Multi-brush-head cleaning brush with composite working mode

A working mode, multi-brush head technology, applied in the direction of brushes, brush bodies, household appliances, etc., can solve problems such as difficult to achieve long-distance vibration, and small slots cannot be effectively cleaned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

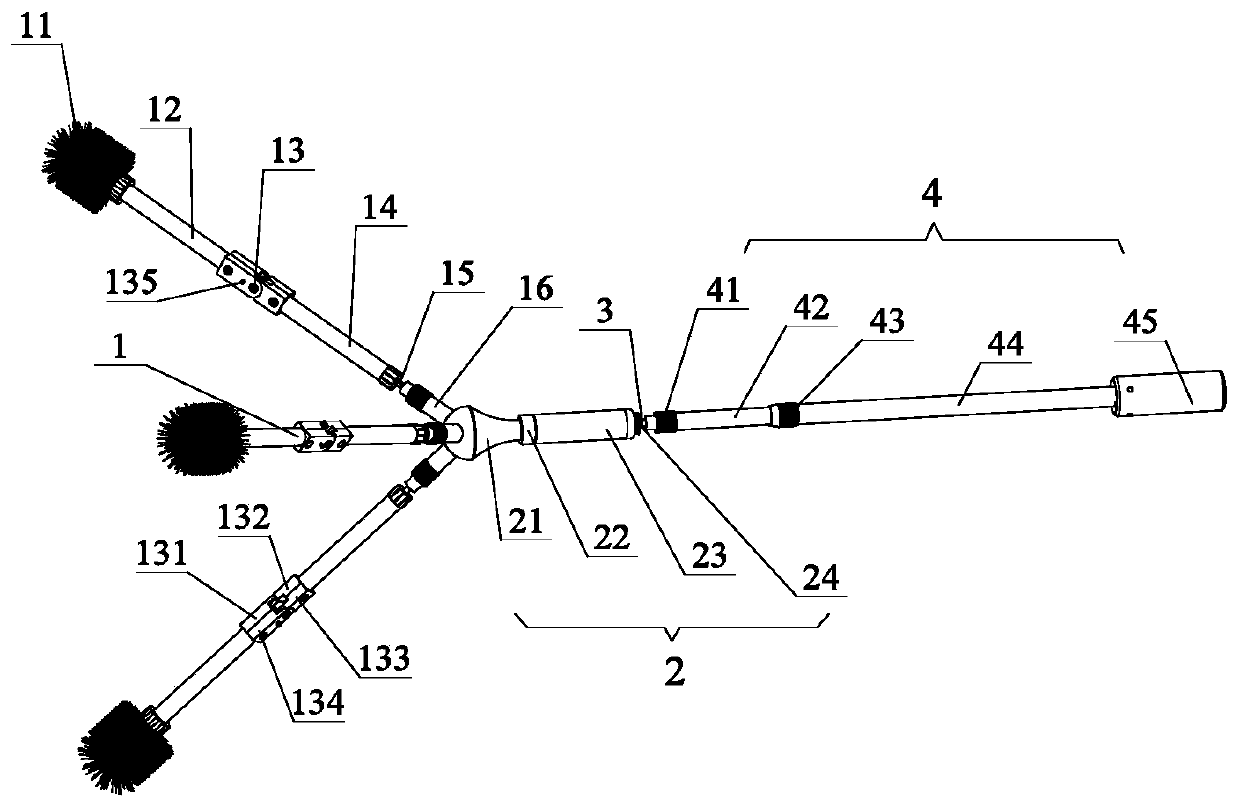

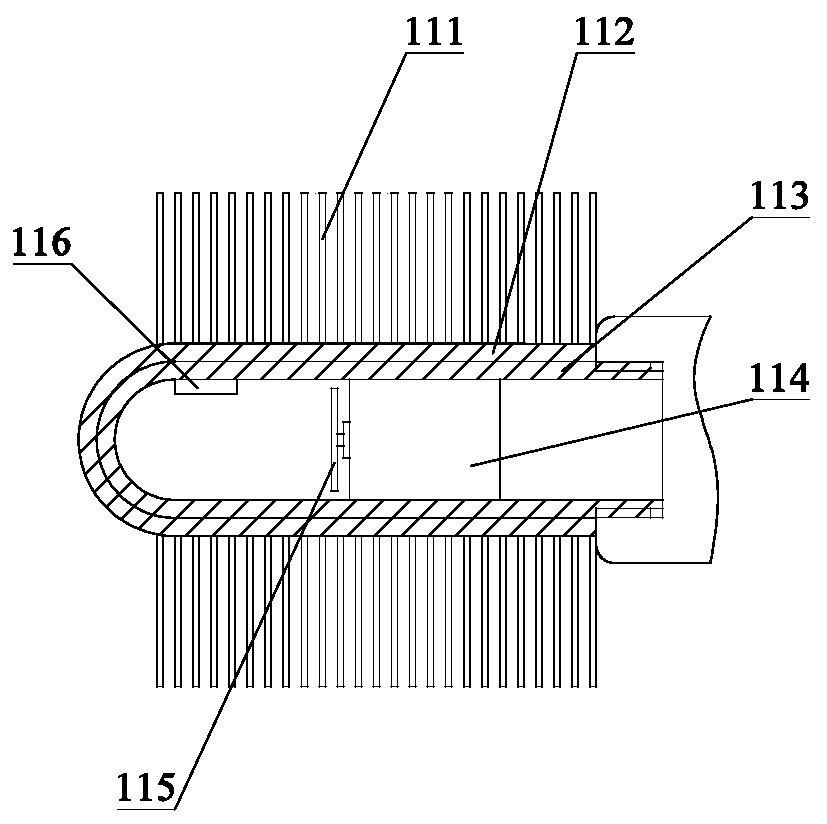

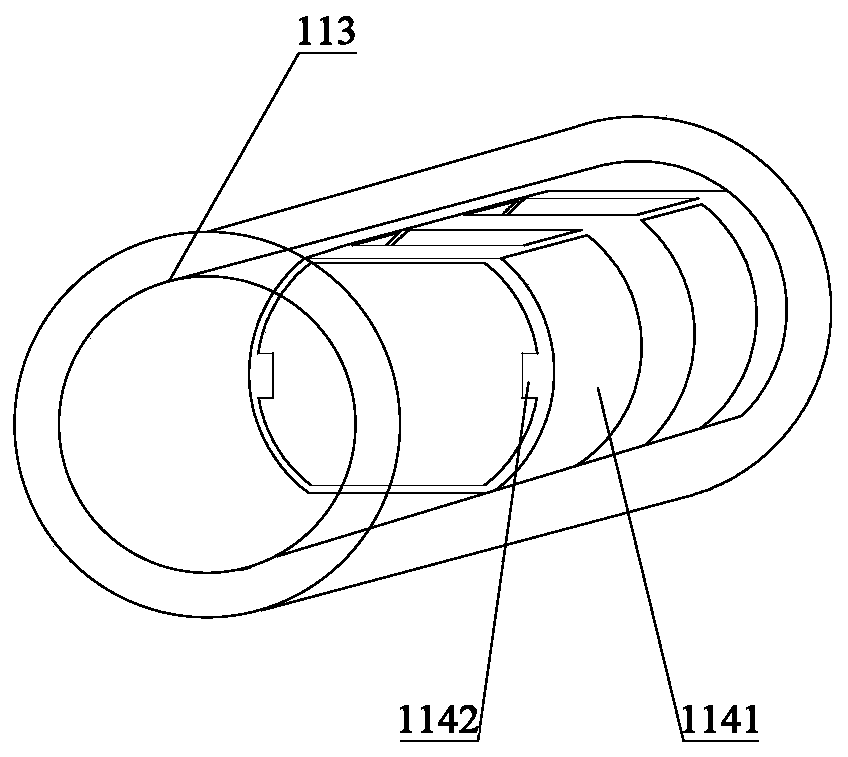

[0051] Such as Figure 1-8 As shown, a cleaning brush with multiple brush heads in a compound working mode includes a rotating mechanism 2, a universal rotating shaft II 3 and a control handle 4 with a power supply. The tail end of the rotating mechanism 2 is connected to the steering end of the universal rotating shaft II 3. The fixed end of the axis II3 is connected to the head end of the control handle 4, and also includes three vibration cleaning mechanisms 1, the vibration cleaning mechanism 1 includes a vibration brush head 11, a connecting rod I12, a lockable hinge 13, a connecting rod II14, and a universal The rotating shaft I15 and the connecting rod III16, the vibrating brush head 11 are detachably sealed and connected with the head end of the connecting rod I12, the tail end of the connecting rod I12 is fixedly connected with the head end of the lockable hinge 13, and the tail end of the lockable hinge 13 It is fixedly connected with the head end of the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com