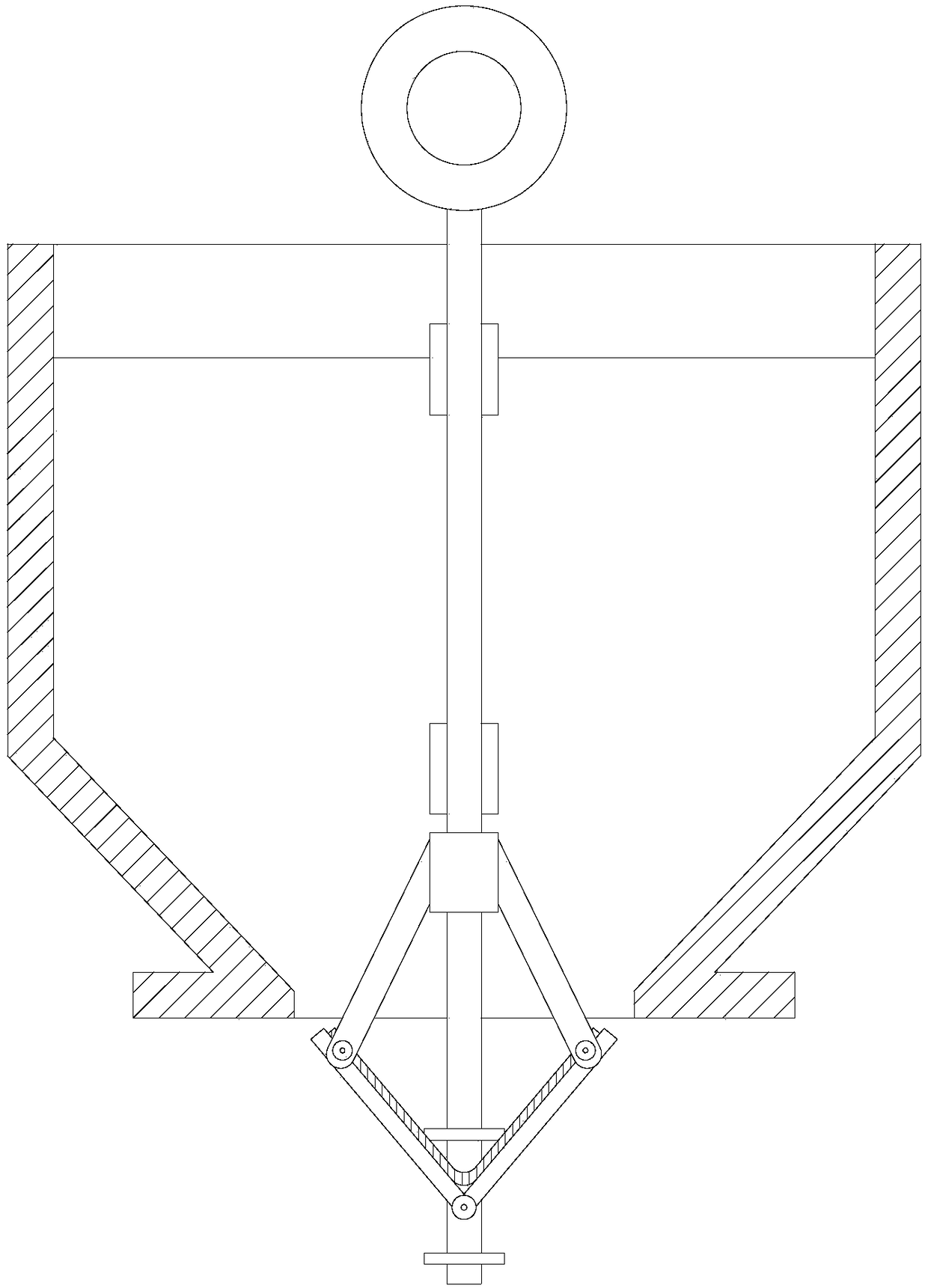

[0015] like figure 1 , figure 2 As shown, the powder transfer device of the present invention includes a storage bin 1 and a movable pull rod 2, the bottom of the storage bin 1 has a discharge port, and the two ends of the movable pull rod 2 are respectively connected to the hook ring 3 and the sealing cone plate 4 , the movable pull rod 2 can move up and down in the storage bin 1; the sealing cone plate 4 is composed of a bottom plate 41, a side plate 42 and a casing 43, the bottom plate 41 is composed of two flat plates hinged, the bottom plate 41 is located outside the discharge port, and the bottom plate When 41 is unfolded, the area is larger than the discharge port, so as to ensure that the seal of the discharge port will not leak. One end of the two side plates 42 is hinged with the bottom plate 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com