A light-duty steel-concrete prefabricated floor pouring molding machine with shaped lightweight filler

A molding machine and filling material technology, which is applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problem of one-time simultaneous pouring of prefabricated bottom plates that cannot meet the production requirements of prefabricated bottom plates of laminated floor slabs and cannot realize new laminated floor slabs. Forming and other problems to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

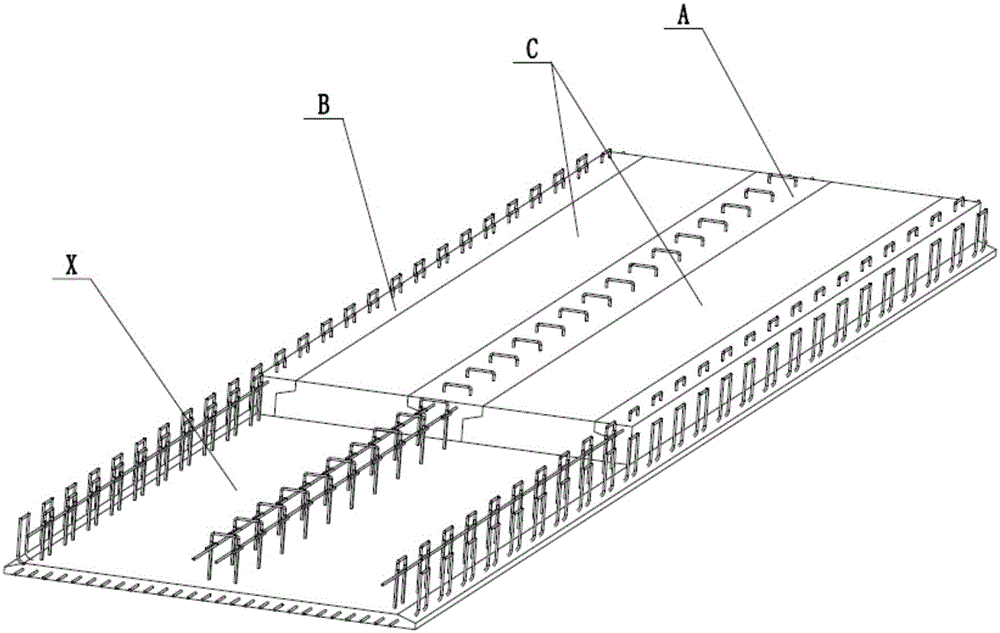

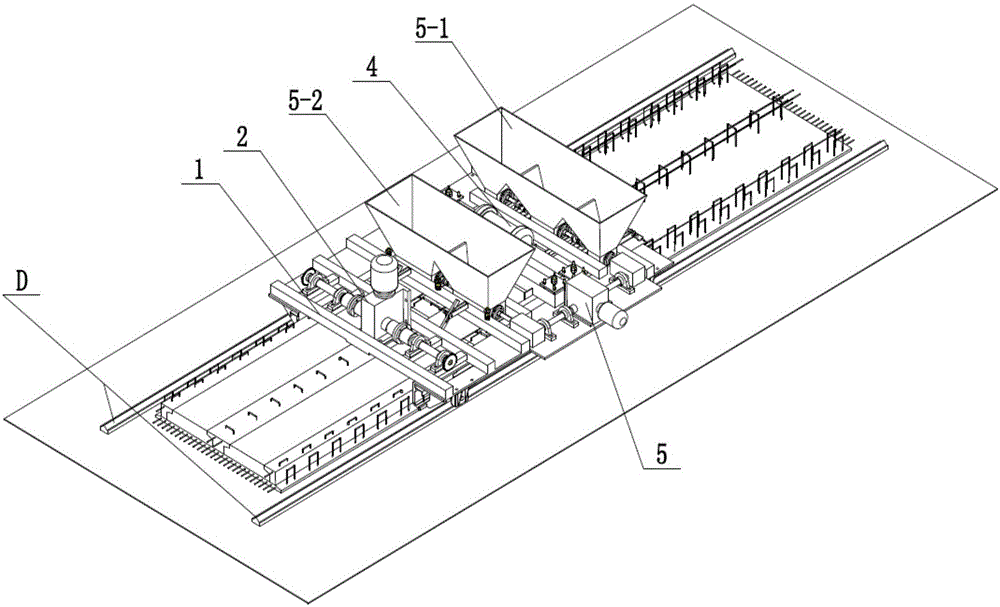

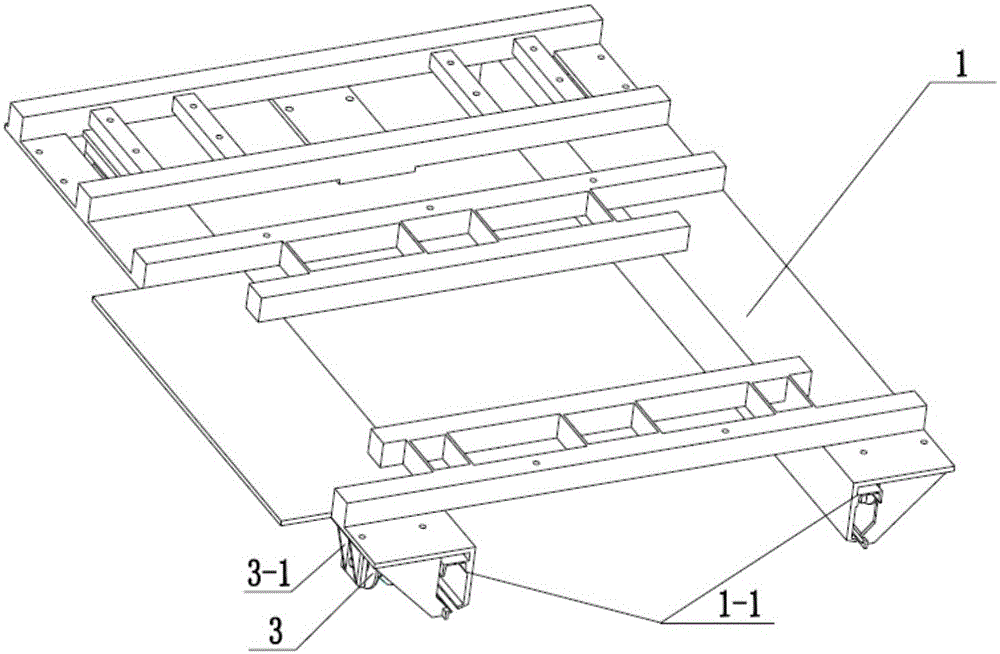

[0018] How to implement the present invention will now be further explained in conjunction with the drawings:

[0019] The present invention is a light-weight steel-concrete prefabricated bottom plate pouring molding machine with molded light-weight fillers, see figure 2 , Including frame 1, driving wheel system 2, guide wheel system 3, vibration forming system 4 and material system 5. The frame 1 is composed of longitudinal two sides of the template 1-1 and horizontal fixed beams, the guide wheel system 3 Two sets of guide wheel sets are respectively arranged on both sides of the front end of the frame 1 through the guide wheel support 3-1, see image 3 , The two drive wheel sets 2-1 of the drive wheel system 2 are respectively fixed on both sides of the rear end of the frame 1 through the drive wheel supports 2-1a; the drive wheel sets are driven by the motor to run synchronously, and the frame follows the ground track D operation; vibration forming mechanism 4 is composed of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com