Flour processing vibrating screen

A vibrating screen, flour technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of accumulation and poor screening effect, and achieve the effect of ensuring the vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

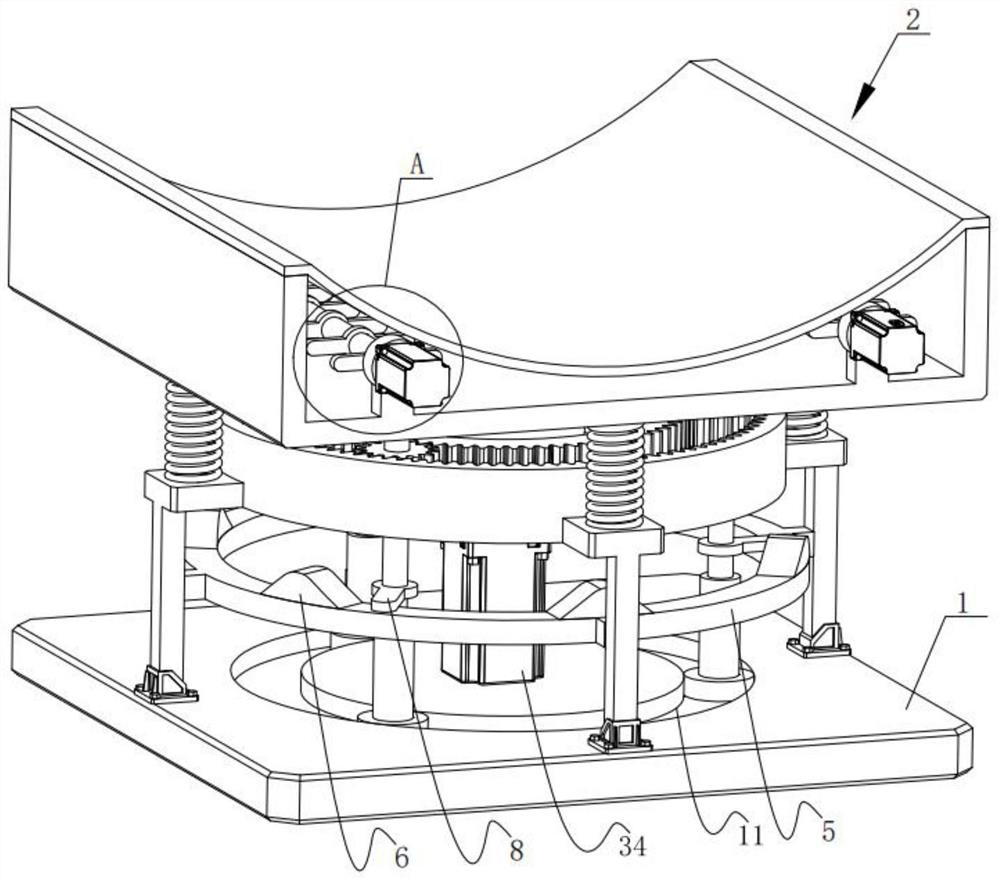

[0026] see Figure 1 to Figure 5 , the present invention provides a technical solution:

