Knocking device for fiber bar stocks

A fiber rod and percussion hammer technology, which is applied in packaging and other directions to achieve the effects of convenient use, good vibration effect and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

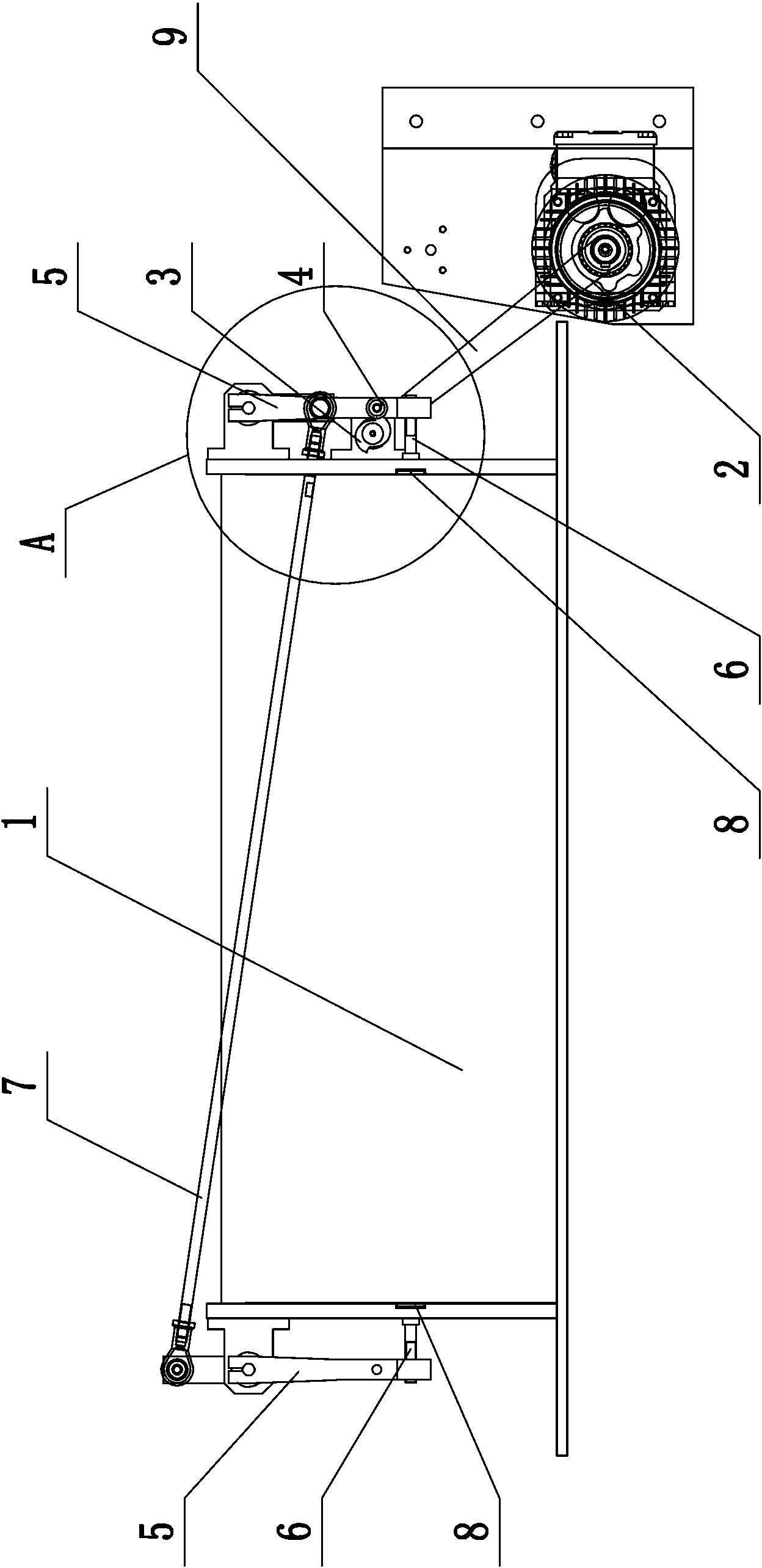

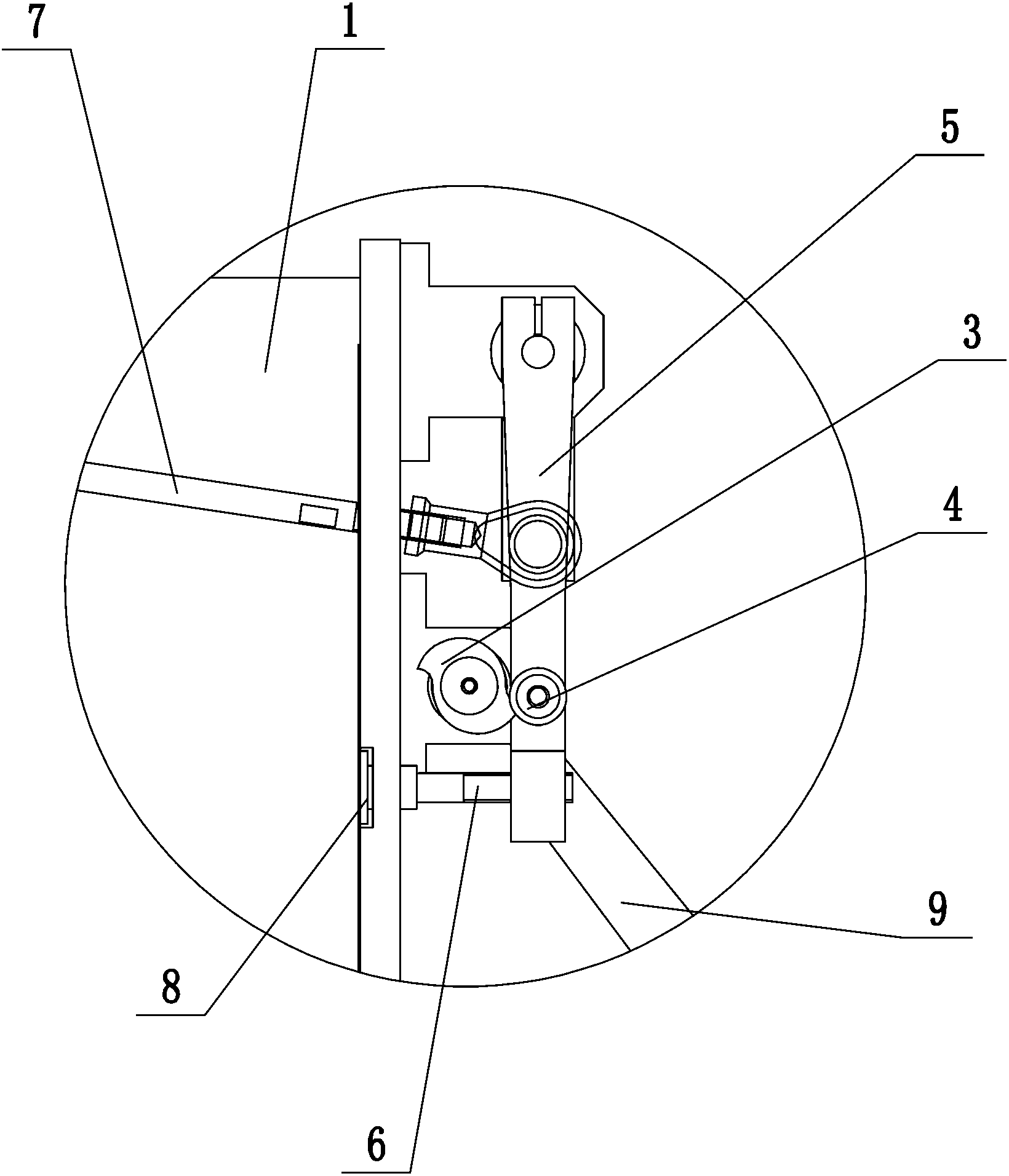

[0023] like figure 1 , figure 2 As shown, a fiber bar percussion device includes a motor 2, a transmission device 9, a cam 3, a driven wheel 4, a pendulum rod 5 and a percussion hammer 6, the motor 2 is a servo motor 2, and the transmission The device 9 is a belt drive, the motor 2 drives the cam 3 to rotate through the transmission device 9, the cam 3 and the side plate of the sorting box 1 are movably connected through bearings, the cam 3 and the driven wheel 4 cooperate with each other, and the driven wheel 4 is arranged in the middle of the swing rod 5, The swing rod 5 is hinged with the side plate of the sorting box 1, and a swing rod 5 is hinged on the left and right side plates of the sorting box 1. The upper end of one swing rod 5 is hinged with one side plate of the sorting box 1, and the other swings The middle of the rod 5 is hinged with anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com