Concrete vibrating rod inserting and pulling speed regulating device for building construction

A technology of building construction and speed control device, applied in construction, building structure, processing of building materials, etc., can solve problems such as operation errors, concrete holes, and high requirements for workers' operating experience, so as to reduce the difficulty of operation, avoid skew, Guaranteed effect of vibrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

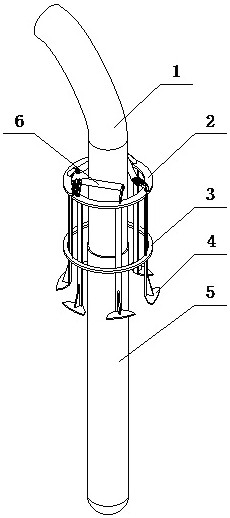

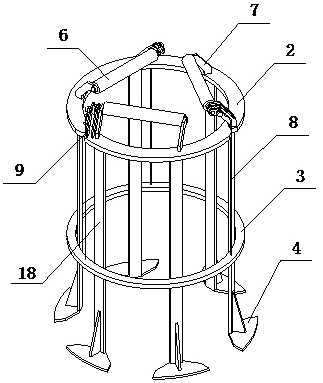

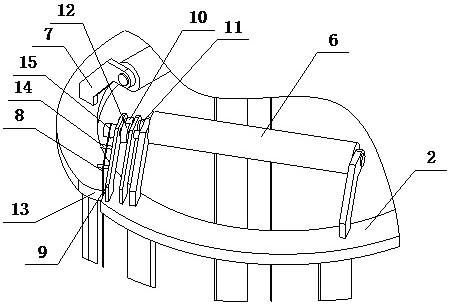

[0016] A kind of concrete vibrating rod plug-in speed regulating device for building construction of the present invention is realized in this way: a kind of concrete vibrating rod plug-in speed regulating device for building construction of the present invention is made up of main body device and speed regulating device, and main body device is supported by Plate (2), counterweight ring (3), bottom support (4) and connection plate (18), the support plate (2) is an annular plate structure, one end of a plurality of connection plates (18) and the support The bottoms of the boards (2) are equiangularly connected, the other end of the connecting board (18) extends downwards, and the bottom brace (4) is placed on the other end of the connecting board (18), the bottom brace (4) and There are reinforcing ribs between the connecting plates (18), the counterweight ring (3) is located under the support plate (2), and is close to the other end of the connecting plate (18), and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com