Belt conveying system for transportation of bulk materials

A technology for belt conveying and bulk materials, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor production environment and low conveying efficiency, achieve enhanced compactness, improve conveying efficiency, and reduce sticking or oscillating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

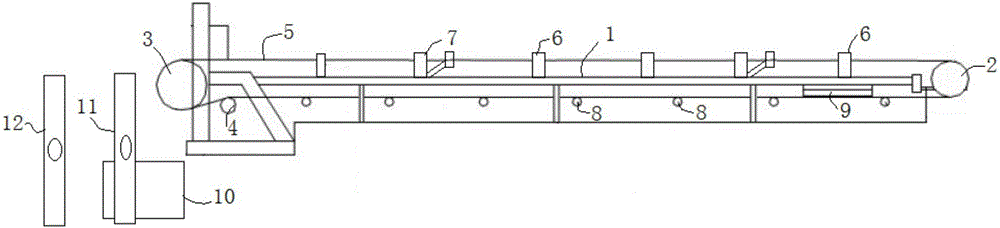

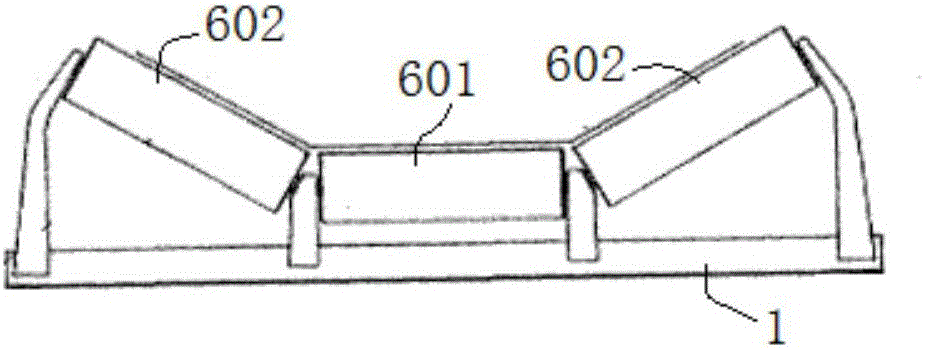

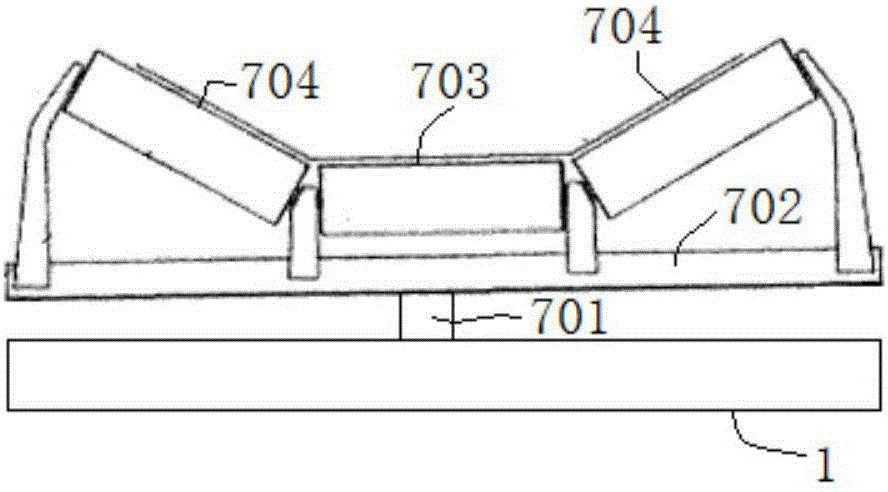

[0064] A kind of belt conveying system that is used for bulk material transportation of present embodiment, comprises frame 1, as figure 1 As shown, the two ends of the frame 1 are respectively provided with a transmission head wheel 2 and a transmission tail wheel 3, and the conveyor belt 5 is covered and driven by the transmission head wheel 2 and the transmission tail wheel 3, and the lower side of the transmission tail wheel 3 Also be provided with transmission auxiliary wheel 4, the outside of transmission head wheel 2, transmission tail wheel 3 and transmission auxiliary wheel 4 are all wrapped with a layer of wear-resistant rubber along the circumferential direction, and the surface turning of wear-resistant rubber has rhombus or herringbone pattern, can Effectively enhance the transmission friction with the conveyor belt 5, and drive the conveyor belt 5 to run smoothly. During the material conveying process, the upper conveyor belt 5 is supported by the top idler, and ...

Embodiment 2

[0073] A belt conveying system for bulk material transportation in this embodiment is basically the same as that in Embodiment 1. Further, the primary monolithic device 11 in this embodiment includes a first gantry 1101, a vibrating installation beam 1106 and a vibrating rod 1107, Specific as Figure 6 , Figure 7 and Figure 8 As shown, the first top beam 1103 on the top of the first gantry 1101 is provided with a first traction wheel 1104, the top of the first gantry 1101 is provided with a first winch 1102, and the traction wire 1105 on the first winch 1102 passes through the first A traction wheel 1104 is connected with the vibration installation beam 1106, the vibration installation beam 1106 is located below the first top beam 1103, the vibration rod 1107 is arranged on the vibration installation beam 1106, and the first winch 1102 drives the vibration installation beam 1106 along the first gantry 1101 The first gantry 1101 is also provided with a limit switch for cont...

Embodiment 3

[0080] A belt conveying system for bulk material transportation in this embodiment is basically the same as in Embodiment 2. Further, in this embodiment, the re-integrating device 12 includes a second gantry 1201, a lifting bracket and a monolithic pressure roller, such as Figure 10 , Figure 11 and Figure 12 As shown, the top of the second gantry 1201 is symmetrically provided with two side brackets 1205, and the second top beam 1204 is fixedly connected between the two side brackets 1205. The second top beam 1204 is evenly spaced with supporting pulleys. The winch 1202 is arranged on the second gantry 1201, and the top of the lifting bracket is provided with a hoisting wheel 1210, and the hoisting steel wire 1203 on the second winch 1202 passes through the support pulley on the second top beam 1204 to be connected with the hoisting wheel 1210, and the whole material is pressed The rollers are arranged below the lifting bracket. This embodiment also uses two symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com