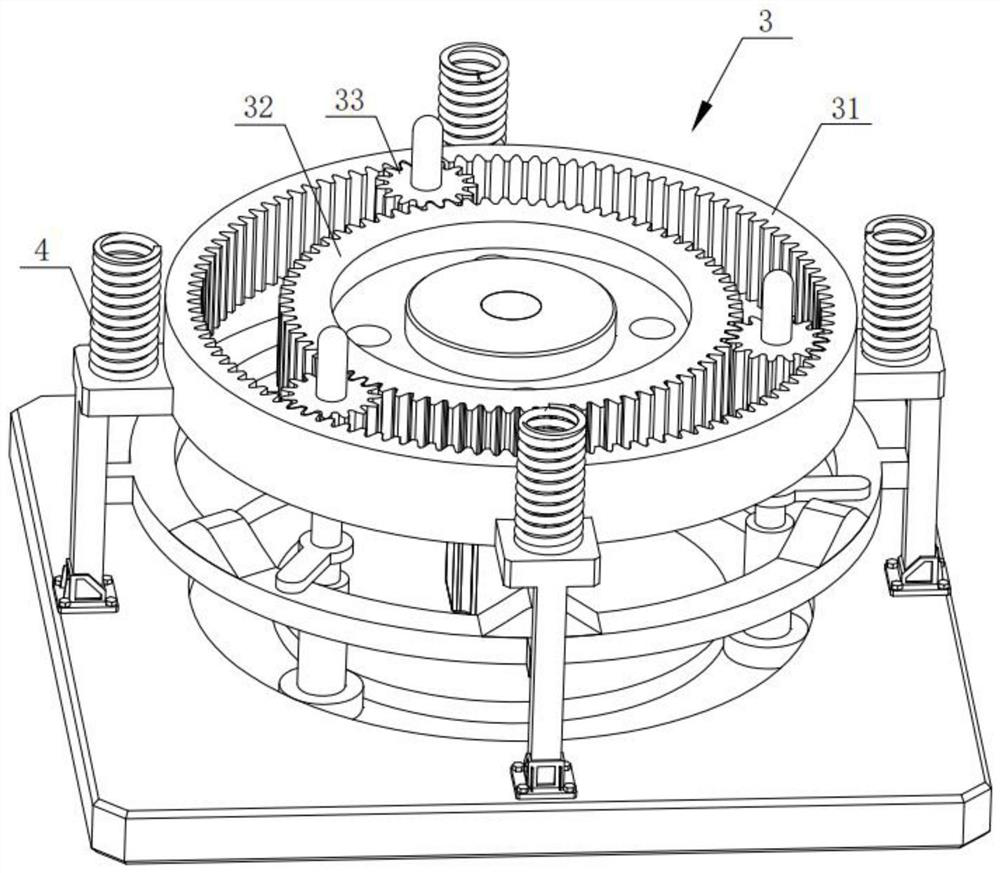

[0027] A vibrating screen for flour processing, including a frame 1, a screening assembly 2, a planetary gear set 3, a spring I4, a ring 5, a raised part 6, a telescopic rod assembly 7 and a baffle 8, wherein:

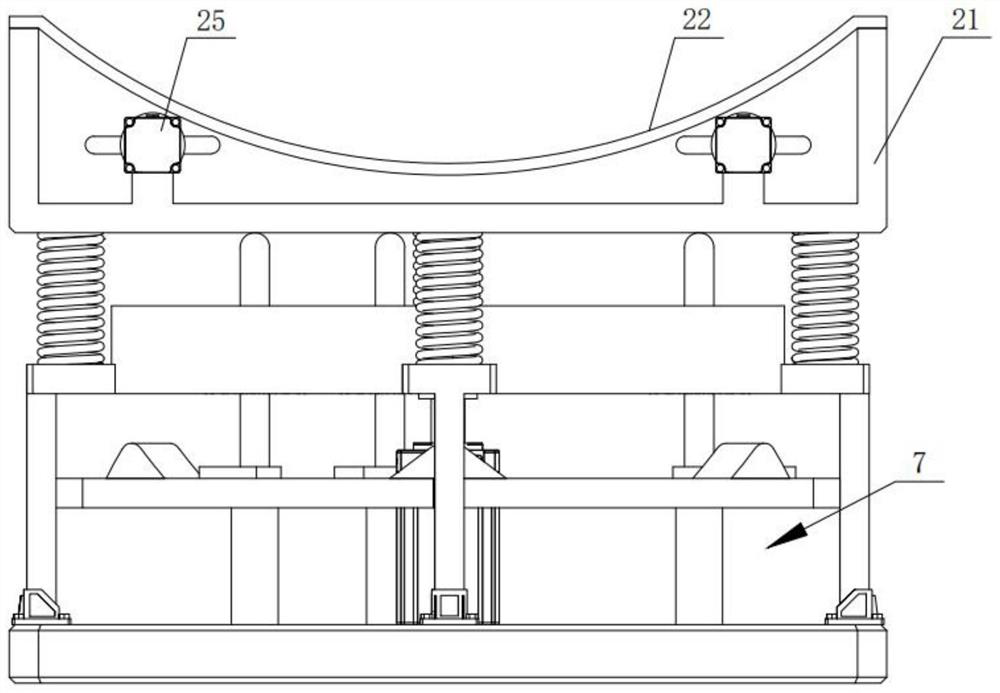

[0028] The screening assembly 2 includes a support frame 21, a filter cloth screen 22, a rotating shaft 23, a lever 24 and a motor I25. The support frame 21 is set on the inner ring gear 31 through the spring I4, wherein the spring I4 is connected to the support of the inner ring gear 31. The rod is fixedly connected, and the other end of the spring I4 is fixedly connected with the support frame 21, and the support frame 21 is installed as a flexible connector, which can move in the direction of the external force when it is subjected to external force, and the two sides of the filter cloth screen 22 The end is connected with both sides of the support frame 21, forming an arc sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com